en-US Installation and electrical connection

14 WILO SE 2017-03

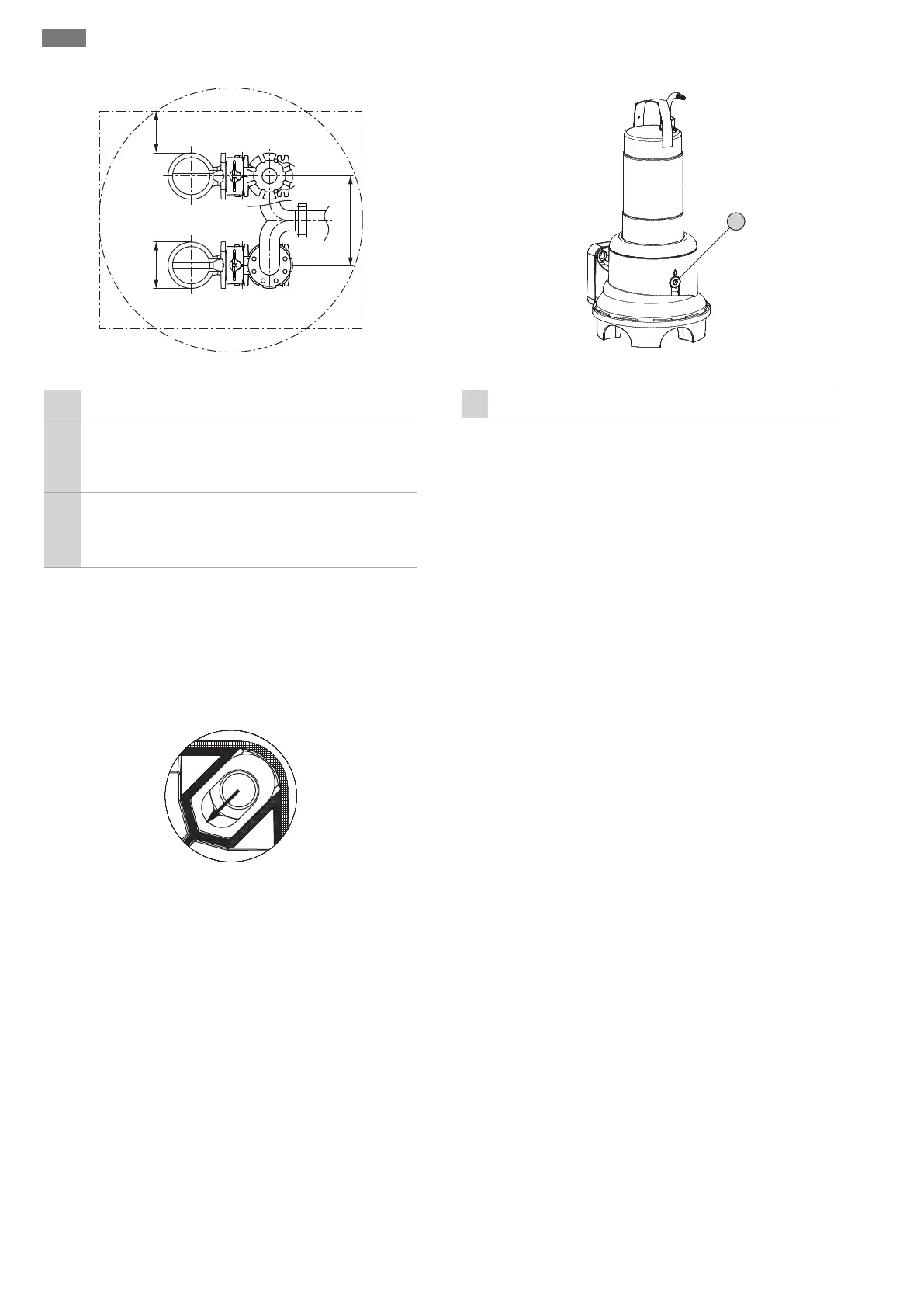

Fig.3: Minimum distances

d Diameter of the hydraulics housing

A

1

Minimum distance from the wall:

- alternating operation: min. 0.3×d

- parallel operation: min. 1×d

A

2

Distance discharge pipes

- alternating operation: min. 1.5×d

- parallel operation: min. 2×d

6.4.2 Instruction for combination flange DN50/65

The Rexa UNIV06... is fitted with a combination flange

DN50/65. The nuts on the combination flange are fac-

tory-set to the flange DN65. To use on a flange DN50,

adjust the nuts on the flange. The flange can be reset

at any time to DN65!

Fig.4: Adjust combination flange

‡ No accessories mounted on flange.

‡ Nut is freely available.

1. Press nut inwards onto the small hole circle using a

screw driver.

▶ Flange connection converted to DN50.

6.4.3 Maintenance work

After a storage period of more than 6months check the

oil in the sealing chamber before installation:

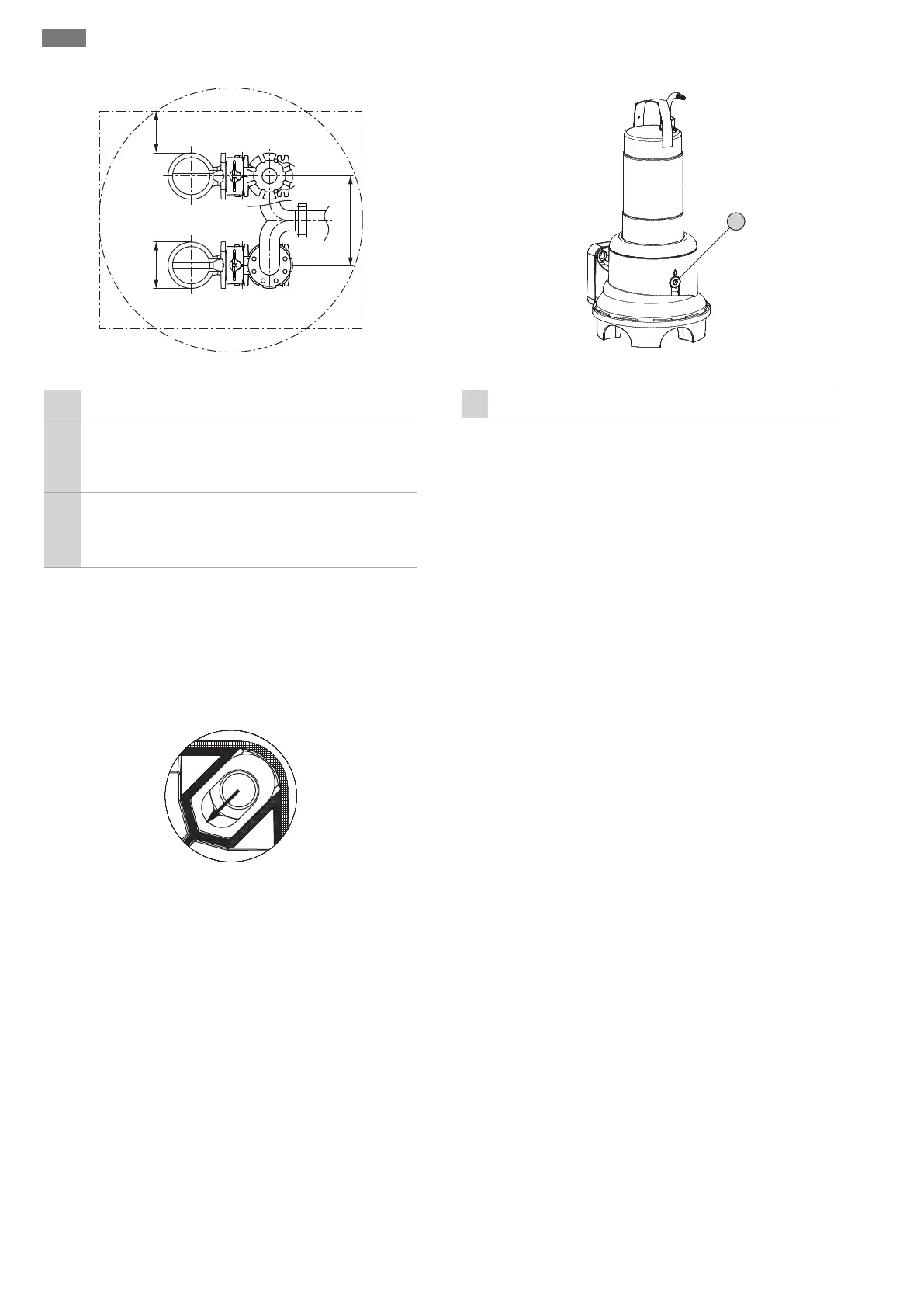

Fig.5: Check oil

1 Sealing chamber screw plug

‡ Pump is not built-in.

‡ Pump is not connected to the power supply.

‡ Protective equipment has been put on!

1. Position the pump horizontally on a firm surface. The

screw plug is facing upwards. WARNING!Danger of

crushing hands. Make sure that the pump cannot fall

over or slip!

2. Unscrew screw plug.

3. Place a suitable tank to collect the operating fluid.

4. Drain operating fluid: Rotate the pump until the hole

points downwards.

5. Check operating fluid:

⇒ When the operating fluid is clear, re-use the oper-

ating fluid.

⇒ If the operating fluid is contaminated (black), pour

in new operating fluid. Dispose of operating fluids

according to the local regulations!

⇒ If there are metal chips in the operating fluid, in-

form customer service!

6. Pour in operating fluid: Rotate the pump until the hole

points upwards. Pour operating fluid into the hole.

⇒ Adhere to the information for operating fluid type

and quantity! When re-using operating fluid, the

quantity must also be checked and adjusted, if

necessary!

7. Clean the screw plug, replace the seal ring, and screw it

back in. Max. tightening torque: 8Nm!

Loading...

Loading...