SERVICING

& SPARES

INSTALLATION & SERVICING INSTRUCTIONS

36

8 716 115 216b (09.2008)

INSPECTION AND SERVICE

INSPECTION AND SERVICE

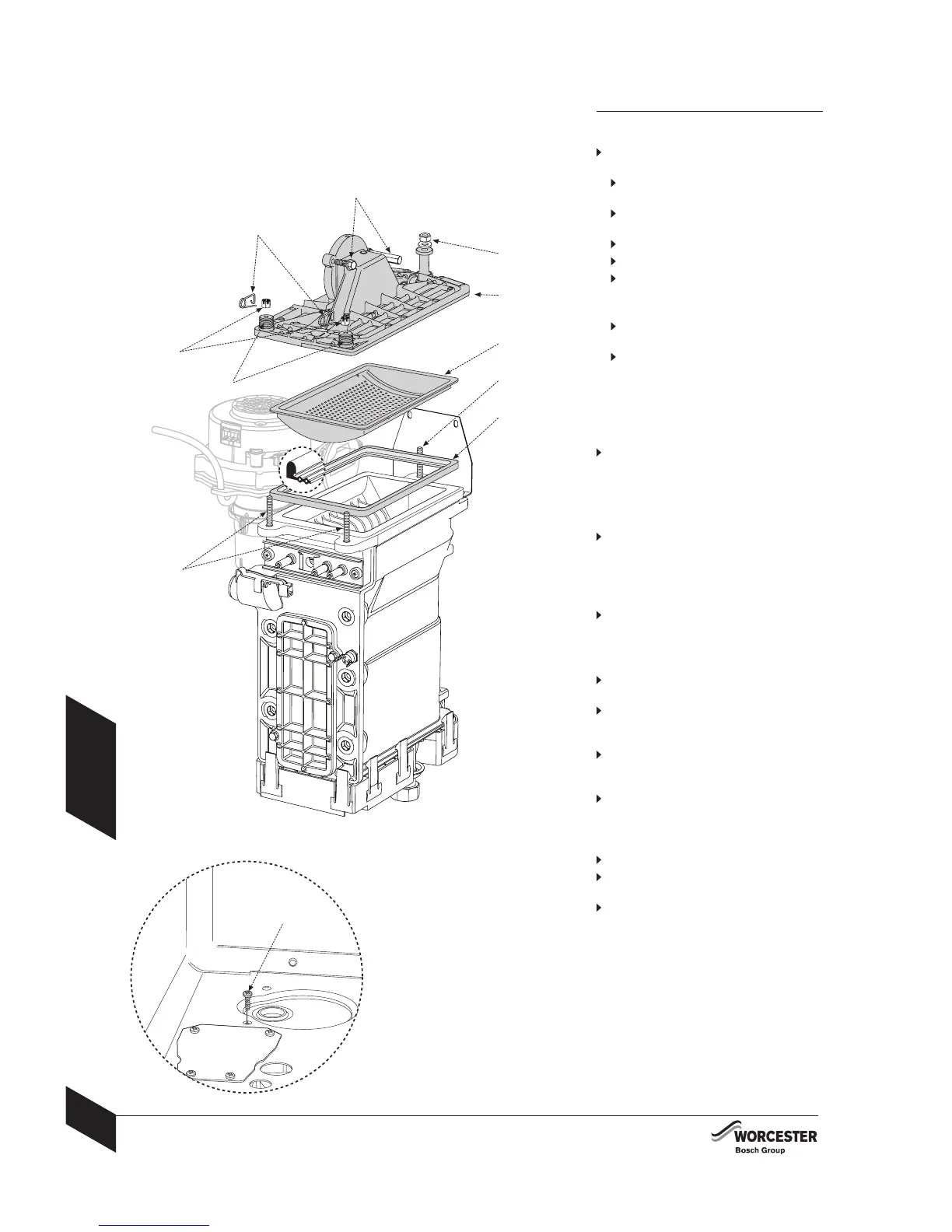

Burner:

Check that the boiler is completely isolated

from the gas supply.

1

Remove the clips (A), castellated nuts

(B1) and springs (B2) from the studs (B).

Unscrew and remove the two hexagon

headed screws (C) securing the fan.

Remove nut (D1) from the rear stud (D).

Remove the burner cover plate (E).

2

Remove the burner (F) and clean the

components.

Do not use a wire brush.

Re-assemble burner in reverse order

using a new seal (G).

After re-assembly check CO/CO2 levels

as described in the section “Setting the

air/gas ratio”

For sealed systems only:

Max pressure:

When the heating system water is at

maximum temperature, 2.65 bar must not

be exceeded. If this pressure is exceeded

then an extra expansion vessel must be

fitted into the system return as close as

possible to the appliance.

If the system does not retain the pressure,

the expansion vessel and the heating

system should be checked for leaks.

Electrical wiring:

Check the electrical wiring for physical

damage and replace any damaged wires.

To check the flap valve in fan intake:

Refer to page 38 for access to the fan

intake.

Carefully withdraw the flap valve from fan

intake tube and check for soiling and splits,

clean or replace as required.

Take care when refitting the flap valve, the

flaps must open upwards into the fan intake

tube.

After re-assembly check CO/CO2 levels

as described in the section “Setting the

air/gas ratio”

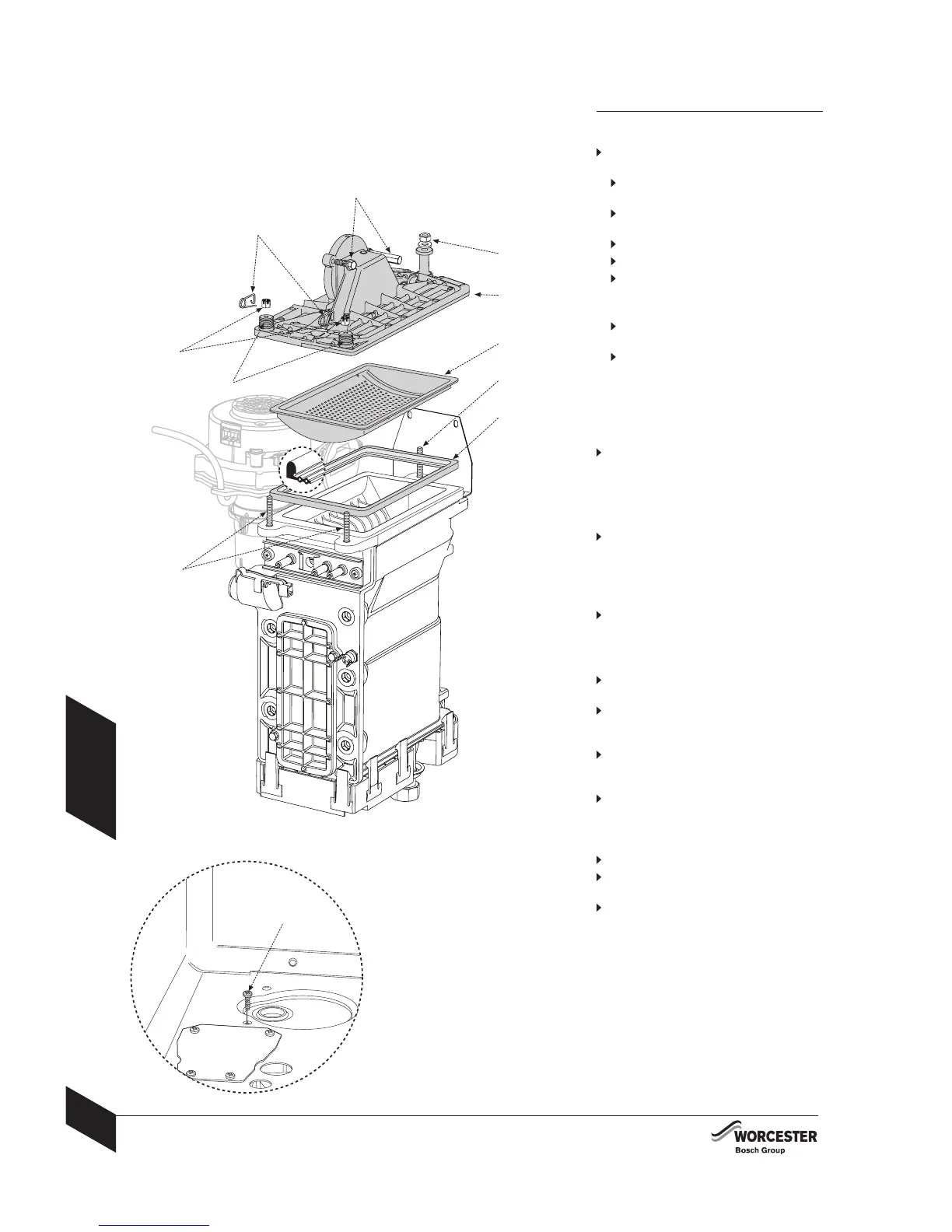

To clean the condensate trap:

Remove pipe from condensate pump.

Remove screw retaining trap (F) and push

trap downwards until clear.

Remove trap from boiler along with pipe

to condensate pump.

F

A

B1

C

D1

F

G

B

D

E

B2

Loading...

Loading...