COOLING

SYSTEM

DESCRIPTION

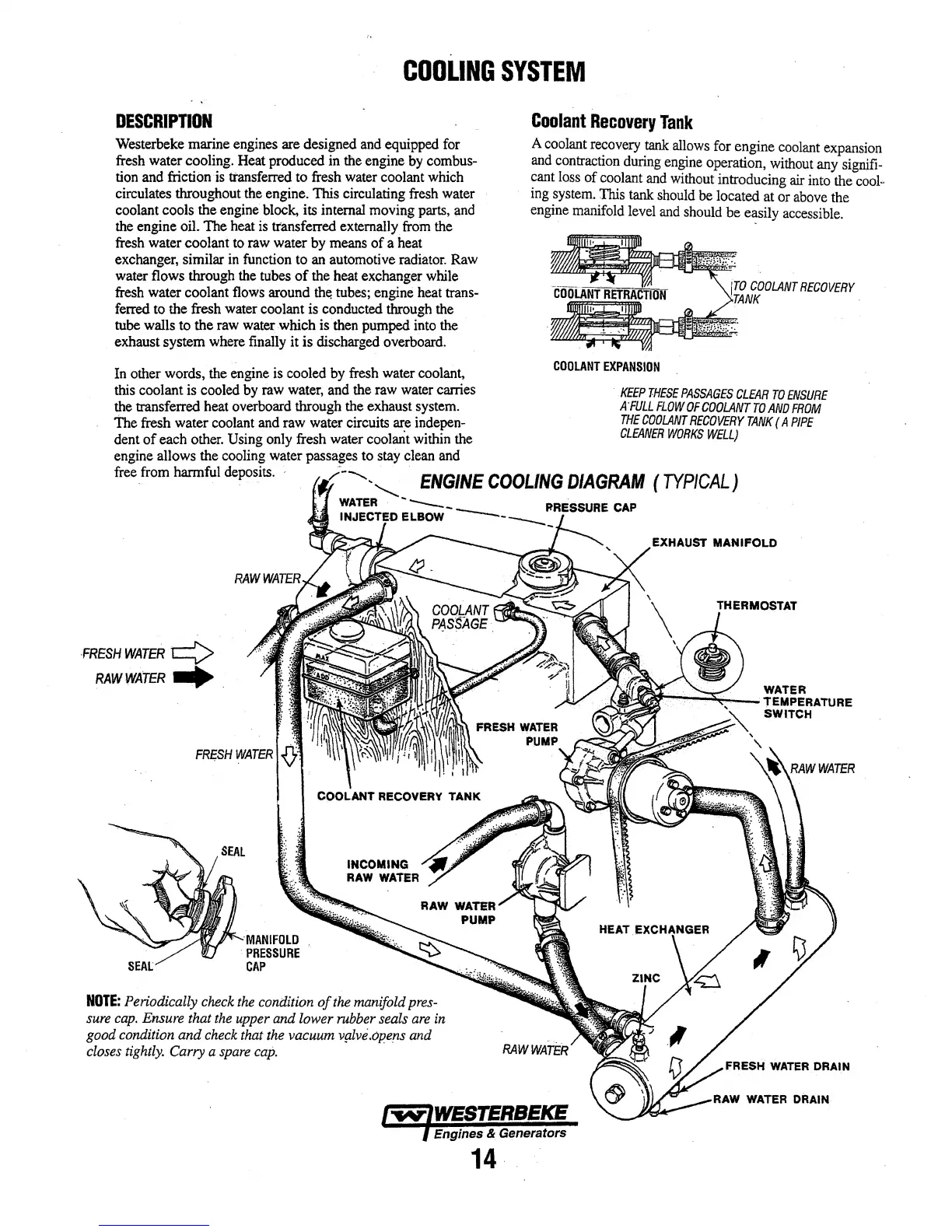

Westerbeke marine engines

are

designed and equipped for

fresh water cooling. Heat produced in the engine by combus-

tion and friction is transferred to fresh water coolant which

circulates throughout the engine. This circulating fresh water

coolant cools

the

engine block, its internal moving parts, and

the engine oil.

The

heat is transferred externally from the

fresh water coolant to raw

water

by means

of

a heat

exchanger, similar in function to an automotive radiator. Raw

water flows through the tubes

of

the heat exchanger while

fresh water coolant flows around

th~

tubes; engine heat trans-

ferred to

the

fresh water coolant is conducted through the

tube walls

to

the

raw water

which

is then pumped into the

exhaust system where finally

it

is

discharged overboard.

In other words, the engine is cooled by fresh water coolant,

this coolant is cooled

by

raw water, and the raw water carries

the transferred heat overboard through the exhaust system.

The

fresh water coolant

and

raw

water circuits are indepen-

dent

of

each

other. Using only fresh water coolant within the

engine allows the cooling water passages to stay clean and

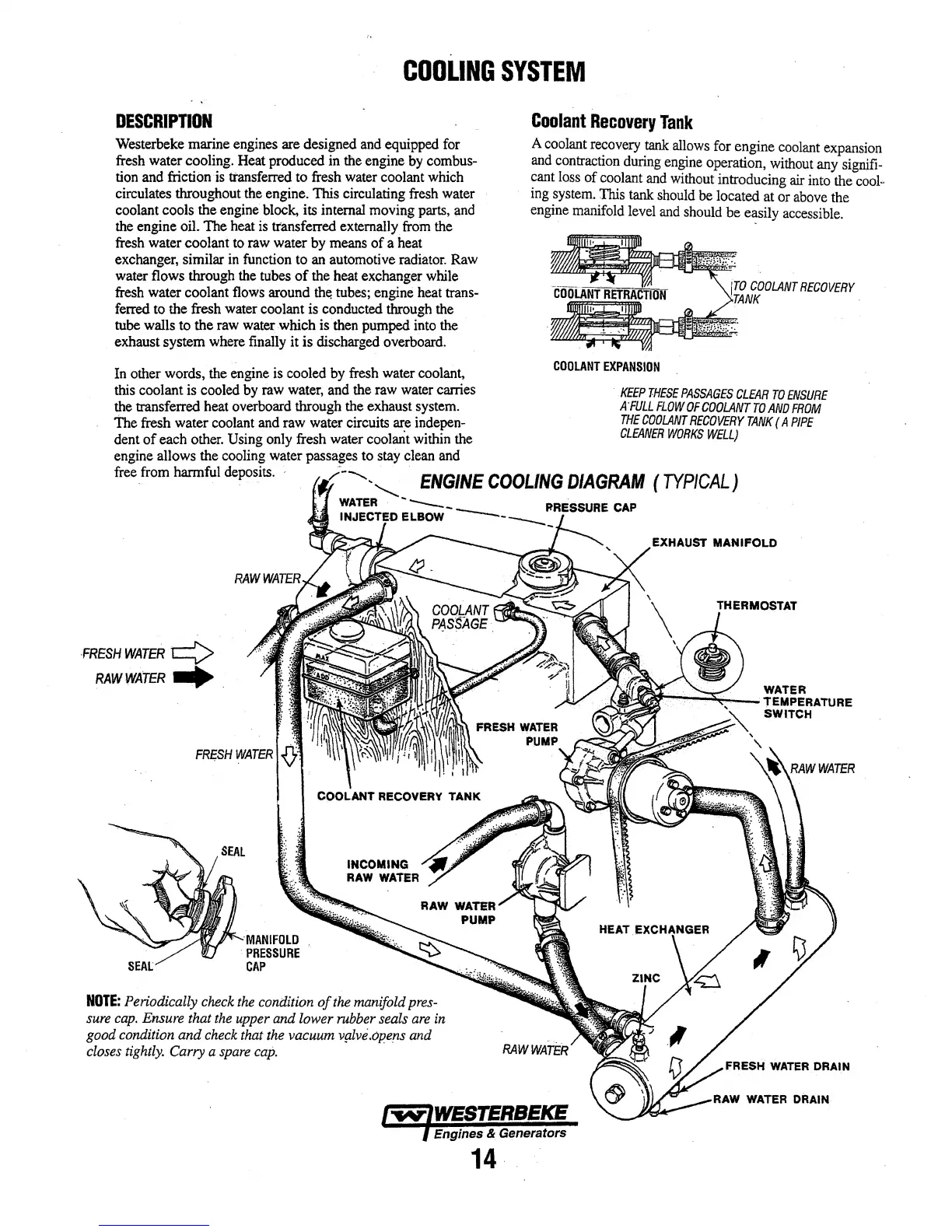

Coolant

Recovery

Tank

A coolant recovery

tank

allows for engine coolant expansion

and contraction during engine operation, without any signifi-

cant loss

of

coolant and without introducing

air

into the cool··

ing system. This tank should

be

located at or above the

engine manifold level and should

be

easily accessible.

jTO

COOLANT

RECOVERY

TANK

·

COOLANT

EXPANSION

KEEP

THESE

PASSAGES

CLEAR

TO

ENSURE

A

'FULL

FLOW

OF

COOLANT

TO

AND

FROM

THE

COOLANT

RECOVERY

TANK

(A

PIPE

CLEANER

WORKS

WELL)

free from harmful deposits. ,,..·--.._'-......_

ENGINE

COOLING

DIAGRAM

(TYPICAL)

WATER

---..

-

--

FIRESSURE

CAP

INJECTED ELBOW

----

FRESH

WATER¢

RAWWATER

....

MANIFOLD

·PRESSURE

CAP

INCOMING

RAW

WATER

NOTE:

Periodically check

the

condition

of

the

manifold pres-

sure

cap.

Ensure that

the

upper and lower rubber seals

are

in

good condition

and

check that the vacuum vplve.opens and

closes tightly. Carry a

spare

cap.

14

RAW

WATER

DRAIN

Loading...

Loading...