3064810_201804 93

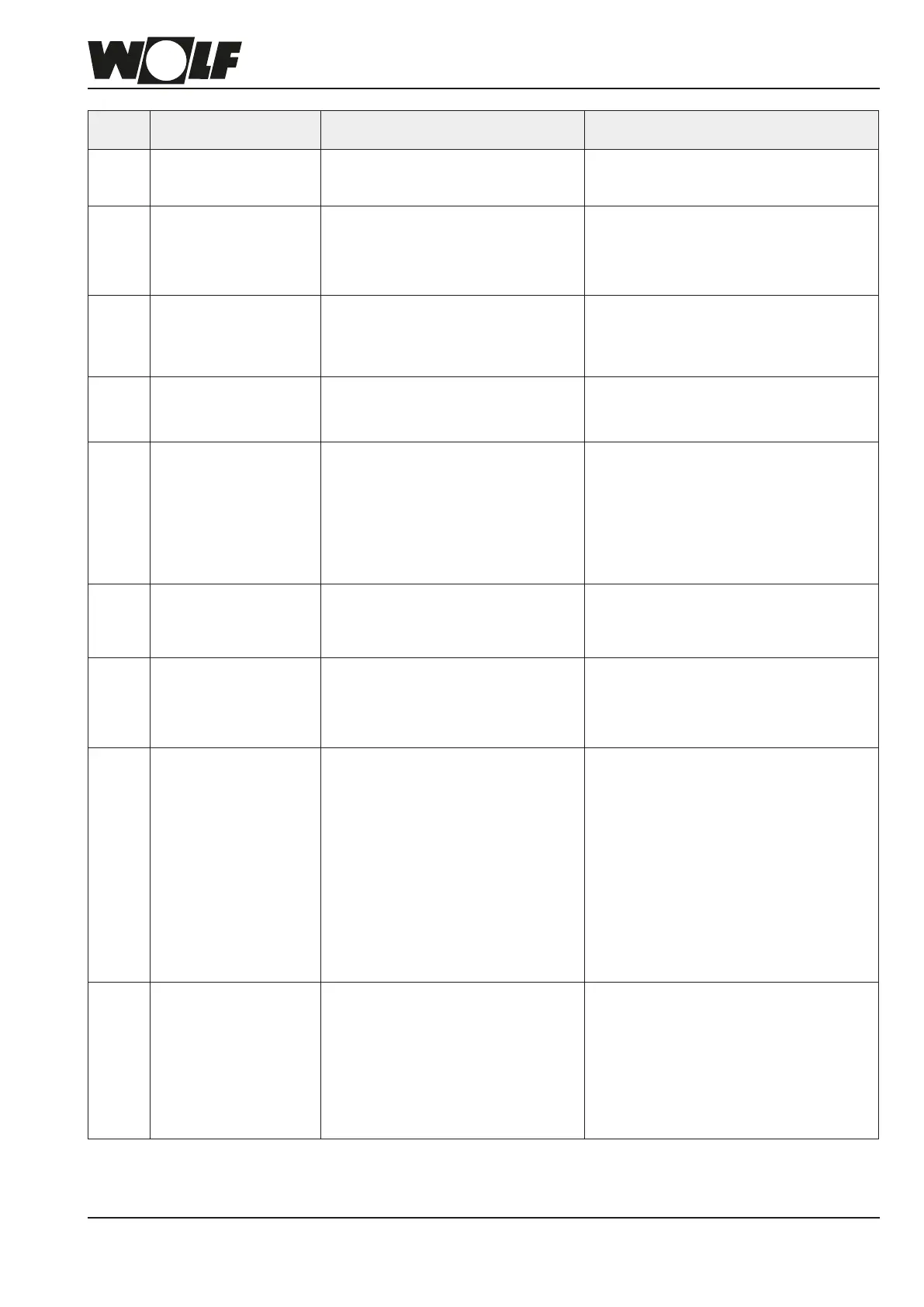

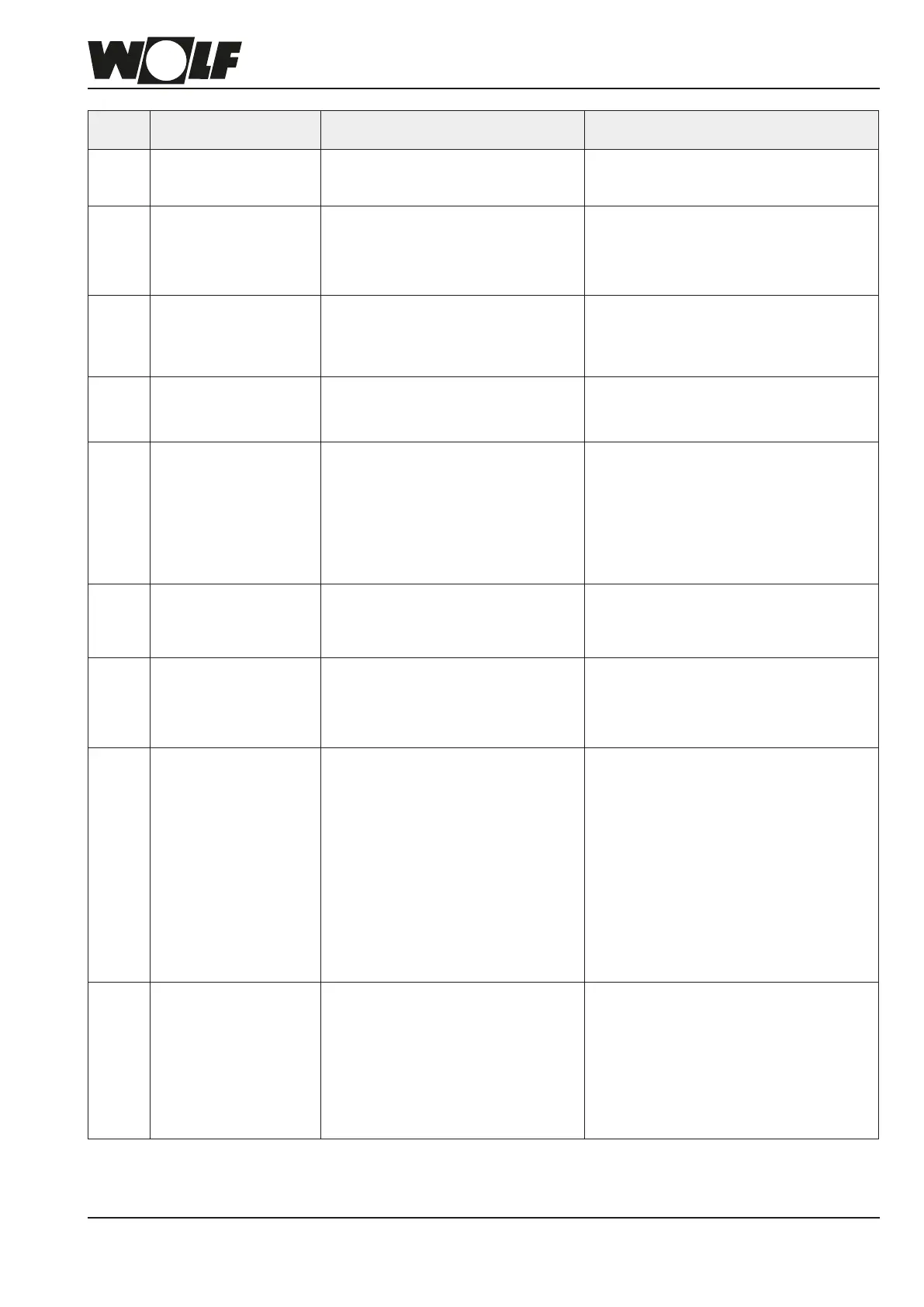

41.Troubleshooting

Fault

code

Fault Possiblecauses Remedy

30 CRC burner control unit The EEPROM record is invalid EEProm record invalid:

- Switch power supply OFF/ON.

- If fault persists, call out a contractor

32 23 V AC supply 23 V AC supply outside the permissible

range (e.g. short circuit)

Power supply unit:

- Switch power supply OFF/ON.

- Press reset button.

- If the fault cannot be acknowledged, re-

place HCM-2.

35 BCC missing Boiler coding card has been removed or

incorrectly inserted

Burner control unit was replaced and no

boiler coding card inserted

Boiler coding card has been removed or

incorrectly inserted.

Insert boiler coding card according to

appliance type.

36 BCC faulty CRC fault, BCC

Faulty boiler coding card

CRC fault, BCC:

- Replace boiler coding card.

Press reset button.

37 Incorrect BCC The boiler coding card is incompatible

with the GCB-e PCB

Incorrect BCC code

Use ON/OFF switch.

Boiler coding card incompatible.

Enter BCC code from the type plate correctly.

Insert the correct boiler coding card.

Press reset button and enter contractor code

1111.

38 BCC update required Boiler coding card fault; PCB requires a

new boiler coding card (replacement)

Reinsert boiler coding card.

Replace boiler coding card.

Press reset button.

39 BCC system error Faulty boiler coding card

BCC copy process not started

Use ON/OFF switch.

Replace boiler coding card.

Press reset button and enter contractor code

1111.

40 Flow monitoring

(pressure increase

check)

System pressure < 150 mbar

Air in heating circuit

Pressure sensor faulty

Faulty pump

Check system pressure.

Vent heating circuit.

Pressure sensor:

- Check leads and plug-in connections.

- If OK, replace pressure sensor.

Pump:

- Check if pump is running.

- If not, check cables and plugs.

- If electrical connection OK and no function:

Replace pump.

Press reset button.

41 Flow monitoring (check

sensor)

Return temperature > eHLSC

temperature + 12 K, return temperature

> boiler sensor + 12 K

System pressure too low

Air in heating circuit

Pump faulty/low output

Check system pressure.

Vent the system.

Flow monitoring:

- Increase minimum pump speed

Pump:

- Check if pump is running.

- If not, check cables and plugs.

- If electrical connection OK and no function:

Replace pump.

Loading...

Loading...