BATTERY

CHARGING

CIRCUIT

INTEGRAL

CONTROLLER

(l.C.)

The Integral Controller (l.C.) is

an

encapsulated, solid-state

unit that supplies a

DC

charging voltage to the generator's

starting battery

while

the generator

is

opening.

Charging Voltage:

~.o

. 14.0 volts DC

Charging Amperage: 0 • 10.0 amps

DC

A separate

group

of stator

windings

supplies AC

voltage

to

a

bridge rectifier

which

converts the

AC

current

to

supply

the

I.C.

unit.

The

I.C.

unit senses the

needs

of

the starting battery

and supplies a DC charge

when

one is needed

..

If

you

.suspect

that the I.C. unit is

faulty

(that is,

if

the battery's

charge

is

low),

check the

charging

circuit

and

it's components

as

described

in

the

following

steps. Check all connections for

cleanliness and tightness including the ground before

replacing

the

r.c.

unit.

NOTE:

When

the

generator is first

started,

the l

C.

unit

will

produce a low

charging

rate.

'This

charging

rate will

rise

as

the

generator is

operated.

·

The Integral Controller

is

mounted inside the generator

hous-

ing

in the 12:00

position.

There

is

a voltage output

adjustment

on

the

controller that will allow a DC voltage output

adjust-

ment

of±

2

volts.

NOTE:

New

four

wire

controllers eliminate the ballast resistor

circuit

since the ballast resistor's

function

is

now

handled

·

internally.

Whenever

replacing

an

early stylr controller with

the

~wer

four

wire

model,

remove

the ballast resistor

and

its

wiring.

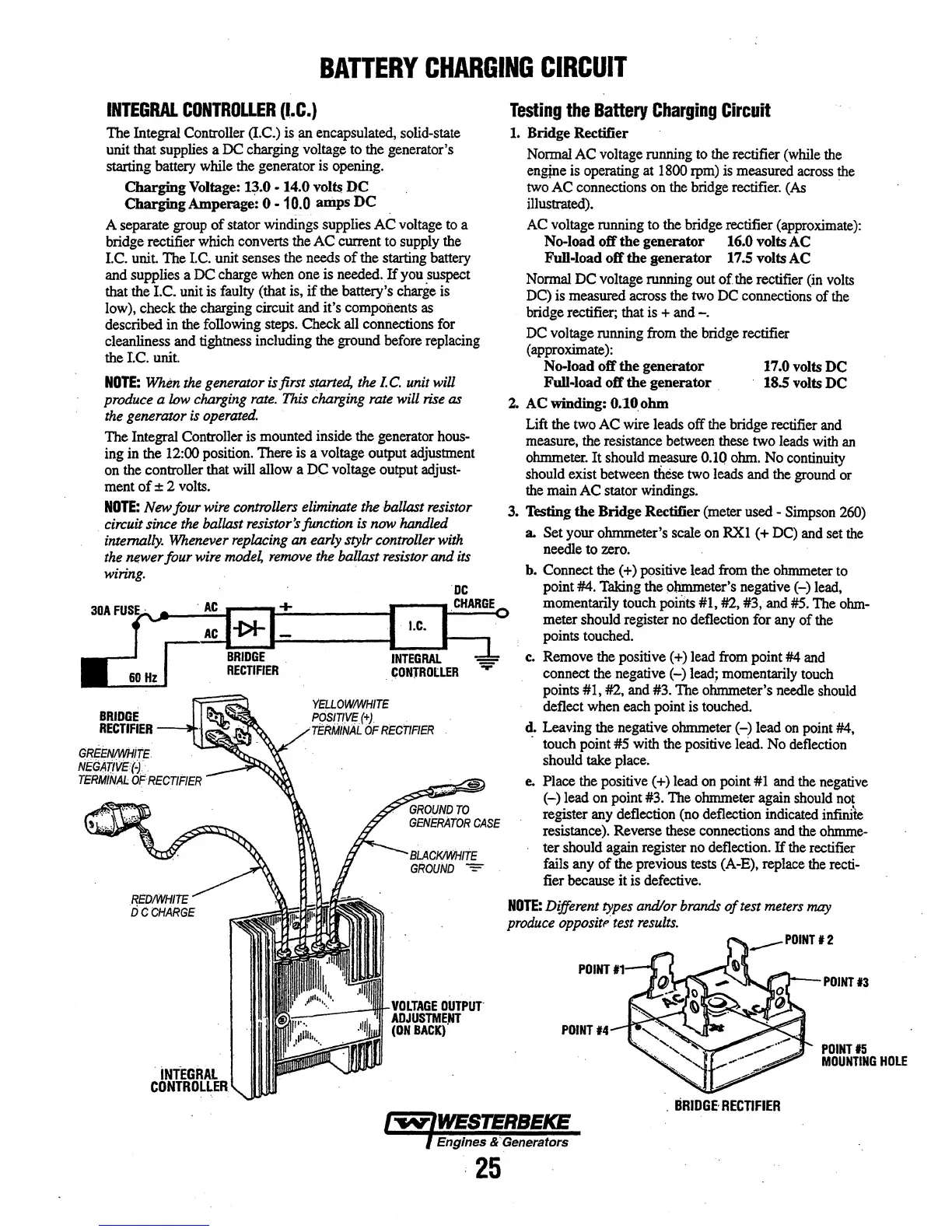

BRIDGE

RECTIFIER

--*~

GREEN!MlitE.

NEGATIVE({.

TERMINAL

oFRECTIFIER

BRIDGE

RECTIFIER

.

iNTEGRAL

CONTROLLER

INTEGRAL

.

CONTROLLER

YELLOW/WHITE

~~W~l°6F

RECTIFIER

Testing

the

Battery

Charging

Circuit

1.

Bridge Rectifier

Normal

AC

voltage

running

to

the

rectifier

(while

the

engine is operating at

1800

zpm)

is

measured

across

the

two

AC

connections

on

the

bridge

rectifier. (As

illustrated).

AC

voltage

running

to

the

bridge

rectifier

(approximate):

No-load off the generator 16.0 volts AC

Full-load off the generator

17.S

volts AC

Normal

DC voltage

running

out of.the rectifier

(in

volts

DC)

is measured across

the

two

DC

connections

of

the

bridge

rectifier; that is + and

-.

DC

voltage running

from

the

bridge

rectifier

(approximate):

No-load off the generator 17.0 volts DC

Full-load off the generator . · 18.5 volts DC

2. AC winding: 0.10.obm

Lift the

two

AC

wire leads off

the

bridge rectifier

and

measure,

the resistance

between

these

two

leads

with

an

ohmmeter.

It

should

measure

0.10

ohm.

No

continuity

should exist

between

these

two

leads

and the

ground

or

the

main

AC stator

windings.

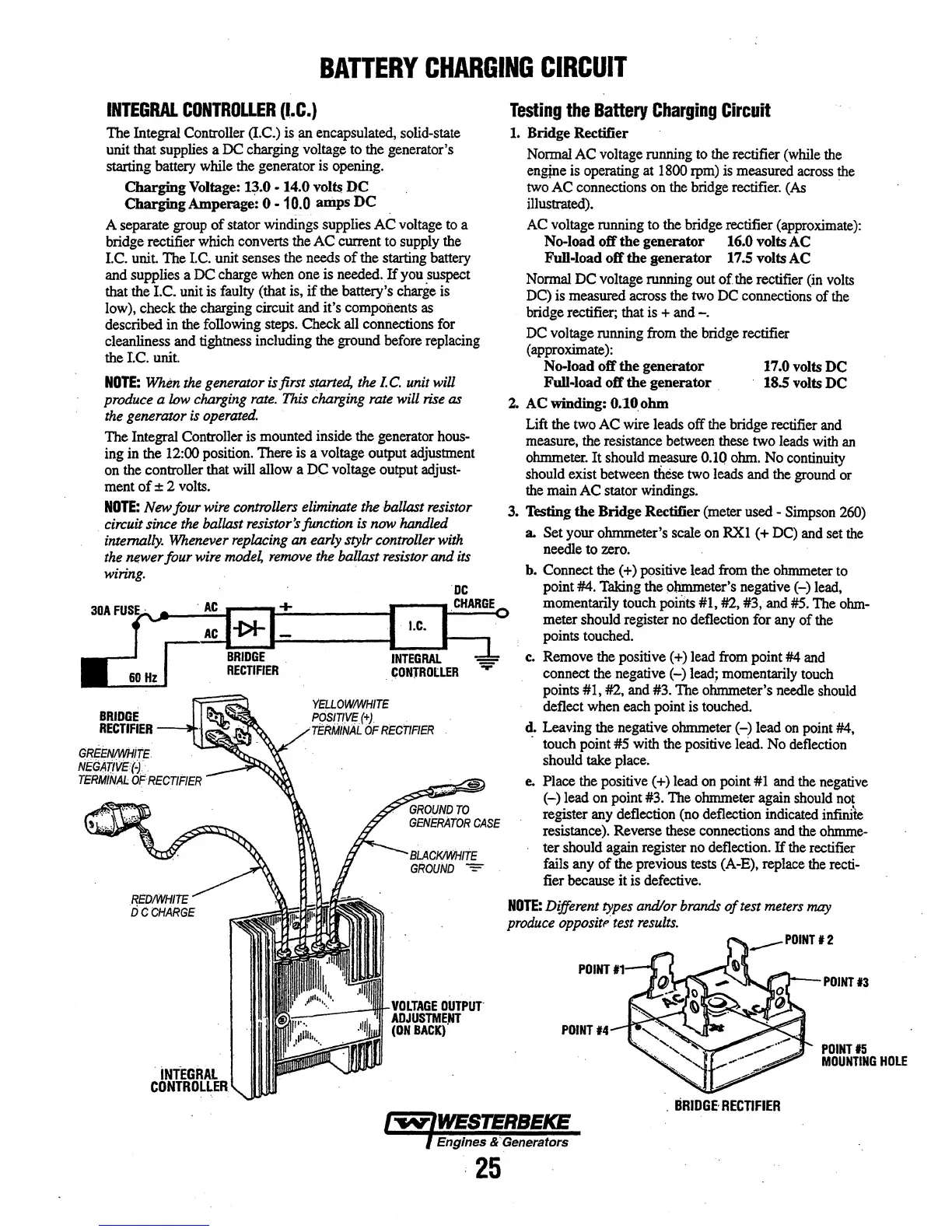

3.

Testing the Bridge Rectifier (meter

used

-

Simpson

260)

a. Set your ohmmeter's scale

on

RXl (+DC)

and

set

the

needle

to

z.ero.

b. Connect

the

(

+)

positive lead

from

the

ohmmeter

to

point

#4.

Taking

the

ob:mmeter's

negative (-)

lead,

momentarily touch

poirits

#1,

#2,

#3,

and

#5. The

ohm-

meter should register

no

deflection for

any

of the

points

touched.

c.

Remove

the

positive ( +) lead

from

point #4

and

connect

the

negative(-)

lead;

momentarily

touch

points

#1,

#2,

and

#3.

The

ohmmeter's

needle

should

deflect

when

each

point

is

touched.

d.

Leaving

the

negative ohmmeter (-) lead

on

point

#4,

·

touch

point

#S

with

the positive

lead.

No

deflection

should take place.

e.

Place

the

positive ( +)

lead

on

point

#1

and

the

negative

(-) lead

on

point #3.

The

ohmmeter

again

should

not

register

any

deflection

{no

deflection

indicated

infinite

resistance). Reverse

these

connections

and

the

ohmme-

ter should

again

register

no

deflection.

If

the

rectifier

fails

any of the previous

tests

(A-E),

replace

the

recti-

fier because it

is

defective.

NOTE:

Different types and/or

brands

of

test

meters

may

produce

oppositf'.

test

results.

POINTl4

.

BRIDGE

RECTIFIER

POINTl3

POINTl5

MOUNTING

HOLE

Engines &·Generators

;

25

Loading...

Loading...