SERVICING AND SPARES

6720818077 (2016/04) - Greenstar Highflow CDi

ErP

41

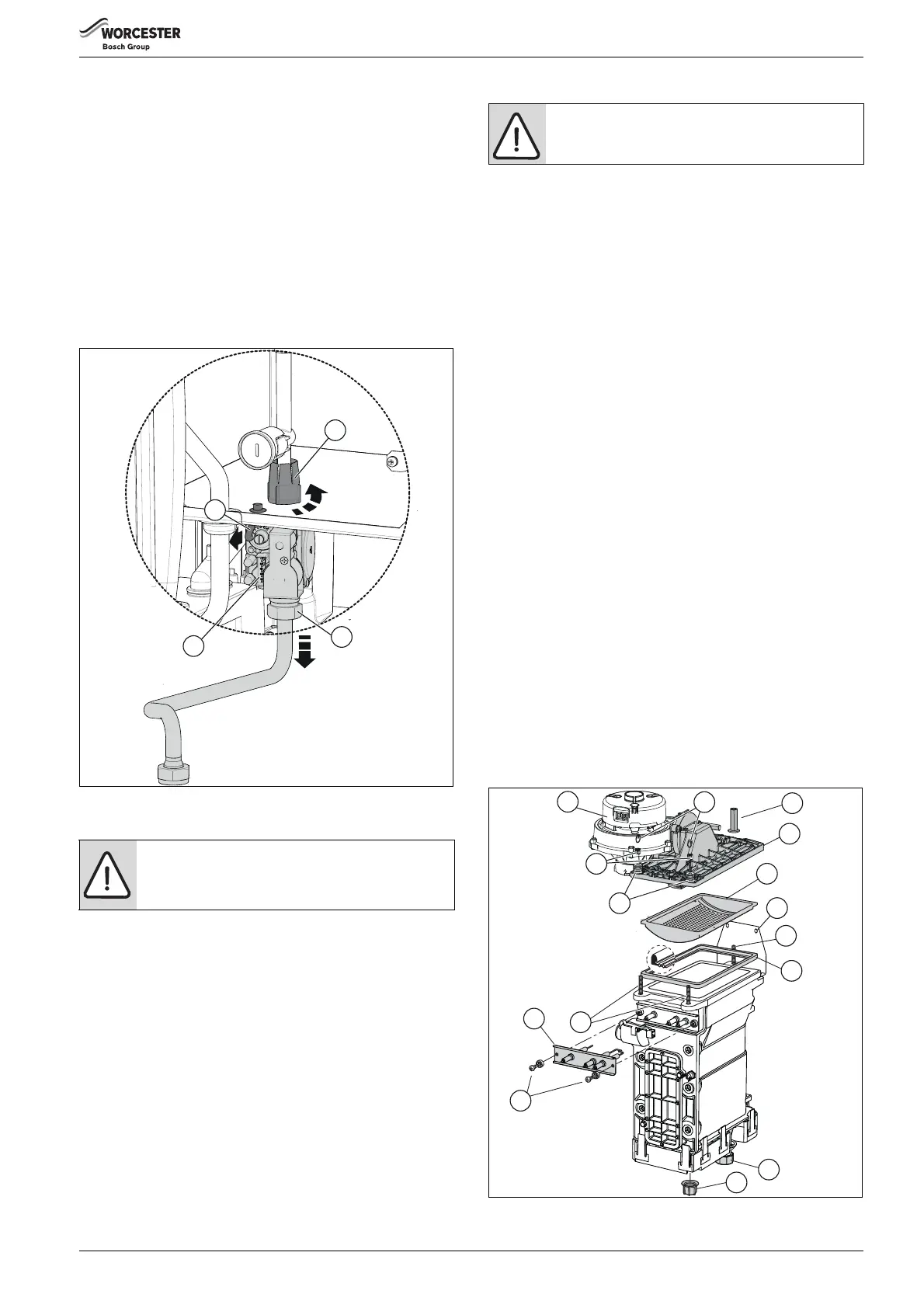

6.9.15 Gas valve

▶ Check that the gas cock is turned off.

▶ Disconnect the black rubber tube [1] from the gas valve.

▶ Remove the solenoid connections [2] at the side of the gas valve.

▶ Release the gas inlet union [3] at the inlet.

▶ Undo the union [4], within the inner casing, securing the valve to the

gas/air tube.

▶ Transfer the inlet pipe assembly to the new gas valve.

▶ Reconnect the plastic union [4] to the gas valve.

▶ Reconnect the solenoid connection [2].

▶ Re-attach the black rubber tube [1] to the gas valve

▶ Check for gas tightness when the new gas valve has been fitted.

▶ After re-assembly check CO/CO

2

levels as described in the section

“Setting the air/gas ratio” on page 36.

Fig. 67 Gas valve

6.9.16 Electrode assembly and heatshield

▶ Switch off the master switch.

▶ Isolate the appliance from the power supply.

▶ Move the control panel and expansion vessel into the service

position.

▶ Release the 4 screws to remove the inner case door.

▶ Remove the leads from the electrodes.

▶ Unscrew the two fixing screws [2] and carefully remove the

electrode assembly [1].

▶ Inspect the spark/flame electrode assembly and ceramics for signs of

contamination or damage, replace as necessary.

▶ Re-assemble the electrode set with a new gasket and secure with the

screws [2] removed earlier.

▶ After re-assembly check that the CO/CO

2

levels as described in the

section “Setting the air/gas ratio” on page 36.

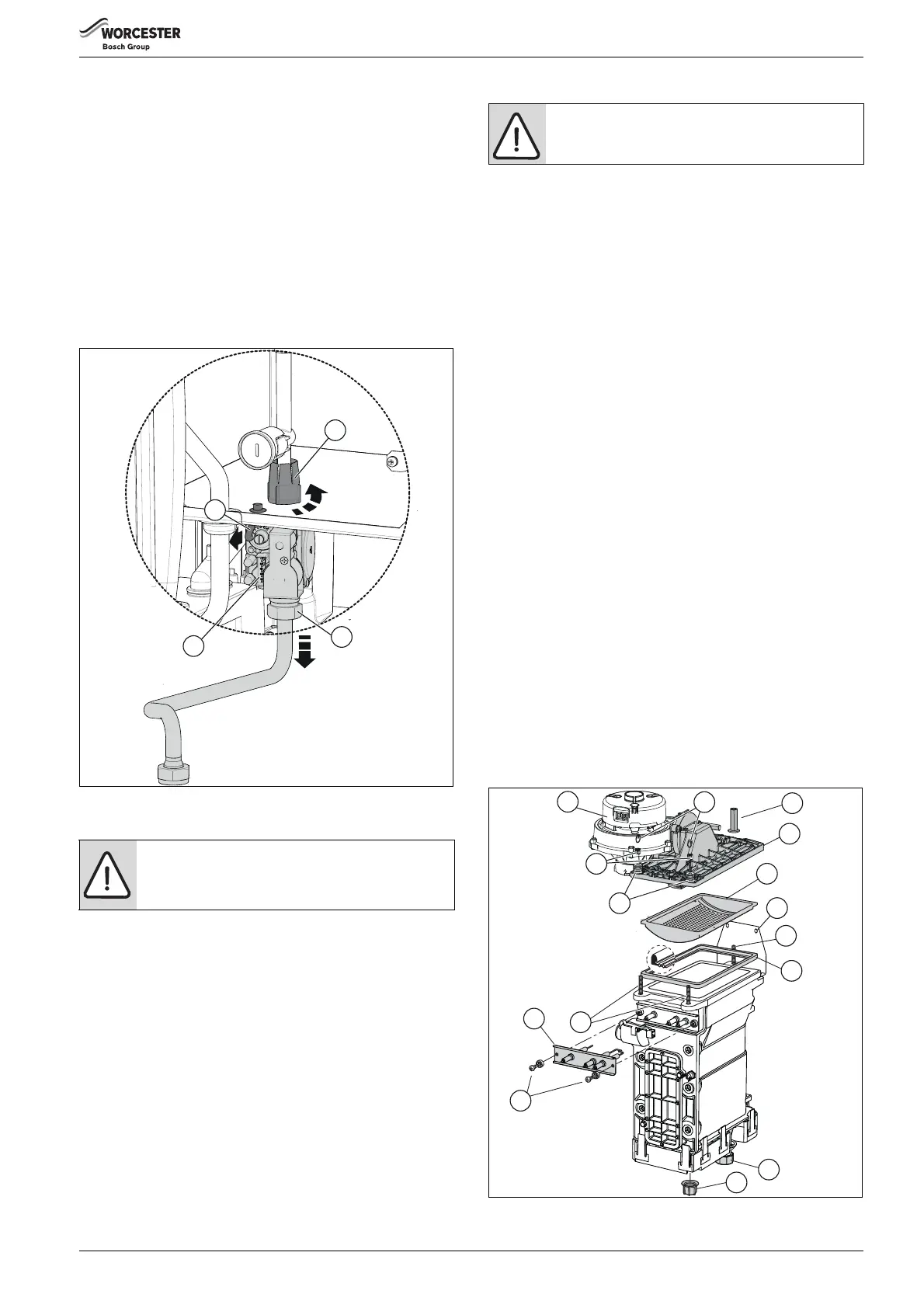

6.9.17 Burner

▶ Turn the gas cock and the master switch to their OFF positions.

▶ Isolate the appliance from the power supply.

▶ Remove the clips [3a], castellated nuts [3b] and springs [3c] from

the studs [3].

▶ Remove the nut [4a] from the rear stud [4].

▶ Disconnect the mixer unit from the fan.

▶ Remove the connector and earth wire from the fan.

▶ Remove the burner cover plate [5] and fan assembly [6].

▶ Remove the burner [7].

▶ Re-assemble the new burner in reverse order.

▶ Replace the burner seal [8] with a new one.

▶ Refer to the section “Re-assembly of the burner cover” on page 36.

▶ After re-assembly check that the CO/CO

2

levels as described in the

section “Setting the air/gas ratio” on page 36

6.9.18 Primary heat exchanger:

▶ Isolate the appliance from the power supply.

▶ Turn off all the isolation valves.

▶ Drain down the appliance.

▶ Move the control panel and the expansion vessel into the service

position.

▶ Remove the inner case door.

▶ Remove the fan assembly, burner, and gas mixing unit.

▶ Disconnect and remove the sensors connected to heat exchanger.

▶ Remove the condensate trap.

▶ Remove the internal flue elbow and tube from the boiler sump.

▶ Release the return pipe union [10] at the base of the heat exchanger.

▶ Remove the plastic nut [11] from the base of the inner casing.

▶ Release the retaining bracket [9] from the inner chassis

▶ Remove the heat exchanger from inner casing.

▶ Ensure that heat conductive paste is used on sensors when refitting.

▶ Check the seals and replace if necessary.

▶ After re-assembly check that the CO/CO

2

levels are as described in

the section “Setting the air/gas ratio” on page 36.

Fig. 68 Primary heat exchanger

WARNING: Electrode assembly

▶ Do not remove the electrode assembly unless a new

gasket is available for re-assembly.

WARNING: Burner

▶ Do not remove the burner unless a new gasket is

available for re-assembly.

6720818079-26.1Wo

1

2

3

9

4

5

4a

7

8

11

10

3a

3b

3c

6

Loading...

Loading...