52 3064810_201804

25.Fillingtheheatingsystem/trap

Beforecommissioning,carryoutaleaktestonallhydraulicpipework

Iftheapplianceisnotwatertight,thereisariskofleaksandresulting

materialdamage.

Testpressureontheheatingwatersidemax.4bar

Priortotesting,closetheshut-offvalvesintheheatingcircuitforthe

appliance,asotherwise,thesafetyvalve(accessory)opensat3bar.

Theappliancehasalreadybeenleaktestedatthefactoryat4.5bar.

TreatmentofheatingwaterinaccordancewithVDI2035:

Potablewatermaybeusedasllingandtop-upwaterifthelimitsintable1arenot

exceeded. Otherwise, the water must be treated using a desalinisation process.

If the water quality does not meet the required values, the warranty for components

on the water side becomes void.

Theonlypermissiblewatertreatmentprocessisdesalinisation!

Thoroughlyushthesystempriortocommissioning.Inordertokeepoxygenation

aslowaspossible,itisrecommendedtoushthesystemusingtapwaterandthen

tousethiswaterforthewatertreatment(positionthedirtlterupstreamoftheion

exchanger).

Heatingwateradditivessuchasantifreezeorinhibitorsarenot

permitted,astheycandamagetheheatingwaterheatexchanger.

Alkalisingadditivesmaybeusedbyawatertreatmentspecialistto

stabilisethepHvalue.

In order to prevent corrosion damage to the aluminium heating water heat exchanger,

the pH value of the heating water must be between 6.5 and 9.0.

Inmixedinstallations,apHvalueof8.2to9.0mustbemaintainedin

accordancewithVDI2035.

The pH value should be checked again 8-12 weeks after commissioning, as under

certain circumstances, chemical reactions may cause it to change. If it does not fall

within this range after 8-12 weeks, remedial measures must be taken.

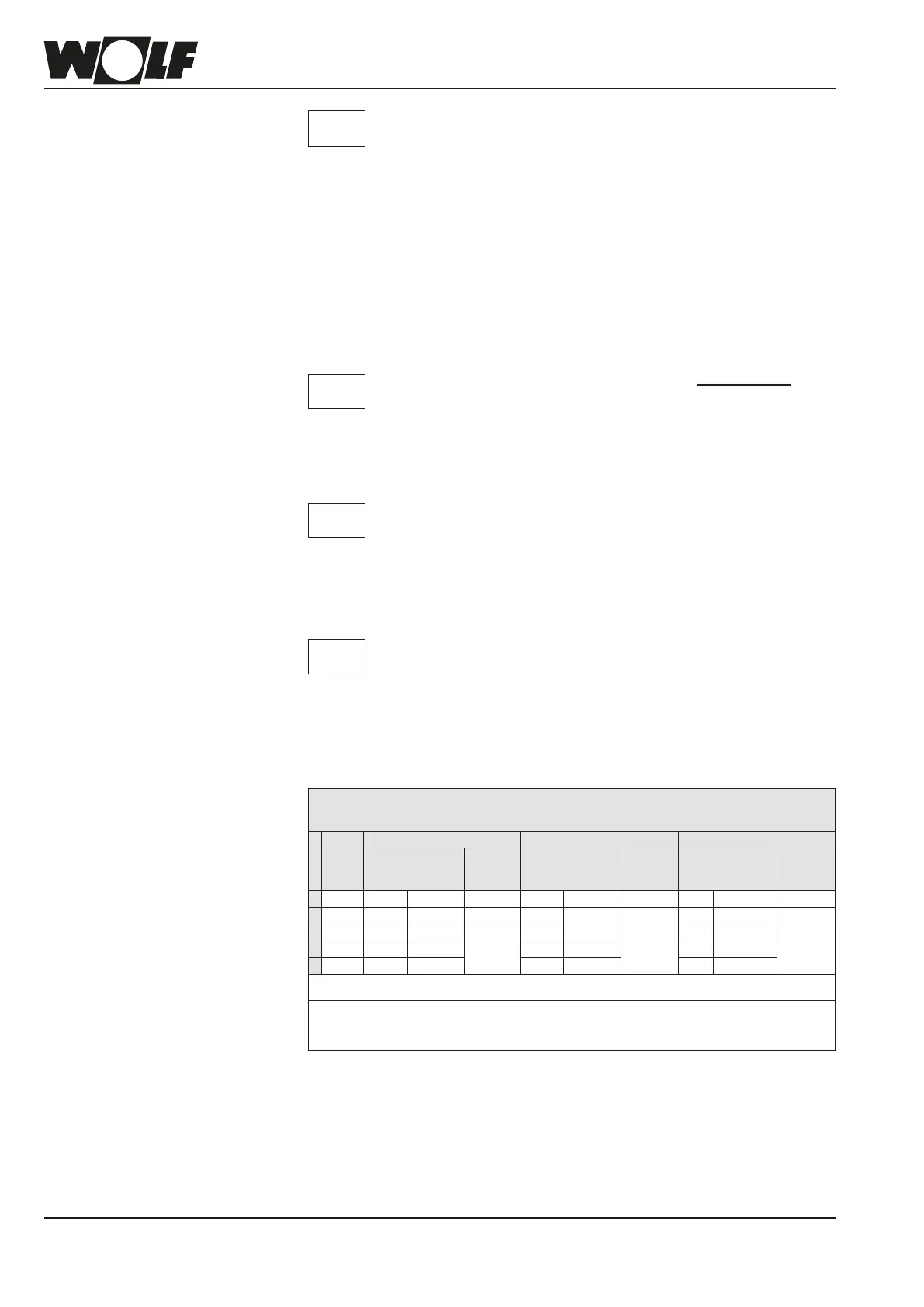

Heating water quality requirement relating to the entire heating system

LimitsinrelationtospecicsystemvolumeVA

(VA=systemvolume/max.ratedheatingoutput

1)

)

Totalhardnessconversion:1mol/m³=5.6°dH=10°fH

Total

heating

output

V

A

≤20l/kW V

A

> 20 l/kW and < 50 l/kW V

A

≥50l/kW

Total hardness / total

alkaline earths

Conduc-

tivity

2)

at 25°C

Total hardness / total

alkaline earths

Conduc-

tivity

2)

at 25°C

Total hardness /

total alkaline earths

Conduc-

tivity

2)

at 25°C

[kW] [°dH] [mol/m³] C [µS/cm] [°dH] [mol/m³] C [µS/cm] [°dH] [mol/m³] C [µS/cm]

1 ≤50 ≤16.8 ≤3.0 < 800 ≤11.2 ≤2 < 800 ≤0.11

3)

≤0.02 < 800

2 50-200 ≤11.2 ≤2

< 100

≤8.4 ≤1.5

< 100

≤0.11

3)

≤0.02

< 1003 200-600 ≤8.4 ≤1.5 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02

4 ≤600 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02

Thetotalamountofllandtop-upwateroverthelifecycleoftheboilermustnotexceedthreetimesthenominalvolumeofthe

heating system.

1)

According to VDI 2035, in systems with multiple boilers, use the maximum rated heating output of the smallest heat source

2)

High salinity < 800 µS/cm

Low salinity < 100 µS/cm

3)

< 0,11°dH recommended standard; permissible up to limit of < 1°dH

Table 1

Hydraulics

Please

note

Filling

Please

note

Please

note

Filling

Please

note

Electricalconductivityandwater

hardness

Loading...

Loading...