Commissioning

6720813171 (2015/04) 43

10.2.9 Measuring the flue gases CO

2

emissions

▶ Open at least 2 thermostatic radiator valves. Do not switch on the

boiler.

▶ Push on the control panel to open it ( fig. 68, page 32).

▶ Switch off the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Remove the cover from the flue gas measuring point [1].

▶ Connect the flue gas analyser to the left-hand measuring point.

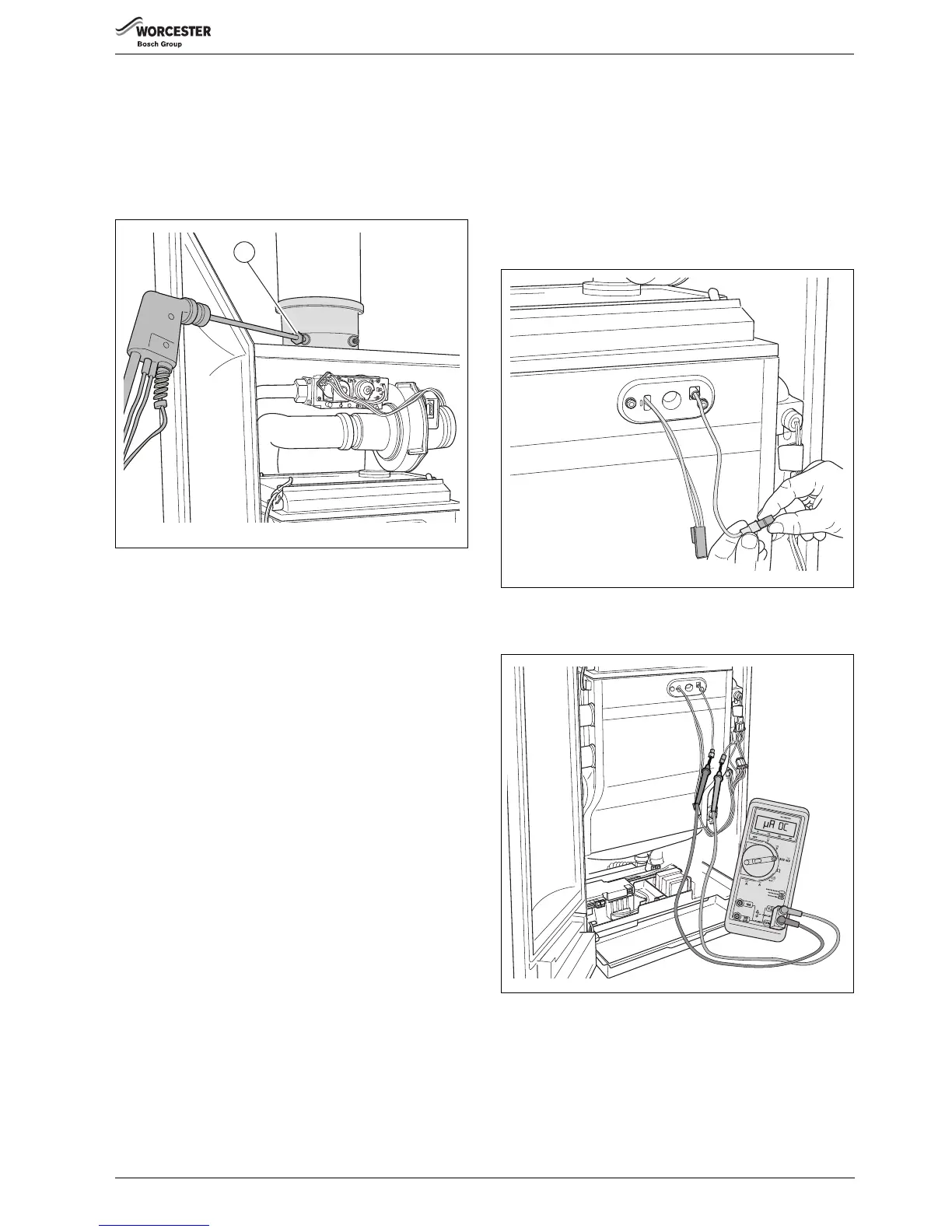

Fig. 91 Measuring the gas supply pressure

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Press and hold the “Chimney sweep” button ( fig. 90, [3])

(approximately 2 seconds), until the dot in the right-hand bottom

corner of the display ( fig. 90, [9]) appears. See also table 10,

“Flue gas test”, page 34.

▶ After the “Burner” LED ( fig. 90, [6]) has lit up wait for one minute

until the boiler is burning at full load.

▶ Measure the carbon monoxide content at the flue gas measuring

point ( fig. 91).

The CO values in air-free condition must be less than 400 ppm or

0.04 vol. %. Values of 400 ppm or more indicate an incorrect burner

adjustment ( section 10.2.7, page 41), a dirty gas burner or heat

exchanger or burner faults.

▶ You must determine and remove the cause ( chapter 12,

page 46).

▶ Press the “Chimney sweep” button ( fig. 90, [3]) to clear the

reading. See also table 10, “Flue gas test”, page 34.

▶ Switch off the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Remove the flue gas analyser and fit the cover back onto the flue gas

measuring point ( fig. 91, [1]).

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Press on the control panel to close it ( fig. 95, page 45).

10.2.10 Carrying out a function test

▶ During initial start-up and annual inspection and/or needs-oriented

servicing, make sure that all control, regulating and safety devices

are in full working order and, if applicable, check them for correct

adjustment.

▶ The gas and water circuits must be tested for leaks

( sections 10.2.1 and 10.2.8).

10.2.11 Measuring the ionisation current

▶ Push on the control panel to open it ( fig. 68, page 32).

▶ Open at least 2 thermostatic radiator valves. Do not switch on the

boiler.

▶ Switch off the heating system by pressing the mains switch of the

BC10 basic controller (

fig. 90, [1]).

▶ Turn the vent key through a quarter rotation to undo the boiler door

lock ( fig. 71, see detailed picture, page 37).

▶ Push the fastener down and open the boiler door ( fig. 71,

page 37).

▶ Undo the plug and socket connection of the monitoring cable.

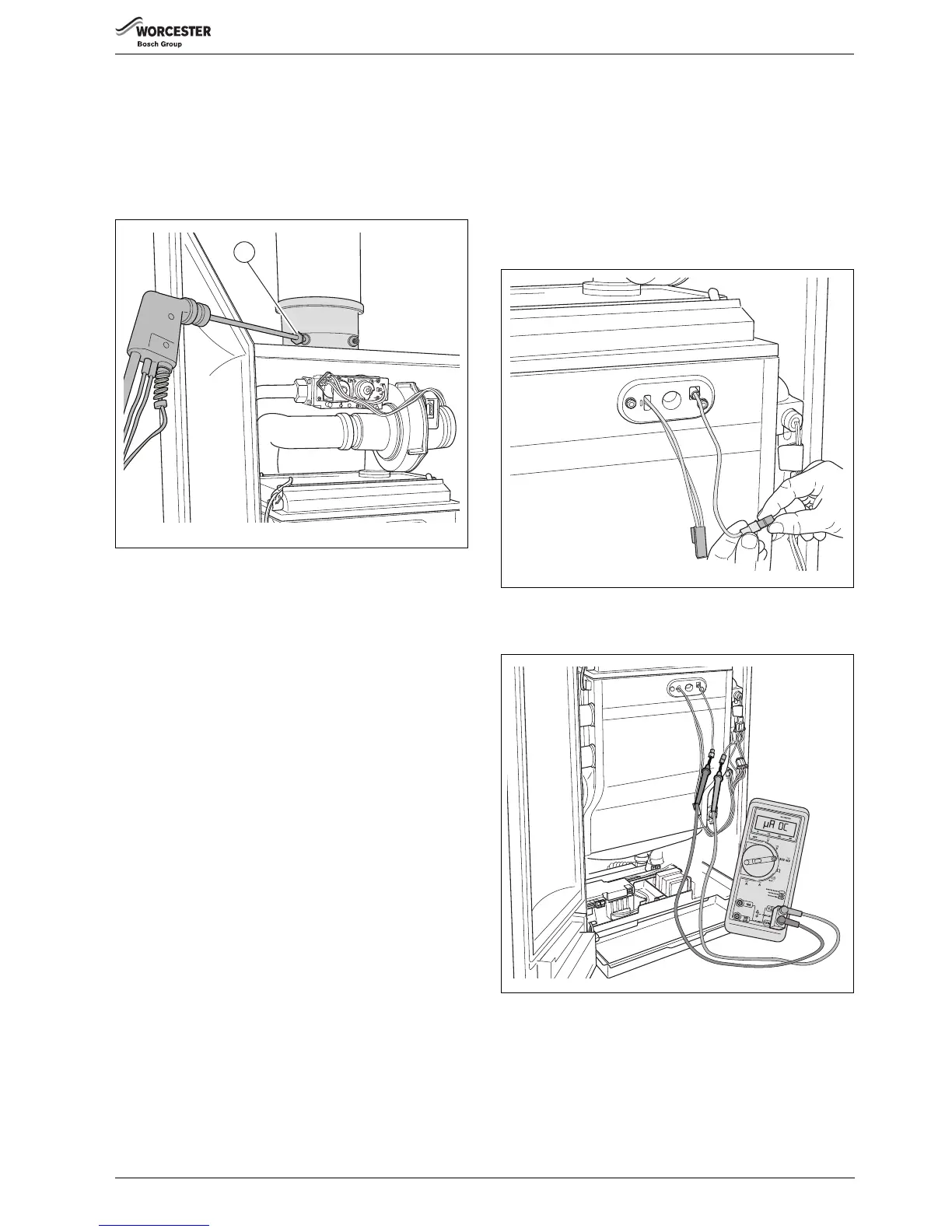

Fig. 92 Removing the ionisation electrode plug and socket connection

▶ Connect the multimeter in series. Select the μA DC range on the

multimeter. The multimeter must have a resolution of at least 1 μA.

Fig. 93 Measuring the ionisation current

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Activate the Service mode in accordance with the “Service mode”

menu ( table 11, page 34).

▶ Set the capacity to minimum (part load) according to the “Service

mode” menu ( table 11, page 34).

▶ After the “Burner” LED ( fig. 90, [6]) has lit up wait for one minute

until the boiler is burning at part load.

Loading...

Loading...