Marine Installation Manual 2022-03 4-44

4 Ancillary Systems

4.5 Fuel gas system

X62DF-S2.0

Free-standing –

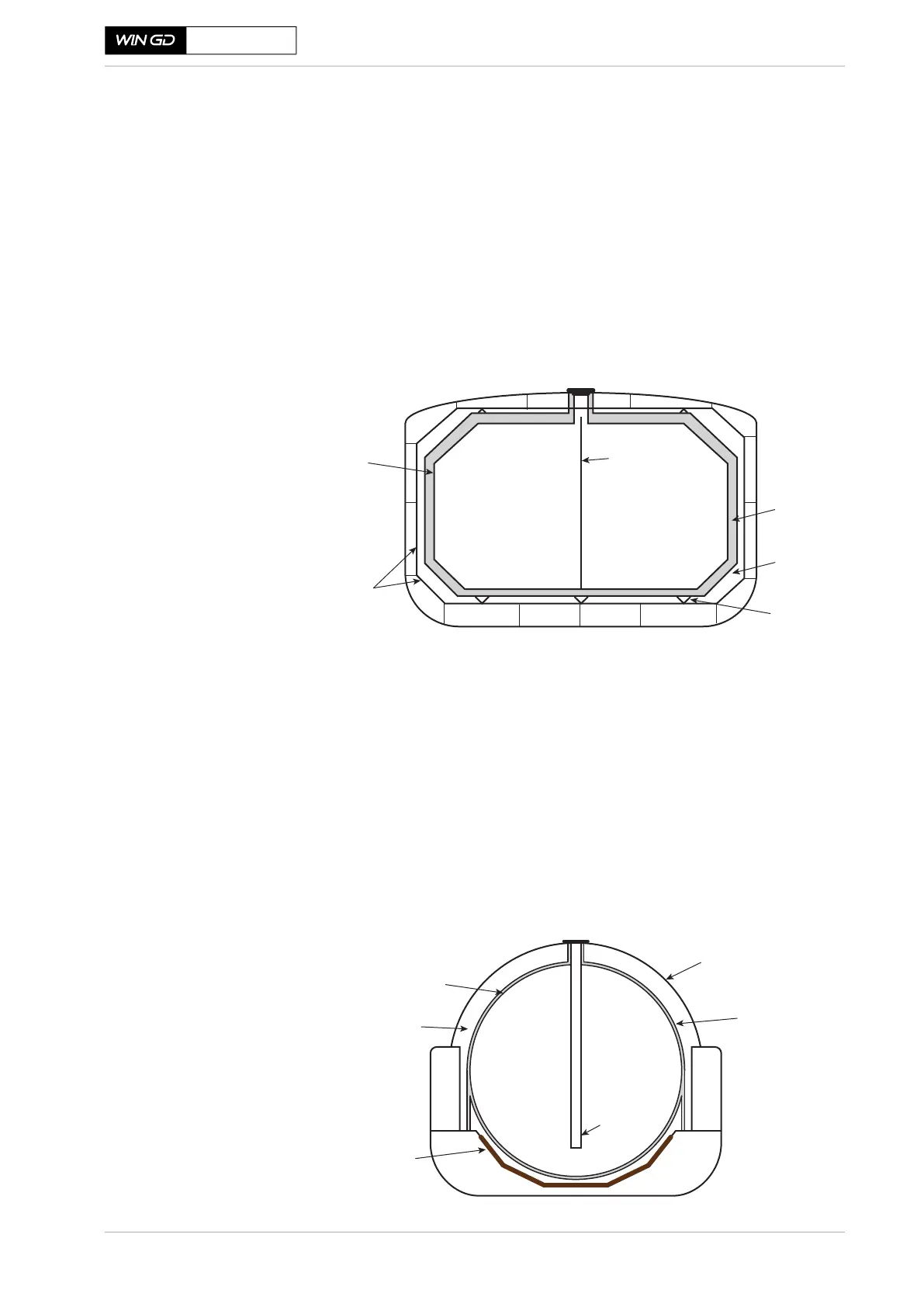

Type A tank

As specified by the IGC Codes, the Type A tank must have a second barrier to

withhold leaks. Often the ship hull is used as this second layer, so to maximise

volume efficiency, the tank is designed in a prismatic shape to best fit inside the

vessels hull. Between the tank wall and secondary barrier is a solid insulation

layer and an air-gap layer. This reduces the thermal impact on the LNG from the

environment, therefore reducing the BOG. This gap also allows for a given ex-

pansion of the tank wall, which is a result of the Type A tank design. The tank

adjusts to the gas pressure due to its flexible structure. Therefore, it is very impor-

tant to control the pressure increase, which must remain within a very limited

pressure range (defined as non-pressurised tank), as otherwise structural dam-

ages would occur.

Figure 4-26 Section view of a free-standing Type A tank

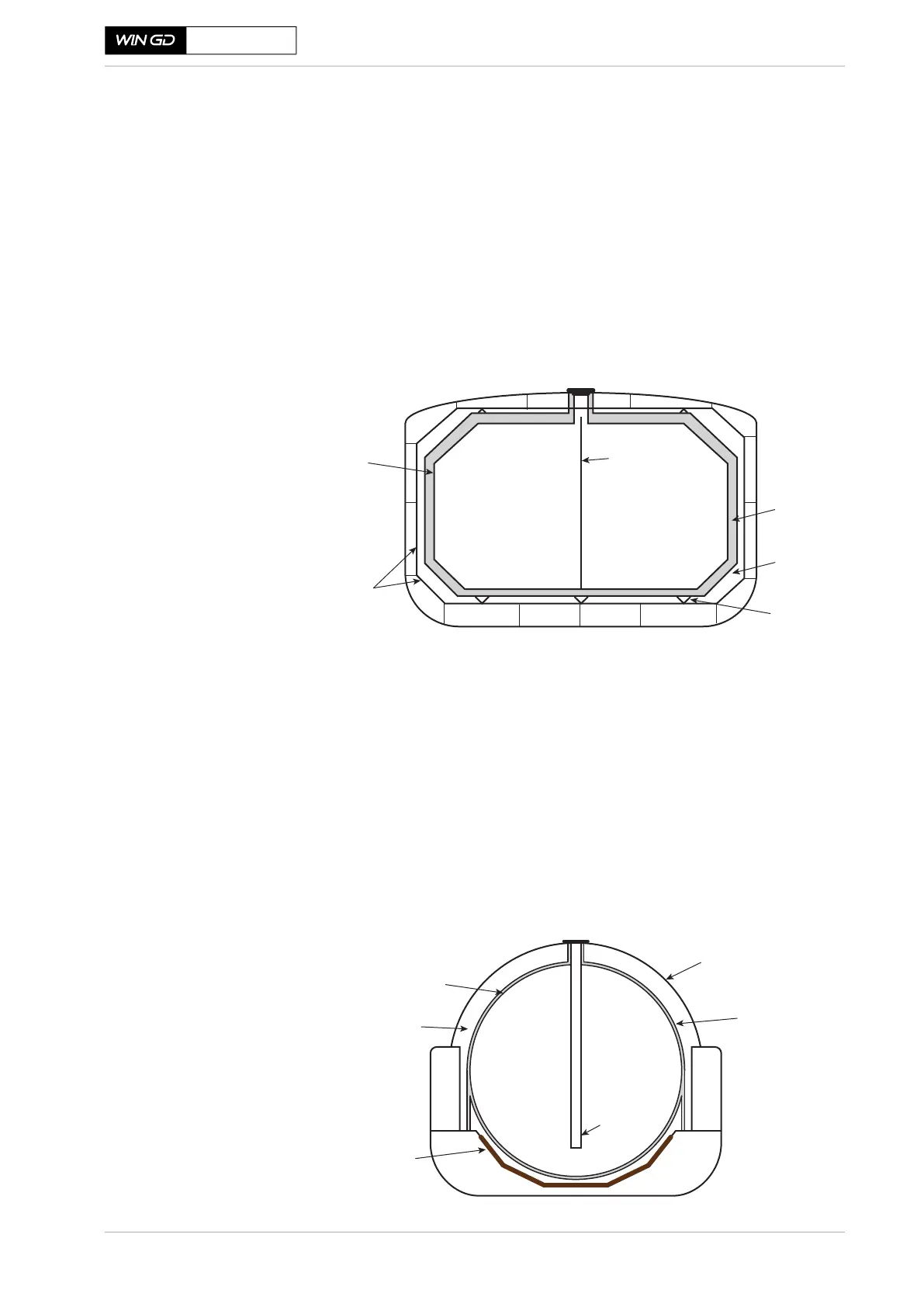

Free-standing –

Type B tank

Same as the Type A tank, the Type B tank is also designed to be non-pressurised

and will respond to pressure increase by expansion. Consequently, it is also as

important to control the pressure increase. The Type B tank design is based on a

fail-safe concept. From crack monitoring and analysis, the ‘Leak before Failure’

approach of this design means that fatigue is progressive and not catastrophic.

Therefore, it is only necessary to have a partial secondary barrier to hold the cal-

culated maximum leakage. In the past, the Type B tank, referred to as the Moss

type (see Figure 4-27), was spherical. This curve-designed shape supports the

even distribution of stress across the tank walls. Nowadays however, the Type B

tank (same as the Type A tank) is also available in a prismatic shape, having a

partial secondary barrier.

Figure 4-27 Section view of a free-standing Type B tank of moss design

SM-0741

Primary

barrier

Secondary

barrier

Insulation

Bulkhead

Inspection

space

Support

SM-0742

Primary

barrier

Drip-tray for

detection leakage

External

insulation

Weather protective

cover

Support tube

for access

Air-gap

Loading...

Loading...