3064810_201804 53

25.Fillingtheheatingsystem/trap

Example:

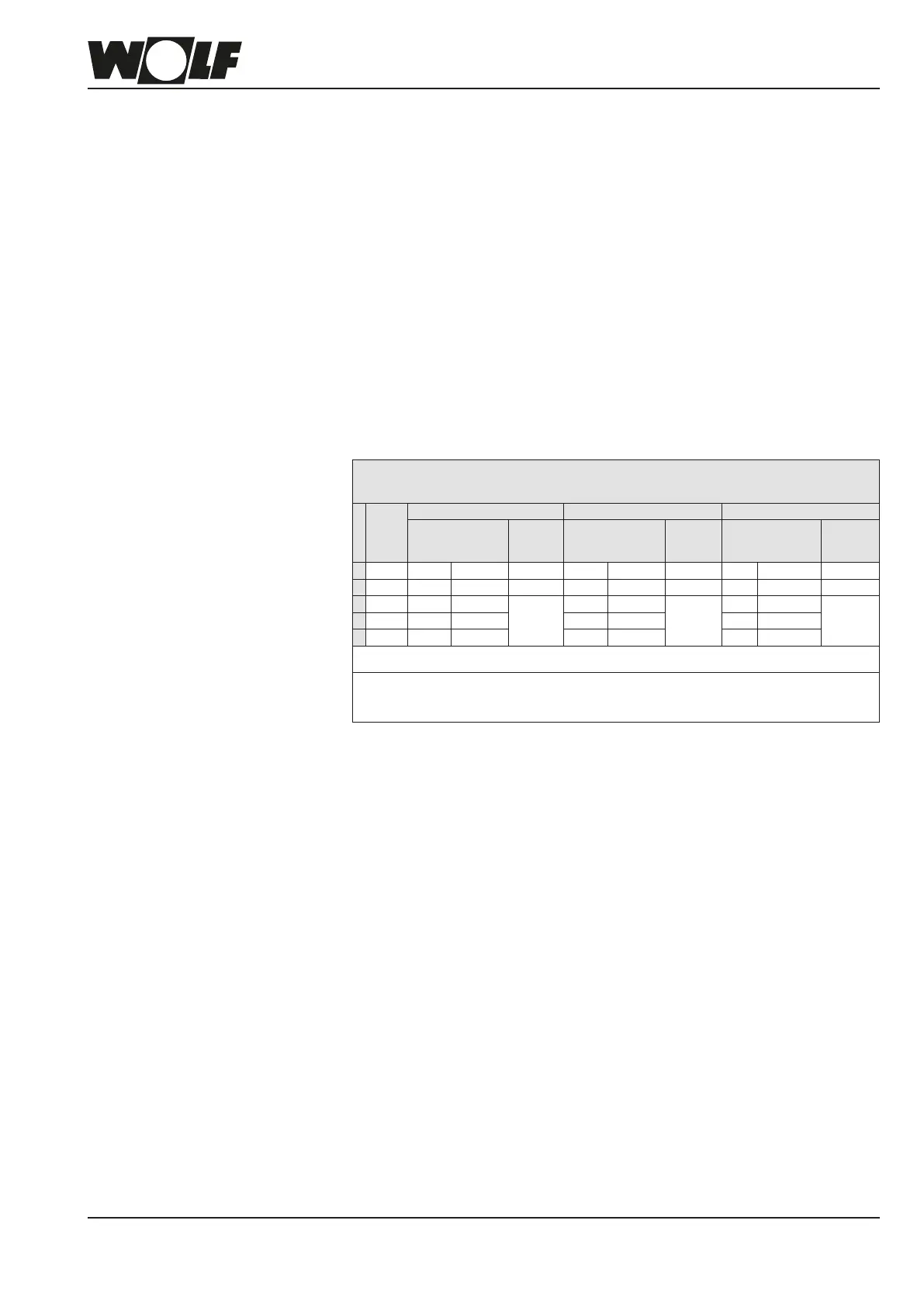

LimitsinrelationtospecicsystemvolumeVA

(VA=systemvolume/max.ratedheatingoutput

1)

)

Totalhardnessconversion:1mol/m³=5.6°dH=10°fH

Total

heating

output

V

A

≤20l/kW V

A

> 20 l/kW and < 50 l/kW V

A

≥50l/kW

Total hardness /

total alkaline earths

Conduc-

tivity

2)

at 25°C

Total hardness /

total alkaline earths

Conduc-

tivity

2)

at 25°C

Total hardness /

total alkaline earths

Conduc-

tivity

2)

at 25°C

[kW] [°dH] [mol/m³] C [µS/cm] [°dH] [mol/m³] C [µS/cm] [°dH] [mol/m³] C [µS/cm]

1 ≤50 ≤16.8 ≤3.0 < 800 ≤11.2 ≤2 < 800 ≤0.11

3)

≤0.02 < 800

2 50-200 ≤11.2 ≤2

< 100

≤8.4 ≤1.5

< 100

≤0.11

3)

≤0.02

< 1003 200-600 ≤8.4 ≤1.5 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02

4 ≤600 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02 ≤0.11

3)

≤0.02

Thetotalamountofllandtop-upwateroverthelifecycleoftheboilermustnotexceedthreetimesthenominalvolumeofthe

heating system.

1)

According to VDI 2035, in systems with multiple boilers, use the maximum rated heating output of the smallest heat source

2)

High salinity < 800 µS/cm

Low salinity < 100 µS/cm

3)

< 0.11°dH recommended standard; permissible up to limit of < 1°dH

System with a CGB-2-20 system volume = 800 l

Total hardness of untreated potable water = 18°dH

V

A

= 800 l / 20 kW = 40 l / kW

BecausethespecicsystemvolumeV

A

is between 20 and 50 l/kW with a total output

of<50kW,thellandtop-upwatermustbeintherangeof2to11.2°dHIfthetotal

hardnessoftheuntreatedpotablewateristoohigh,someofthellingandtop-upwater

must be desalinated.

A% desalinated water must be added.

A = 100% - [(C

max

-0.1°dH) / C

potable water

- 0.1°dH)] x 100%

C

max

: Maximum permissible total hardness in °dH

C

potable water

: Total hardness of untreated potable water in °dH

A = 100% - [(11.2°dH - 0.1°dH) / (18°dH - 0.1°dH)] x 100% = 38%

38%ofthellingandtop-upwatermustbedesalinated.

V

treatment

= 38% x 800 l = 304 l

Atleast304Lofdesalinatedwatermustbeaddedwhenllingthesystem.

The system can then be topped up with potable water.

Vent the system completely at the maximum system temperature.

The commissioning parameters must be recorded in the system log. This system log

must be handed to the system operator following commissioning of the system. From

that point onward, the operator is responsible for maintaining and keeping the system

log. The system log is provided with the accompanying documents.

The water values, in particular the pH value, electrical conductivity and hardness,

must be measured annually and documented in the system log.

Thetotalamountofllwaterusedoverthelifecycleoftheboilermustnotexceed

three times the system volume (oxygenation!). Where a system requires large

volumes of top-up water (e.g. more than 10 % of the system volume per year), the

cause must be sought immediately and the fault remedied.

Commissioning

Top-up water

Loading...

Loading...