Marine Installation Manual 2022-03 4-77

4 Ancillary Systems

4.7 Fuel oil system

X62DF-S2.0

Option 2

Filter installation in the booster circuit:

The maximum 10 m abs. filter is installed in the booster circuit close to engine

inlet. The filter needs to be laid out for a maximum working temperature of

150°C.

Advantage and disadvantage of this filter position:

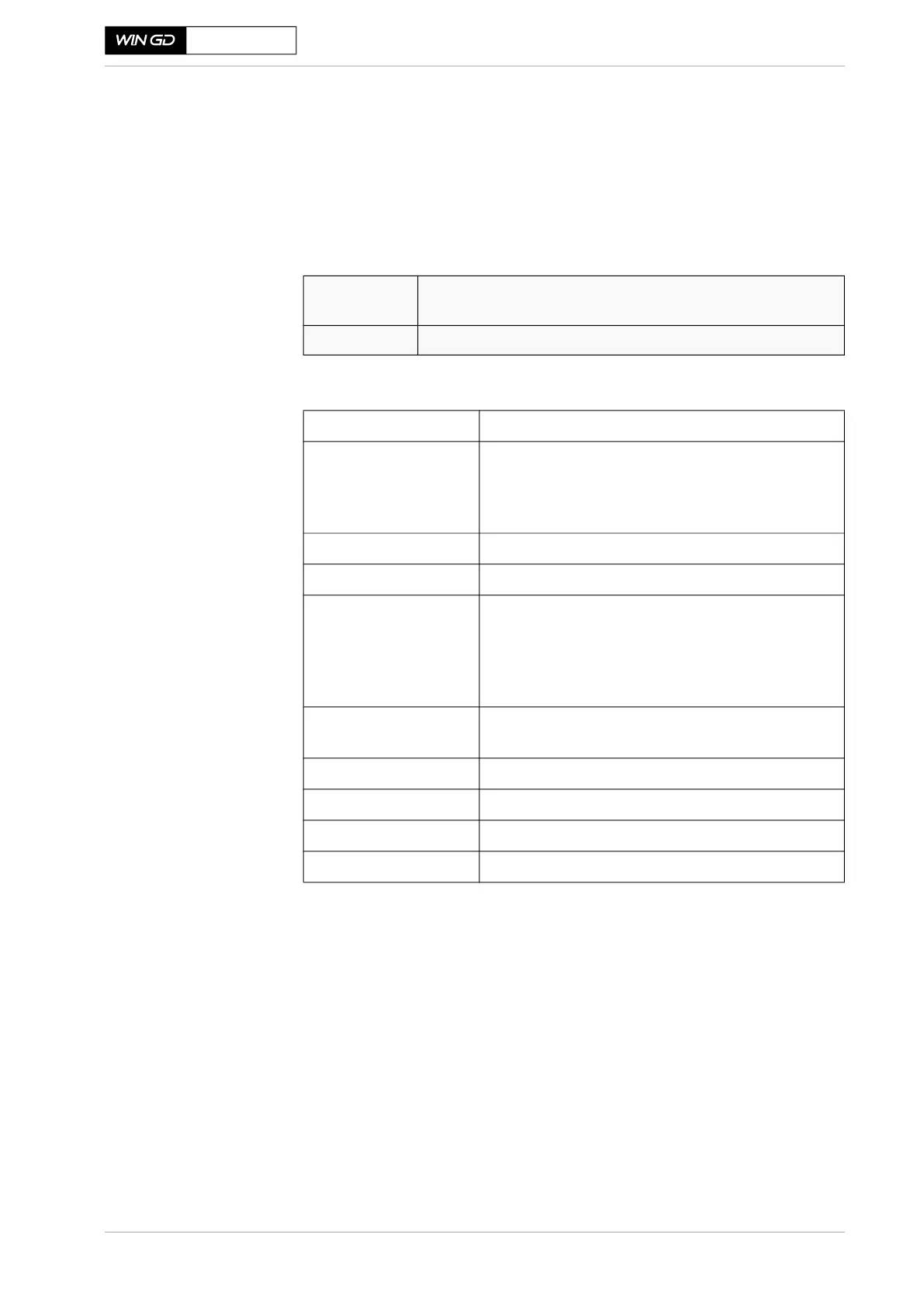

Table 4-12 Specification of automatic self-cleaning filter in booster system

Advantage Optimum engine protection from fuel oil catfines and other abrasive

particles from system wear

Disadvantage Booster pump is not ideally protected against catfines

Working viscosity 10-20 cSt required for HFO (13-17 cSt recommended)

Flow rate According to GTD. The capacities cover the needs of the

engine only. If a filter of automatic back-flushing type is in-

stalled, the feed and booster pump capacities must be in-

creased by the quantity needed for back-flushing of the filter.

Service pressure Max. 12 bar at filter inlet

Test pressure Specified by classification society

Permitted differential press.

at 17 and 20 cSt

— clean filter: max. 0.2 bar

— dirty filter: max. 0.6 bar

— alarm setting: max. 0.8bar

Note: Real operational settings could be less according to

filter maker’s recommendation.

Minimum bursting press.

of filter insert

Max. 3 bar differential across filter

Mesh size Max. 10 m abs.

Mesh size bypass filter Max. 25 m abs.

Filter insert material Stainless steel mesh (CrNiMo)

Working temperature Up to 150°C

Loading...

Loading...