Marine Installation Manual 2022-03 4-25

4 Ancillary Systems

4.4 Lubricating oil systems

X62DF-S2.0

Full-flow filter

The drain from the filter is to be sized and fitted to allow free flow into the lubri-

cating oil drain tank.

The output required for the main lubricating oil pump to ‘back-flush’ the filter

without interrupting the flow is to be taken into account when estimating the

pump capacity (see Lubricating oil pump, 4-24).

Booster pump for

crosshead lubrication

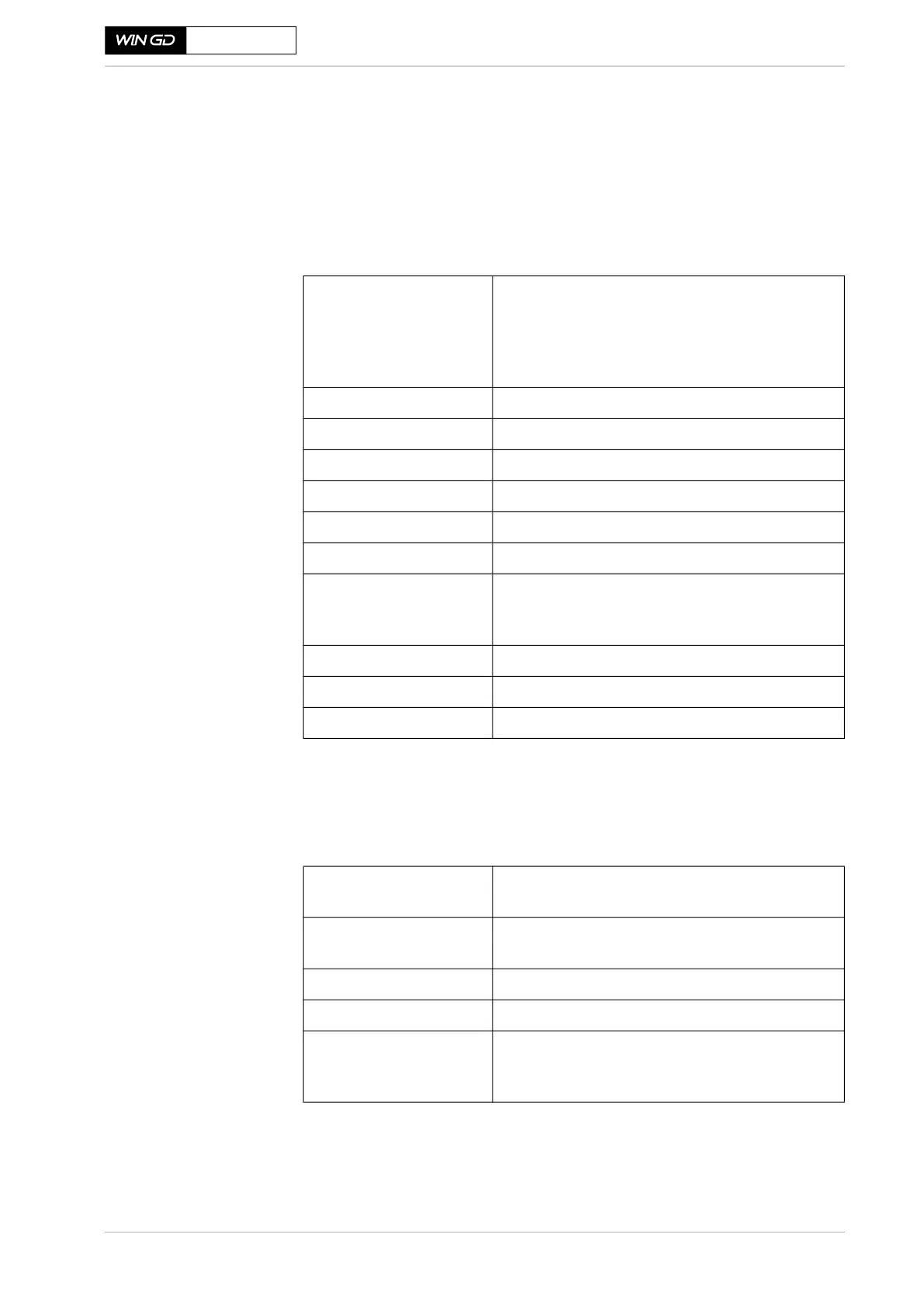

Type

a)

a) Optional: changeover duplex filter designed for in-service cleaning, with differential pressure gauge

and high-differential pressure alarm contacts

Automatic back-flushing filter with differential pressure

gauge and high-differential pressure alarm contacts.

Designed to clean itself automatically using reverse flow

or compressed air techniques.

Back-flushing oil treatment by sludge checker.

Oil flow Refer to GTD.

Working viscosity 95 cSt, at working temperature

Working pressure 6bar

Test pressure Specified by classification society

Diff. pressure, clean filter Max. 0.2 bar

Diff. pressure, dirty filter Max. 0.6 bar

Diff. pressure, alarm Max. 0.8bar

Note: Real operational settings could be less according to

filter maker’s recommendation.

Mesh size Sphere passing max. 0.035 mm

Filter material Stainless steel mesh

Filter inserts bursting press. Max. 3 bar differential across filter

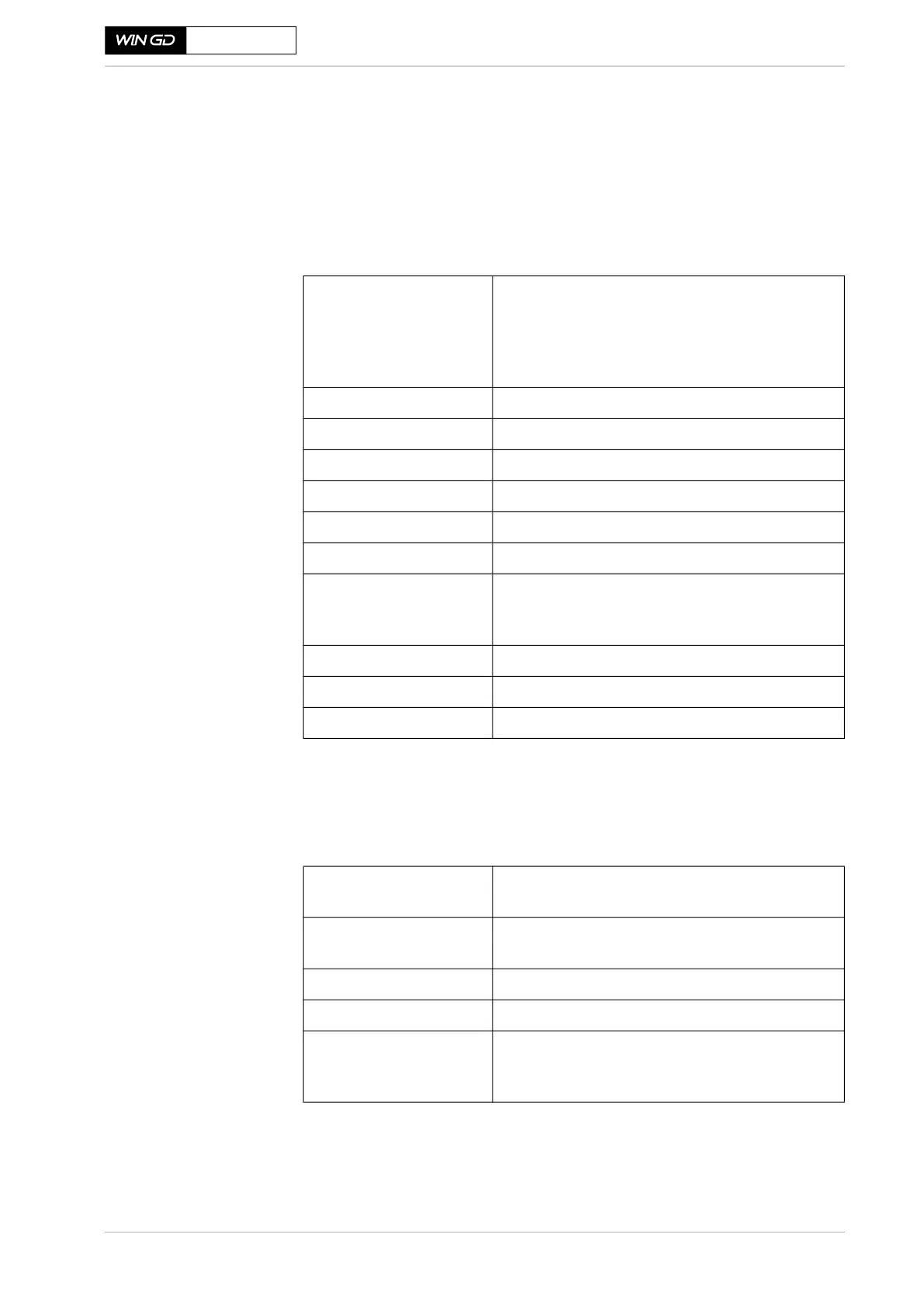

Type Positive displacement screw or gear types with built-in

safety valves

Capacity According to GTD: The flow rate is to be within a tolerance

of 0 to 10 % of the GTD value.

Delivery head Refer to GTD.

Working temperature Approx. 45 °C

Oil type SAE 30, 95 cSt at working temperature; when sizing the

pump motor the maximum viscosity to be allowed for is

400cSt.

Loading...

Loading...