22 3064810_201804

11.Installation

Heatingcircuit

Werecommendinstallingamaintenancevalveinboththeheatingowandheatingreturn–angleddesignforconcealedinstalla-

tion, straight design for surface mounting.

Thereturnlinetotheappliancemusthaveadirttrap.Asludgeseparatorwithmagnetiteseparatorshouldbe

usedtoprotecttheapplianceandthehighefciencypumpfromdirt/sludgeandmagnetite.

Depositsintheheatexchangermayleadtoboilingnoise,adropinperformanceorfaultsintheappliance.

Please

note

Fig:

Angle maintenance valve, with

BDF valve (accessories)

Fig:

Angle maintenance valve with

connection for safety valve, with

BDF valve (accessories)

Fig:

Straight-through maintenance

valve, with BDF valve (acces-

sories)

Fig:

Straight-through maintenance

valve with connection for safety

valve, with BDF valve (acces-

sories)

Heatingcircuitsafetyvalve

Install the safety valve marked "H", max. 3 bar.

Fig: Heating circuit safety valve (accessory)

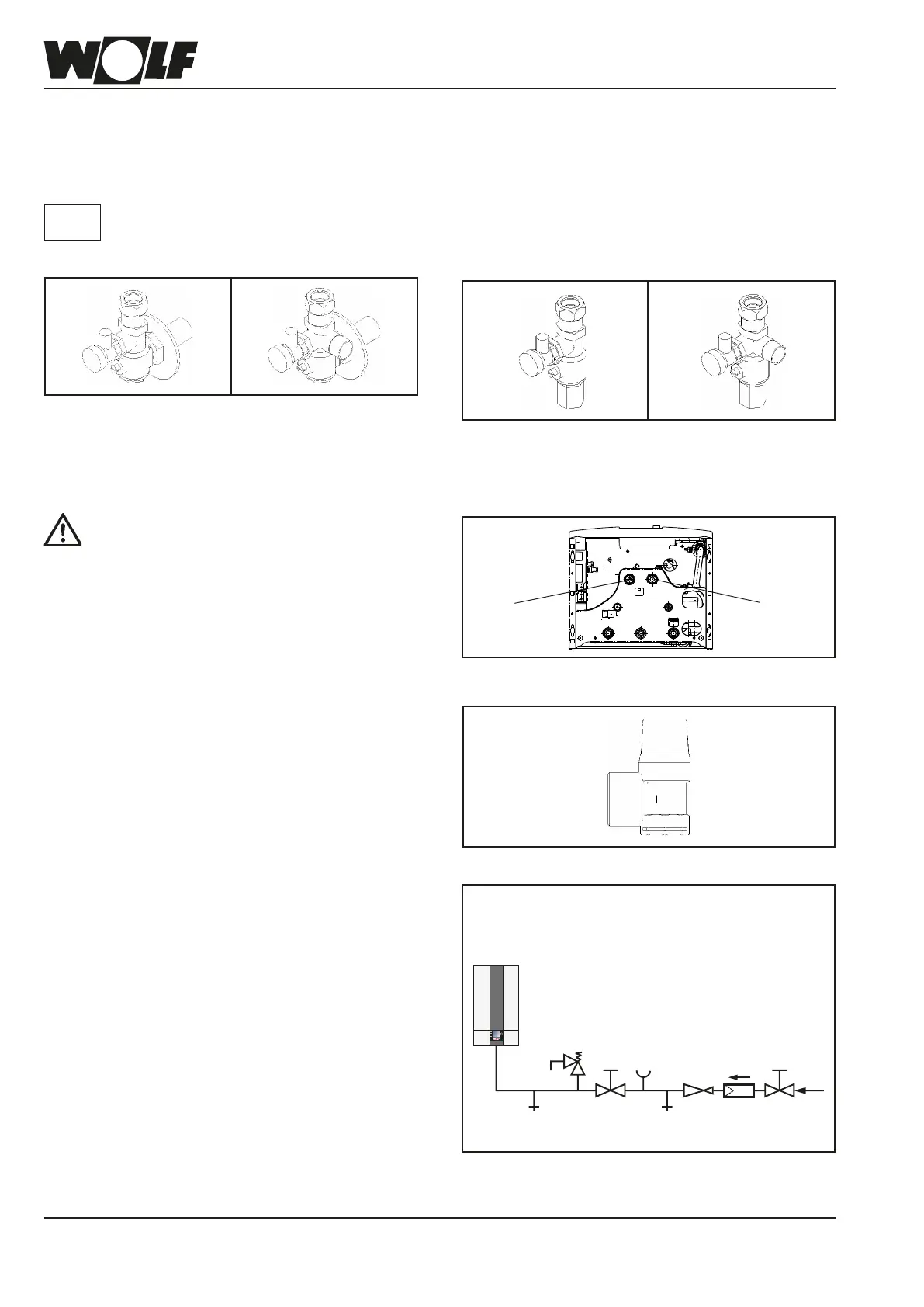

Fig: Cold water connection to DIN 1988

Cold water and DHW connection

A maintenance valve must be installed in the cold water

supply line.

We recommend installing a maintenance valve into the cold

water supply line.

If the cold water supply pressure is above the maximum

permissible operating pressure of 10 bar, install a tested and

certiedpressurereducerinaccordancewithWolfaccessories.

If mixer taps are used, provide a centralised pressure reducer.

Observe the regulations of DIN 1988 [Germany] as well as

those of your local water supply utility when connecting cold

water and DHW.

Your warranty is void if the installation does not comply with

the illustration shown.

Note: When selecting the installation material for the

system, observe engineering standards and take

into account possible electrochemical processes.

(Mixed installation)

Seite 14

Bild: Eckwartungshahn, mit KFE-Hahn (Zubehör)

Bild: Eckwartungshahn mit Anschluss für Sicherheitsventil,

mit KFE-Hahn (Zubehör)

Seite 14

Bild: Eckwartungshahn, mit KFE-Hahn (Zubehör)

Bild: Eckwartungshahn mit Anschluss für Sicherheitsventil,

mit KFE-Hahn (Zubehör)

Bild:

Durchgangswartungshahn,

mit KFE-Hahn (Zubehör)

Bild: Durchgangswartungshahn mit

Anschluss für Sicherheitsventil, mit

KFE-Hahn (Zubehör)

Bild:

Durchgangswartungshahn,

mit KFE-Hahn (Zubehör)

Bild: Durchgangswartungshahn mit

Anschluss für Sicherheitsventil, mit

KFE-Hahn (Zubehör)

Bild: Sicherheitsventil Heizkreis (Zubehör)

Safety valve

Drain outlet

Shut-off valve

Press. red. valve

Shut-off valve

Cold water supply

Drinkingwaterlter

Press. gauge connect.

Drain outlet

Installationonunnishedwalls

Installationonnishedwalls

OnboilersthatarenotusedforDHW,sealthe

cylinder ow and return connections tightly

with locking cap G¾" (accessories). Install a

safety valve with 3 bar opening pressure on site in

the heating return (see connection kit accessories).

Failure to observe this requirement can result in

material losses on building and equipment due to

uncontrolled water leakage.

Fig:Cylinderow/returnconnections

Cylinder return

G¾"

Cylinderow

G¾"

Loading...

Loading...