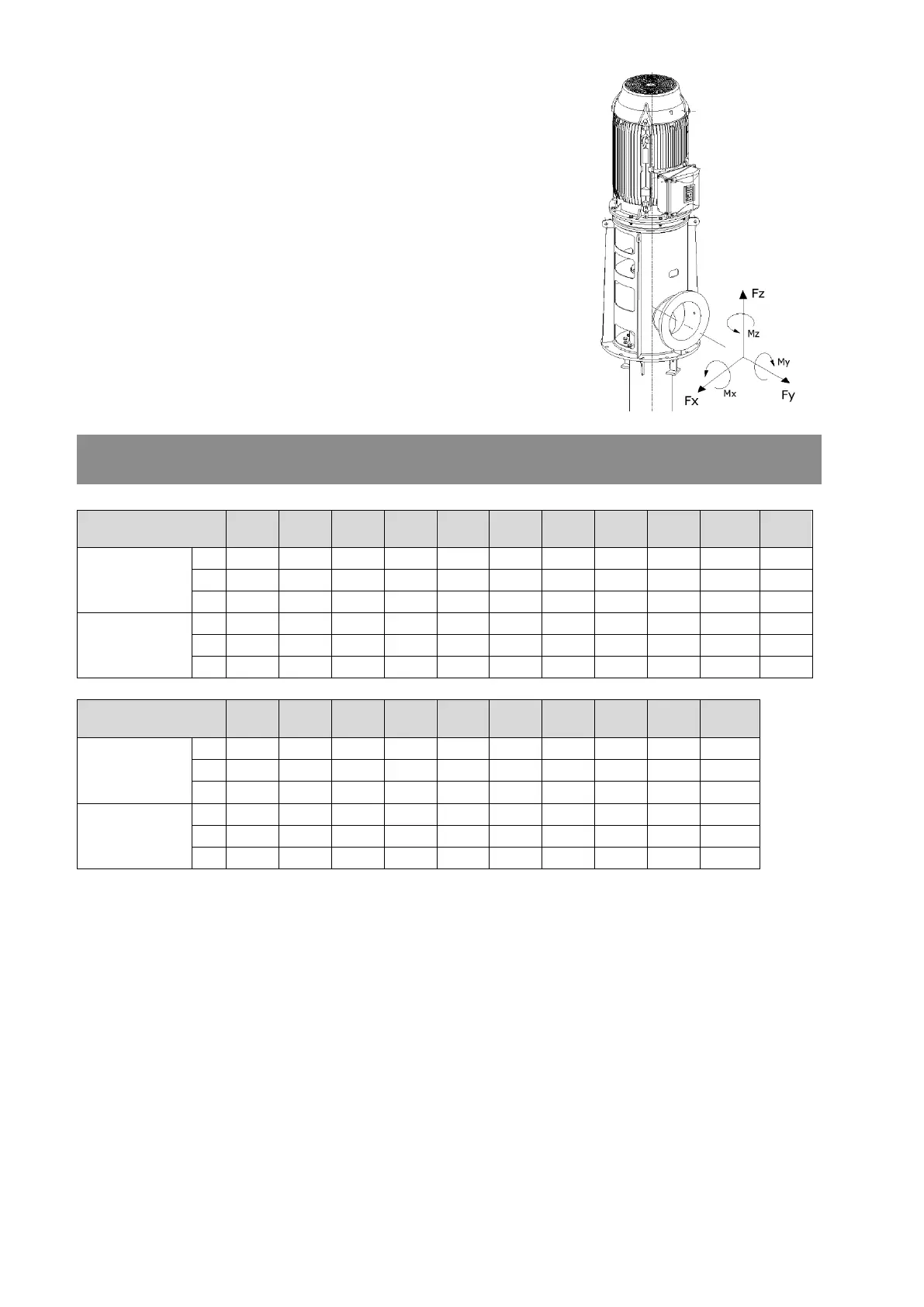

8.9 Pipe work

No stress must be imposed on the pump on delivery side by the pipe

work; neither by the weight of the pipes nor by the tightening of badly

fitting pipes (Refer Fig: 5). All pipe worked attached to the pump must

be fully supported and the mating faces of the pipe flanges must be

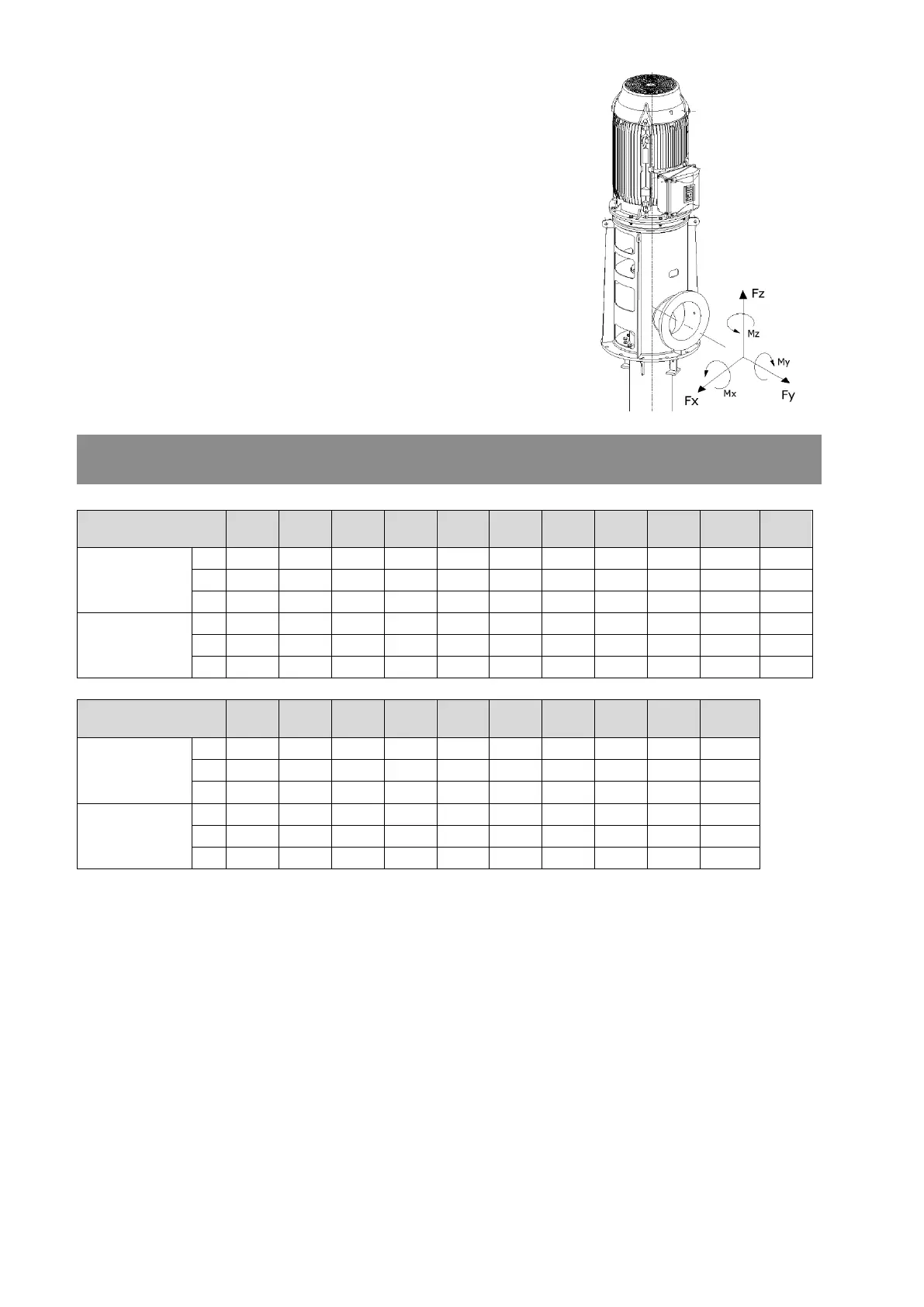

parallel and all bolt holes coinciding with each other. (See table of

maximum forces on flanges) It is important; therefore, that alignment

of the pump and motor should be rechecked after the pipes are finally

fitted. Resetting or supporting the pipes must correct any deviation in

the alignment.

Loading...

Loading...