MAINTENANCE

SCHEDULE

NOTE:

Use

the

engine hourmeter

gauge

to

log

your engine hours or

record

your engine hours

running

time.

SCHEDULED

MAINTENANCE

EXPLANATION

OF

SCHEDULED

MAINTENANCE

I

EVERY

250

OPERATING

HOURS

OR

YEARLY

Hoses

•1gnltlon

Timing

-------

•spark

Plugs

Engine

hoses

should

be

firm

and

tight.

Replace

if

hoses

become

spongy,

brittle

or

delaminated.

Check

and

tighten

all

hose

clamps

as

needed.

Check

timing

and

adjust

as

needed.

·~-----------

1

nspect,

clean,

re-gap

or

replace.

•Vibration

lsolalorsJEngine

Mounts

----------------------------~-~~-.

Check

vibration

isolators,

brackets

and

mounting

hardware.

Replace

as

needed.

Heat

Exchanger

Mechanical

Governor

Open

heat

exchanger

and

cap(s)

and

clean

out

debris.

Replace

gasket

and

0-rings

if

needed.

-~--------~·-

.

Change

governor

oil.

I

EVERY

500

OPERATING

HOURS

OR

YEARLY

Raw

Water

Pump

Remove

the

pump

cover

and

inspect

the

pump

assembly

for

wear,

especially

cam

and

wear

plates.

Replace

the

impeller

and

gasket.

Lubricate

the

impener

at

re-assembly.

•Exhaust

System

catalyst

I

EVERY

500

OPERATING

HOURS

OR

EVERY

TWO

YEARS

Ignition

Wires

•Coolant

System

Inspect

and/or

replace.

See

Data

below.

*

Inspect

for

deterioration.

Inspect

resistance.

Drain,

flush

and

re-fill

the

cooling

system

with

appropriate

antifreeze

mix.

Replace

the

thermostat

and

coolant

pressure

cap.

·-------------~·

•valve

Clearances

Adjust

valves.

(Incorrect

varve

clearance

wiH

result

in

poor

engine

performance.

*starter

Motor

Check

solenoid

and

motor

for

corrosion.

Remove

and

lubricate.

Clean

and

lubricate

the

starter

motor

pinion

drive.

EVERY

1000

OPERATING

HOURS

OR

OR

EVERY

FIVE

YEARS

•Engine

Timing

Belt

Inspect

timing

belt.

Replace

as

needed.

Failure

to

replace

belt

can

result

in

severe

engine

damage.

Heat

Exchanger

Cylinder

Head

Bolts

Remove

the

heat

exchanger

for

professional

cleaning

and

pressure

testing.

Re-torque

bolts

(engine

cold).

Adjust

valves

after

re-torque.

NOTE:

Keep

the

engine

surface

clean.

Dirt

and

oil

will

inhibit

the

engine's

ability

to

remain

cool.

*WESTERBEKE

recommends

this

service

be

performed

by

an

knowledgeable

mechanic.

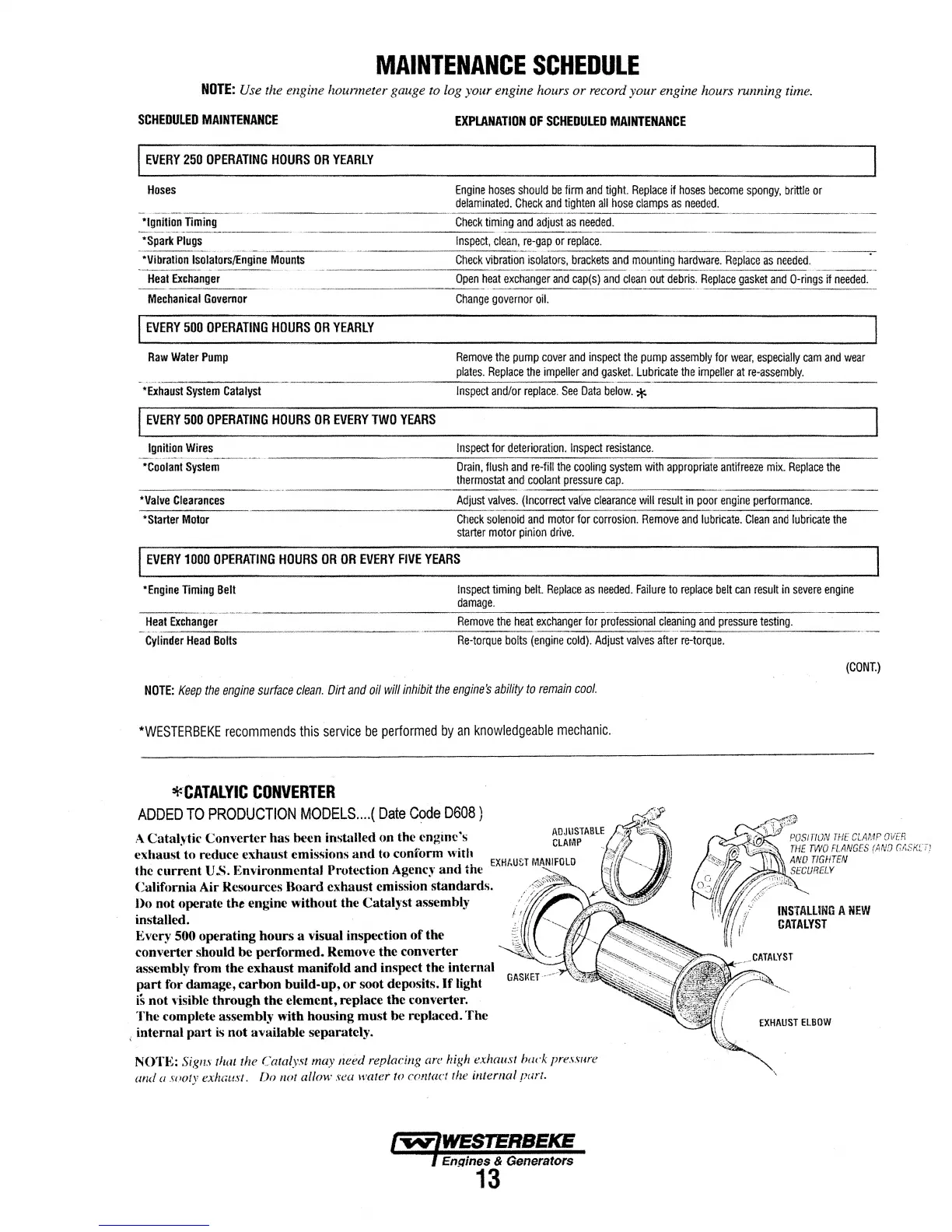

*CATALYIC

CONVERTER

ADDED

TO

PRODUCTION

MODELS

....

(

Date

Code

0608

)

A Catalvtic Converter

has

been installed on the engine's

exhaust

to

reduce exhaust emissions

and

to conform with

EXHl\U~r

MANIFOLO

the

current

U$.

Environmental Protection Agency

and

the "

California

Air

Resources

Board

exhaust emission standards. ,

;-"Ip"'

~>o

not

operate the engine without the Catalyst assembly /

1~

mstaJled.

~.

''-...

Every 500 operating

hours

a visual inspection

of

the

~

converter should be

performed.

Remove

the

converter

'§

- _

assembly from the exhaust manifold

and

inspect the internal

part

for damage,

carbon

build-up,

or

soot deposits.

If

light

is

not

"tisible

through

the element, replace

the

converter.

The

complete assembly with housing

must

be

replaced.

The

, internal

pai1

is

not

available separately.

NOTE: Signs that the

Cataly.~t

may

1ieed

replacing

are

high exhaust back pressure

arul a sooty

exhaust. Do not allow sea water to contact the internal part.

lwlWESTERBEKE

(Engines & Generators

13

(CONT.)

Loading...

Loading...