Marine Installation Manual 2022-03 4-15

4 Ancillary Systems

4.3 Cooling water system

X62DF-S2.0

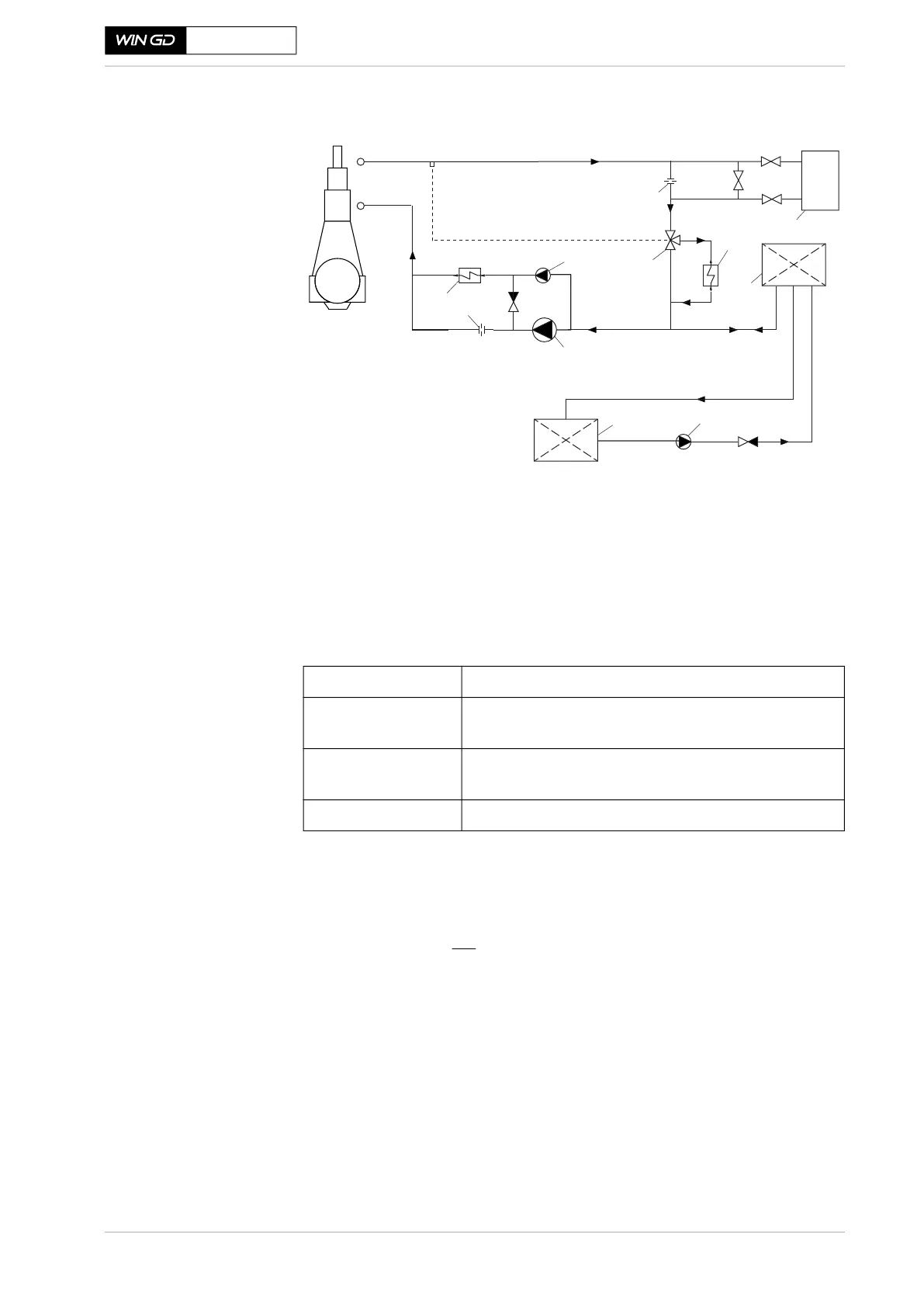

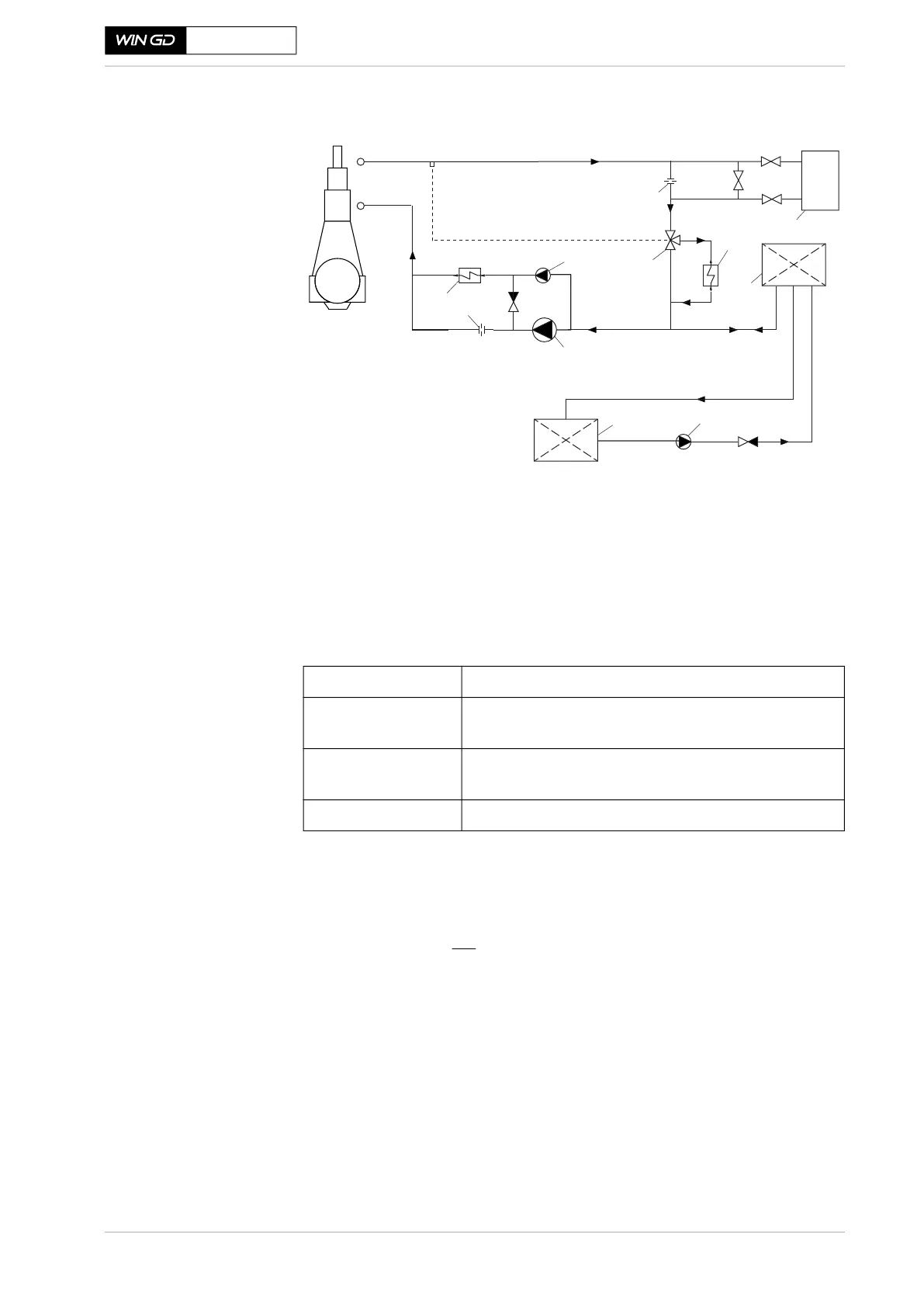

Figure 4-11 HT cooling water circuit

High-temperature circuit components

HT cooling water pump

SM-0321

Main

Engine

3

9

2

1

6

6

8

7

10

4

5

1 HT Pumps

2 Pre-heater pump (optional)

3 Pre-heater for ME

4 HT Cooler (HTC)

5 Automatic temp. control valve

6 Throttling disc

7 Freshwater generator

8 HT Circuit buffer unit

9 Buffer unit supply pump

10 CW feed & drain tank

Pump type Centrifugal, preferably with a steep head curve

a)

a) As a guide, the minimum advisable curve steepness can be defined as follows:

For a pressure increase from 100 to 107 %, the pump capacity should not decrease by more than

10 %.

Pump capacity According to GTD: The flow capacity is to be within a tolerance

of - 10 to +20% of the GTD value

Delivery head

b)

b) The pump delivery head (p

p

) will be:

[bar]

where:

p

ei

= pressure at engine inlet [bar]

p

st

= static pressure* at pump inlet [bar]

Δ

p = pressure losses over piping between pump outlet and engine inlet [bar]

h = height difference between pump outlet and engine inlet [m]

* If an expansion tank is used, p

st

equals the static pressure head from the change in height between

expansion tank and pump inlet.

If a buffer unit is used, p

st

equals the buffer unit pressure plus the pressure head from the change

in height between buffer unit and pump inlet.

The pressure (p

ei

) at engine inlet must be 3.0-5.0bar(g).

To be determined according to the total pressure losses (resist-

ance) of the actual piping installation arrangement

Working temperature 95 °C

Loading...

Loading...