INSPECTION & SERVICE

INSPECTION & SERVICE

4

G

B

C

D

1

2

3

A

Primary Heat Exchanger:

There is a special accessory kit available (No.

840) specifically designed for cleaning the heat

exchanger. If required order 7 719 001 996.

1

Remove the cap (A) and connect a

manometer to the fan pressure test point.

After measurement replace test point

cap.

Pressure will read negative and be greater

than:

FS 30CDi - 4.1 mbar

FS 42CDi - 5.2 mbar

Pressures measured at less than these figures

will indicate that the heat exchanger will

require cleaning.

2

Remove the cleaning access cover (B),

seal (C) and metal plate (D) securing it, if

present.

3

Unscrew the condensation trap cap and

place a suitable container underneath.

To Remove Condensate pump:

Disengage condensate pipe from

condensate pump.

Remove condensate pump from base

panel.

After servicing the heat exchanger, fill

the condensate trap with approximately

1/4 litre of water and refit in reverse order.

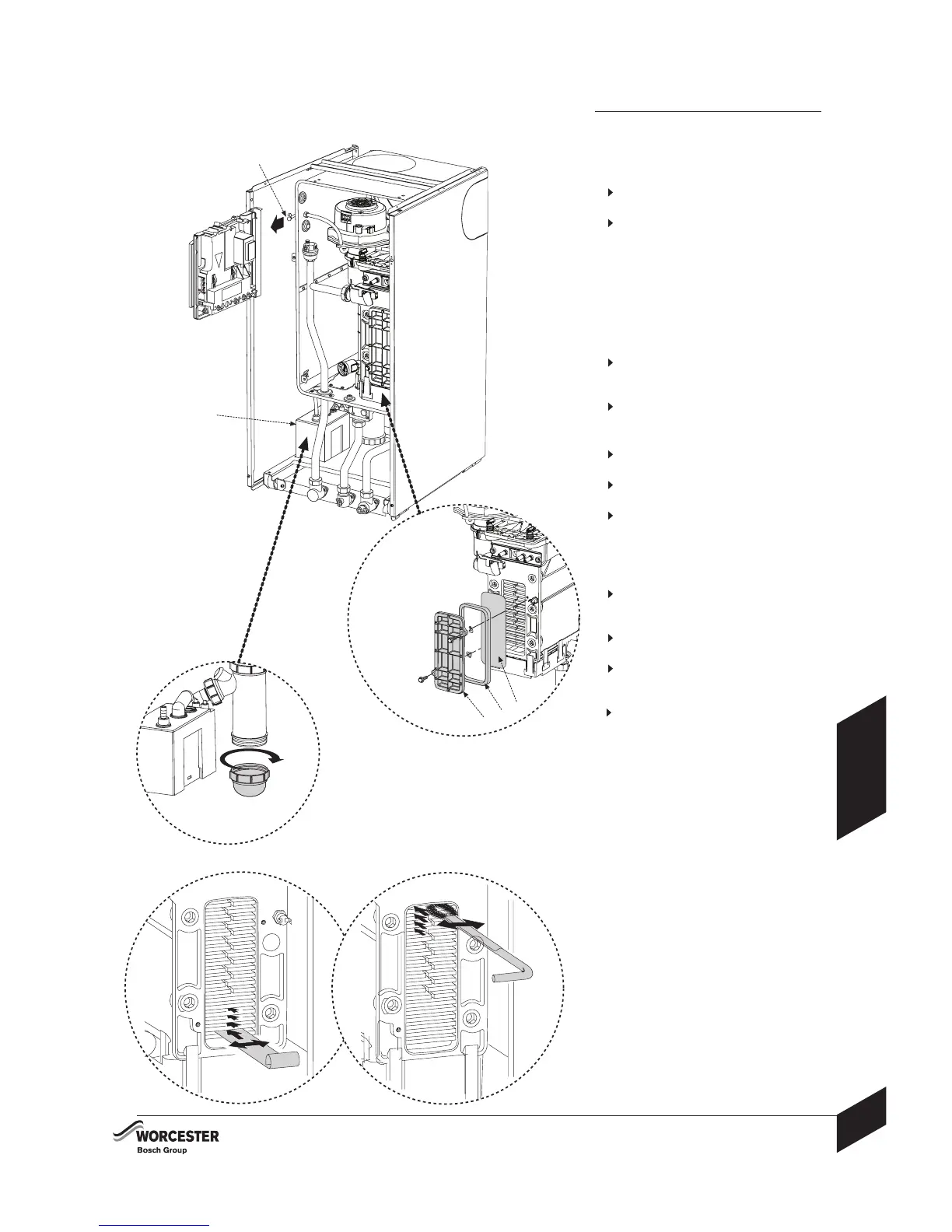

To Clean the Heat Exchanger:

4

Loosen any deposits in the heat exchanger

from top to bottom using the cleaning

blade.

Clean the heat exchanger from top to

bottom using the brush.

Refit the “clean out” coverplates in

reverse order using a new seal (C) and

tighten screws to a torque of 5 Nm.

After re-assembly check CO/CO2 levels

as described in the section “Setting the

air/gas ratio”

IMPORTANT: AFTER COMPLETING THE APPLIANCE SERVICE THE CO/CO

2 MUST BE

CHECKED AND SET TO THE LIMITS IN THE SECTION “AIR/GAS RATIO”.

SERVICING

& SPARES

INSTALLATION & SERVICING INSTRUCTIONS

35

8 716 115 216b (09.2008)

Loading...

Loading...