74 3064810_201804

37.Technicalinformation,air/uegas

routing

Ifthegascondensingboilerisinstalledwithabalancedueroutedoveranexternalwall

(type C13x), the rated boiler output in heating mode must be reduced to below 11 kW

(for appropriate measures, see chapter "Limiting the maximum output").

Itmustbepossibletoinspecttheentirecross-sectionoftheues.Therefore,installan

appropriate cleaning and/or inspection aperture inside the boiler room; agree suitable

arrangementswithyourlocaluegasinspector.

Flue connections are created using couplings and gaskets. Always arrange couplings

againstthedirectionofthecondensateow.Installthebalanceduewithaslope

ofatleast3°towardsthegascondensingboiler.Installspacerclampstosecure

thepositioning(seeinstallationexamples).

Connectiontothebalancedue

Thecalculatedlengthofthebalanceduesystemortheueisderivedfromthestraight

pipe length and the length of any pipe bends.

Example for a 60/100 system

1)

:

Straight balanced ue pipe, length 1.5 m L = straight length + bend length

1 x 87° bend ≙ 1.5 m

L = 1.5 m + 1 x 1.5 m + 2 x 1.3 m

2 x 45° bends ≙ 2 x 1.3 m L = 5.6 m

Calculatingthe

balanceduelength

Note: Toavoidreciprocalinterferencebetweenairanduegaspipesroutedabove

the roof, we recommend maintaining a minimum clearance of 2.5 m between

the pipes.

1)

Equivalent length of the system:

60/100 80/125

87° bend 1.5 m 3 m

45° bend 1.3 m 1.5 m

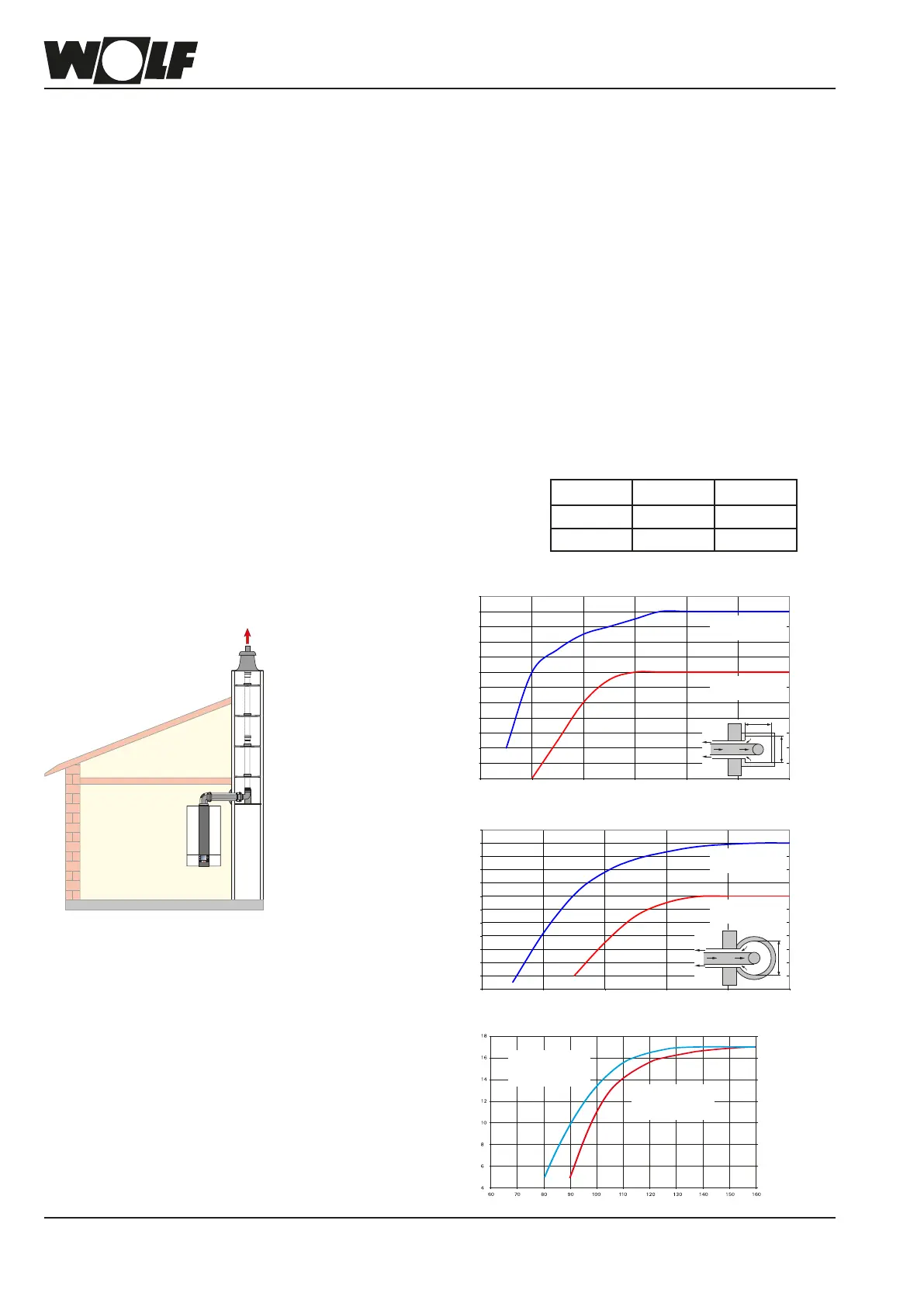

MinimumductsizeforroomsealedoperationC93x

Assuming: In the installation room:

2x inspection bends, 1x 87° bend and

1.5 m horizontal with 87° support bend

C93x

Flue pipe DN 80

8

9

10

11

12

13

14

15

16

17

18

19

20

100 110 120 130 140 150 160

Square duct [mm]

Connecting pipe

DN 60/100

Connecting pipe

DN 80/125

Max. vertical length [m]

a

8

9

10

11

12

13

14

15

16

17

18

19

20

110 120 130 140 150 160

Connecting pipe

DN 60/100

Connecting pipe

DN 80/125

Round duct [mm]

Max. vertical length [m]

Flue pipe DN 80

Max. duct length in [m]

Duct cross-section in [mm]

Connecting pipe

DN 60/100

round

Connecting pipe

DN 60/100

square

Flue pipe DN 60

Loading...

Loading...