Installation and operating instructions WILO Mather and Platt – VT pumps 29

8.7 Alignment of the pumps and its driving units

• When the sole plate is leveled and the satisfactory alignment

is completed, proceed with connection of suction & delivery

piping. Recheck the alignment after piping and run the final

grout beneath the base plate. Allow minimum seven days’

time for curing. Grout mix in the proportion specified earlier

for foundation bolt grouting should be used. It is further

recommended that all hollow pockets in the base plate shall

be filled after curing of earlier grout.

• The following procedures outline recommended practice

given in BS-3170 in 1972 (Appendix A) for checking shaft

alignment. This method is independent of the truth of the

coupling or shaft and is therefore not affected by canted

coupling faces or eccentricity of the outside diameter of the

coupling. Before commencing the alignment, rotate each

shaft independently to check that the bearings run freely and

that the shaft is true to 0.1mm or better. Check that no

damage can be caused when the shaft of the driven unit is

turned. Coupling should be loosely coupled, and the halves

must be free to move relative to each other, otherwise

Indicators can be incorrect. Where, tightly fitting pins gauge

or spring prevent loose coupling, the springs or pins should

be removed, a line scribed across both half couplings and

readings taken only when the two marks are aligned.

Angular alignment

• After isolating the driven unit from its power supply, clamp

two dial indicators are dramatically opposite points on one

half coupling or to the shaft behind it with the plunger resting

on the back of the other half coupling as shown in (Fig. 9 Pg.

No. 7) Rotate the coupling unit the gauges are in line

vertically and set the dial to read zero. Rotate the coupling by

180° and record the readings on each gauge. The readings

should be identical, though not necessarily zero. Either

positive or negative readings are acceptable provided they

are equally positive or negative. Adjust the position of one of

the units if necessary. Rotate the couplings unit the gauges

are in the line horizontally and adjust the dial to zero. Repeat

the operation outlined above by rotating the coupling by

180°. In case where fitment of dial gauge is not feasible check

gap between two coupling halves with the help of filler

gauge.

Radial alignment

• Clamp a dial gauge on one of the couplings or to the shaft as

shown in (figure 9 Pg. No. 7), with the plunger resting on the

rim of the other half coupling. Set the dial zero. Rotate the

coupling and note the reading at each quarter revolution. Any

variation in the readings indicates the deviation from

alignment and the position of one of the units must be

adjusted until the readings at each quarter revolution are

identical or within the tolerances given below.

CAUTION! Risk of material damage!

Oil level in reservoir to be checked and maintained

regularly to prevent damage to line shaft and bowl bush

bearing.

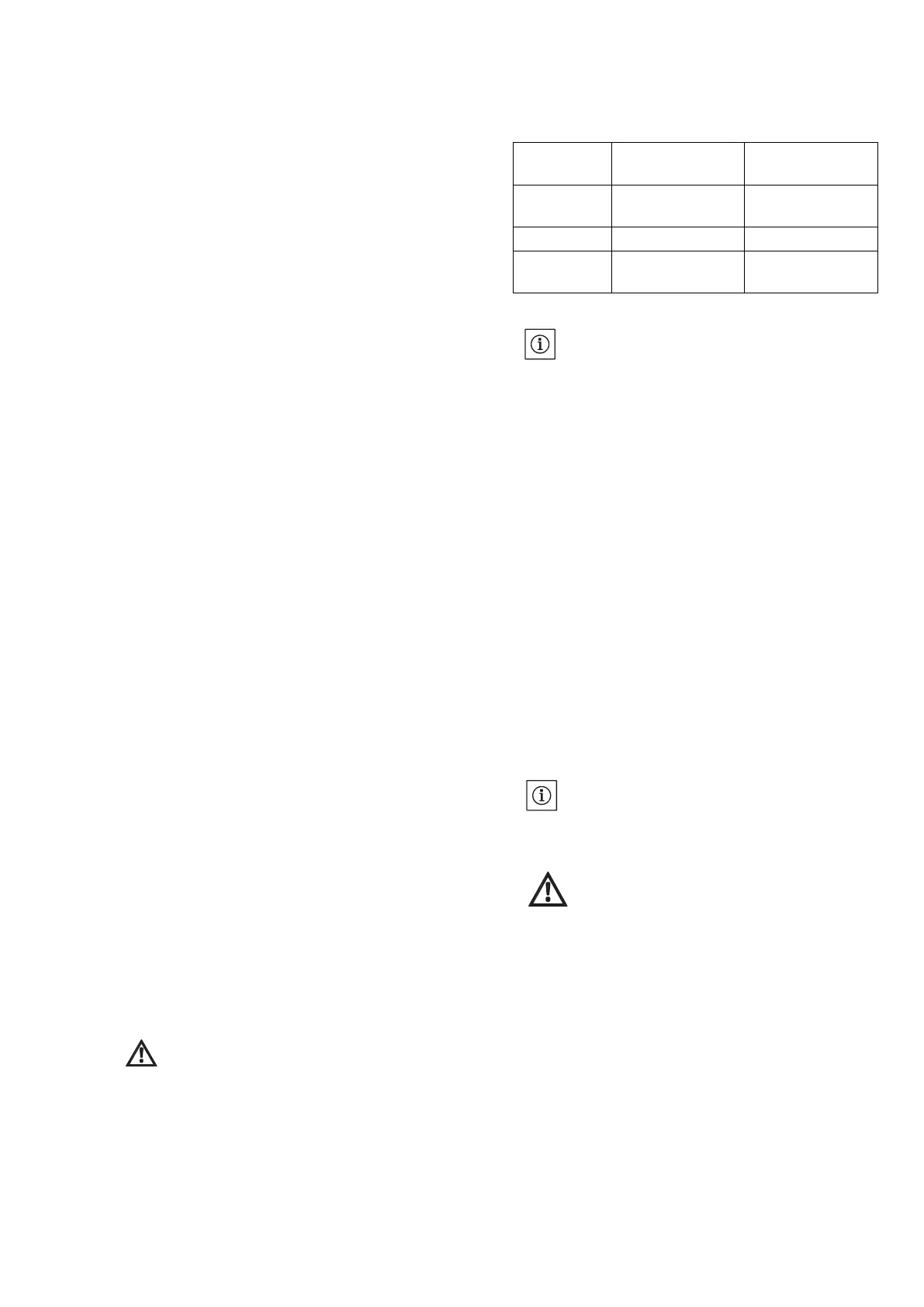

Alignment Tolerances:

TIR- Total Indicated Reading

NOTE:

All the alignments (angular as well as radial) have to be

carried out by using 3 dial indicators simultaneous

8.8 Forced water and oil lubricated pump pre checks

• In case of forced water lubricated pump start the booster

pumps initially to fill in the shaft tubes prior of starting the main

pumps. Check the regulated pressure at both shaft tube and

thrust bearing cooling inlet end. Suitable throttling should be

carried out before providing the supply for bearing cooling.

• Potable or fresh water should be used. If dirty water or raw

water from pump delivery is to be used special self-cleaning

strainers and pressure filters should be employed. A sufficient

size overhead tank should be selected for supplying of potable

water. Level switches should be employed to prevent water in

tank from falling below low level, thus preventing the system

from breakdown.

• In case of oil lubricated pumps, oil should be filled till top of the

shaft tube priorly before starting of main water pumps. A

reservoir of suitable size is provided which should be mounted

firmly to motor stool with the help of bracket. Oil flow to shaft

tube and level in reservoir is regulated with the help of an

automatic solenoid valve. Care to taken to only use bronze

bearing bushes in oil lubricated pumps. (Refer Fig. 21, Pg. No.

14)

NOTE:

Always refer forced water schematic provided by pump

manufacturer. (Fig 22 Pg. No. 14)

CAUTION! Risk

of

material

damage!

Oil level in reservoir to be checked and maintained

regularly to prevent damage to line shaft and bowl bush

bearing.

Loading...

Loading...