SERVICING AND SPARES

6720818077 (2016/04) - Greenstar Highflow CDi

ErP

37

▶ If further adjustment is required, remove the combustion chamber

cover and set adjuster [3] as necessary

▶ Replace the cover and check the maximum CO

2

again

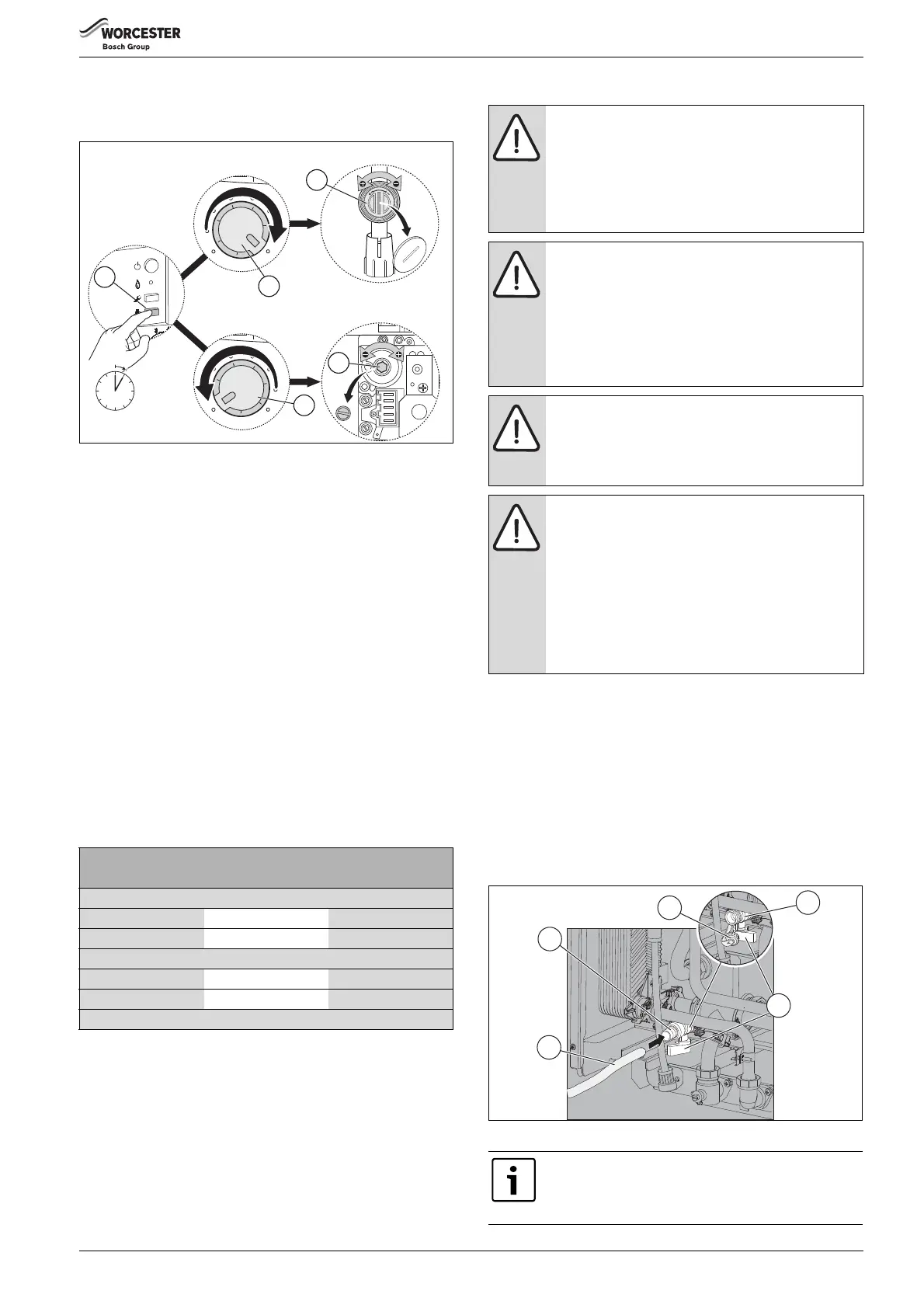

Fig. 57 Setting air/gas ratio

To set the minimum CO

2

:

▶ Turn the temperature control [2] to minimum. This will make the

boiler go to minimum output, allow the output to settle for

approximately 10 minutes

▶ Remove the dust cap and adjust [4] on the gas valve

▶ Measure the minimum CO

2

and compare with the minimum output

shown on the table 15

▶ Check that the CO is less than 200ppm

▶ Repeat the procedure until the correct output is achieved

Confirm the maximum CO

2

▶ Turn temperature control to maximum output and recheck the CO

2

.

If correct, hold down the Service engineer button [1] for two

seconds, the boiler should return to normal operating mode with the

blue power indicator permanently illuminated

▶ Remove the flue gas analyser

▶ Replace the cap over the flue gas sample point

▶ Remove the combustion chamber cover

▶ Replace the dust cover over the minimum output adjuster [4]

▶ Replace plastic cover to maximum outlet adjuster [3]

▶ Replace the combustion chamber cover

6.9 Replacement parts

6.9.1 Draining the appliance

▶ Turn off the system heating flow and return isolation valves - external

to boiler.

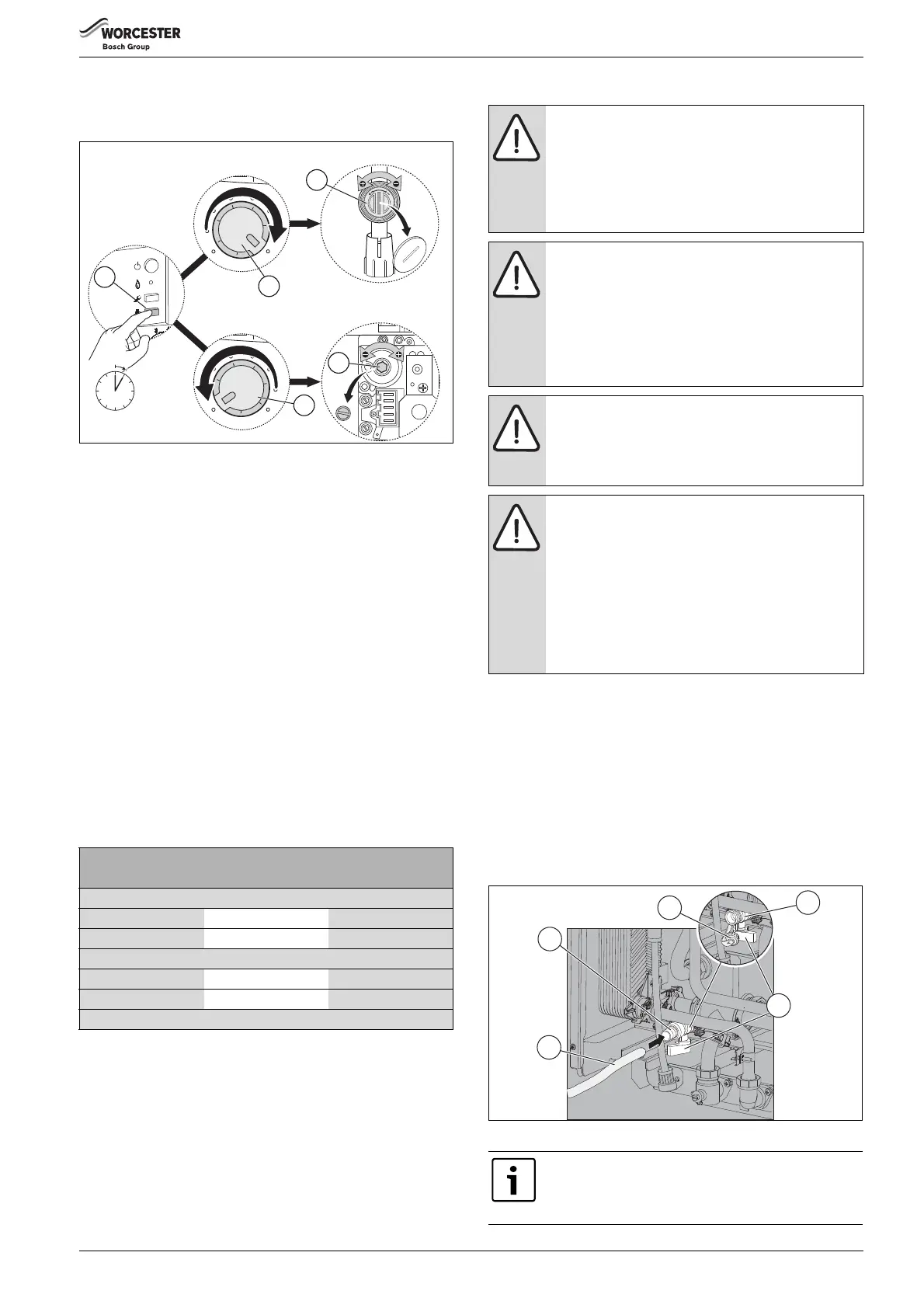

▶ Unscrew the tank drain cap from the tank drain valve [1].

▶ Connect the hose connection and nut [4] (supplied with boiler,

literature pack) to the tank drain valve [2].

▶ Attach a suitable hose [5], to the hose connector at the tank drain

valve and route the other end of the hose to an external drain point.

▶ Fully open the drain tap [3] on the tank drain valve [1].

▶ Close the drain tap [3] when the flow from the appliance has stopped

and remove the hose.

Fig. 58 Draining the boiler

GAS TYPE CO

2

setting max. CO

2

setting min.

The CO

2

should be measured after 10 minutes

Greenstar HF 440CDi

ErP

Natural Gas 9.4 ± 0.2% 8.6 ±0.2%

LPG (propane) 10.8 ± 0.2% 10.4 ±0.2%

Greenstar HF 550CDi

ErP

Natural Gas 9.4 ± 0.2% 9.0 ±0.2%

LPG (propane) 10.8 ± 0.2% 10.4 ±0.2%

CO - less than 200 ppm (0.002 ratio)

Table 15 CO/CO

2

settings

6720648568-42.1Wo

Max adjustment

Max mode

Service

mode

Min adjustment

Min mode

≈

10 s10 s

1

2

2

4

3

CAUTION: Isolate the boiler

▶ Turn off the gas supply and isolate the mains

electrical supply before starting any work and

observe all relevant safety precautions.

▶ Drain the boiler/system where necessary and protect

any electrical equipment from water ingress during

component replacement.

NOTICE: Gaskets and O rings

▶ Refit or replace any components removed from the

appliance in the reverse order using new gaskets/'O'

rings/sealant/heat transfer paste where necessary.

▶ Any 'O' ring or gasket that appears damaged must be

replaced. Always check that any electrical

connections are correctly made and that all screws

are tight.

NOTICE: AFTER REPLACEMENT OF ANY

COMPONENTS ALWAYS CHECK FOR GAS

TIGHTNESS WHERE RELEVANT AND CARRY OUT

FUNCTIONAL CHECKS AS DESCRIBED IN THE

COMMISSIONING SECTION.

NOTICE: Service work

▶ Any service work must be carried out by competent

registered gas engineer, such as a British Gas or

other GAS SAFE registered engineer.

▶ After re-assembly the combustion must be checked

using the procedure in the section “Setting the air/

gas ratio”. Measurement and setting of the gas ratio

must not be attempted unless the person is equipped

with a combustion analyser conforming to BS 7927

and is competent in its use.

A small quantity of water may remain in some

components even after the appliance has been drained.

Protect any electrical components when removing

components from the water circuits.

Loading...

Loading...