en-US Decommissioning/removal

22 WILO SE 2017-03

2. Attach lifting equipment to attachment point. CAU-

TION!Never pull on the power supply cable! By doing

this the power supply cable gets damaged!

3. Slowly raise the pump and lift it over the guide pipes

out of the operating space. CAUTION!The power sup-

ply cable can be damaged when lifting! During lifting,

hold the power supply cables slightly taut!

4. Thoroughly clean the pump (see point “Cleaning and

disinfecting”). DANGER!When using the pump in flu-

ids which are dangerous to health, disinfect the

pump!

8.4.2 Portable wet well installation

‡ Pump decommissioned.

1. Disconnect pump from power supply.

2. Roll up the power supply cable and lay over the motor

housing. CAUTION!Never pull on the power supply

cable! By doing this the power supply cable gets

damaged!

3. Loosen the pressure pipe from the discharge port.

4. Attach lifting equipment to attachment points.

5. Lift pump out of the operating space. CAUTION!The

power supply cable can be crushed and damaged

when setting down! When setting down the pump, be

mindful of the power supply cables!

6. Thoroughly clean the pump (see point “Cleaning and

disinfecting”). DANGER!When using the pump in flu-

ids which are dangerous to health, disinfect the

pump!

8.4.3 Clean and disinfect

DANGER

Danger due to fluids which are dangerous to

health!

When the pump is used in fluids which are danger-

ous to health there is a danger to life! Decontami-

nate pump before all further activity! Wear the fol-

lowing protective equipment during cleaning:

• Closed safety goggles

• Breathing mask

• Protective gloves

⇒ The listed equipment is the minimum require-

ment, observe the information from the work

regulations! The operator must ensure that

the personnel have received and read the

work regulations!

‡ Pump removed.

‡ The contaminated cleaning water is fed into the

sewage according to the local regulations.

‡ Disinfectants are available for contaminated pumps.

1. Attach lifting equipment to the attachment point of

the pump.

2. Raise pump to approx. 30cm above the ground.

3. Hose the pump from top to bottom with clear water.

NOTICE!For contaminated pumps corresponding dis-

infectants must be used! Strictly comply with the

manufacturer’s information for use!

4. To clean the impeller and pump interior, guide the wa-

ter jet inside through the discharge port.

5. Flush all dirt residues on the ground into the channel.

6. Allow the pump to dry out.

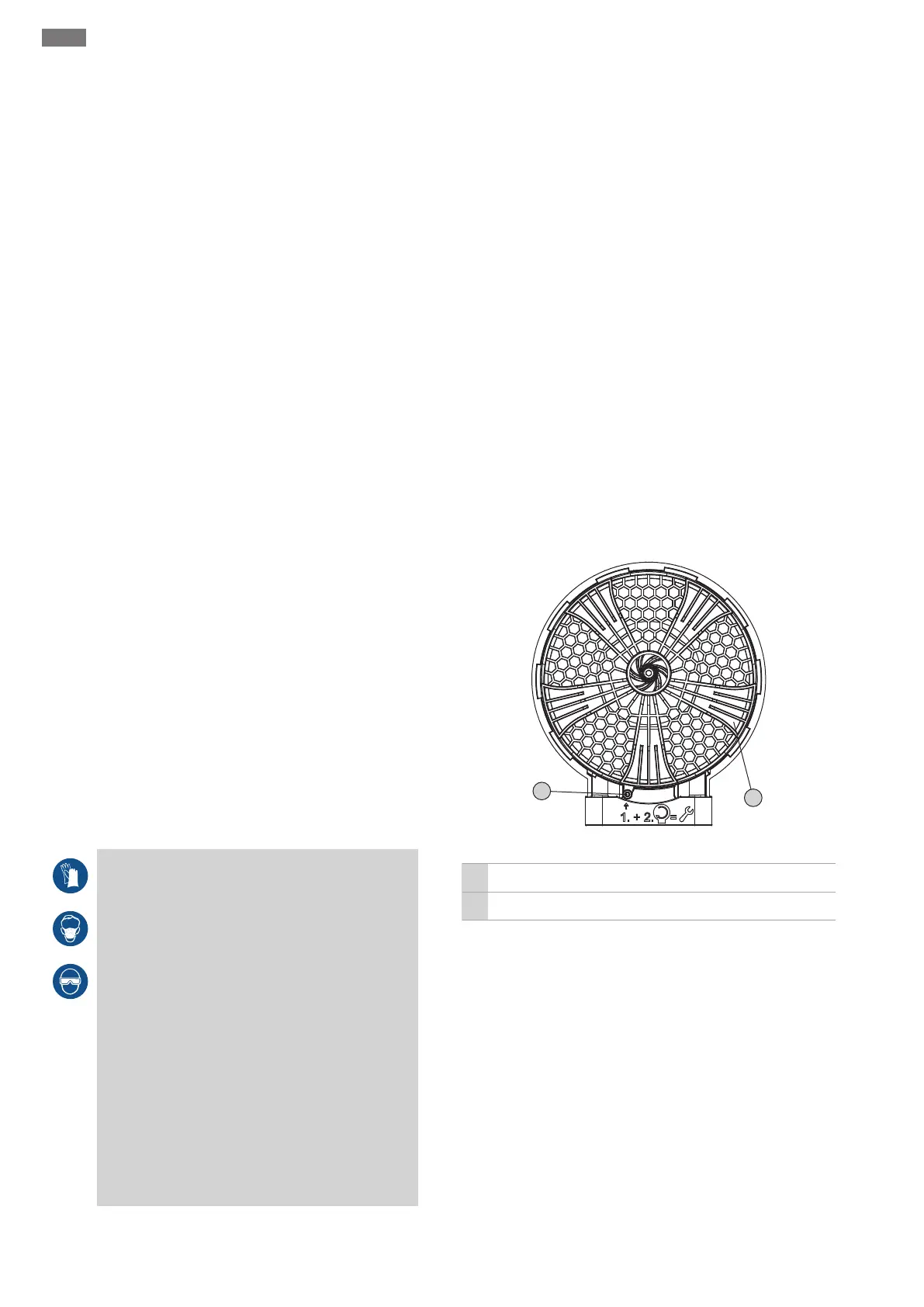

8.4.3.1 Clean the hydraulics interior

For easy cleaning of the hydraulics interior, disassemble

the baseplate of the hydraulics.

Fig.10: Remove baseplate

1 Safety screw

2 Baseplate

1. Position the pump horizontally on a firm surface.

WARNING!Danger of crushing hands. Make sure that

the pump cannot fall over or slip!

2. Unscrew safety screw (hexagon socket 4) of the base-

plate halfway, until the bayonet coupling can be

turned.

3. The baseplate is attached with bayonet coupling. Ro-

tate the baseplate clockwise (right) and remove.

4. Flush out the hydraulics interior with clear water, re-

move solids by hand. WARNING!Sharp edges can form

on the impeller. This can result in the severing of

Loading...

Loading...