SERVICING AND SPARES

Greenstar Highflow CDi

ErP

- 6720818077 (2016/04)40

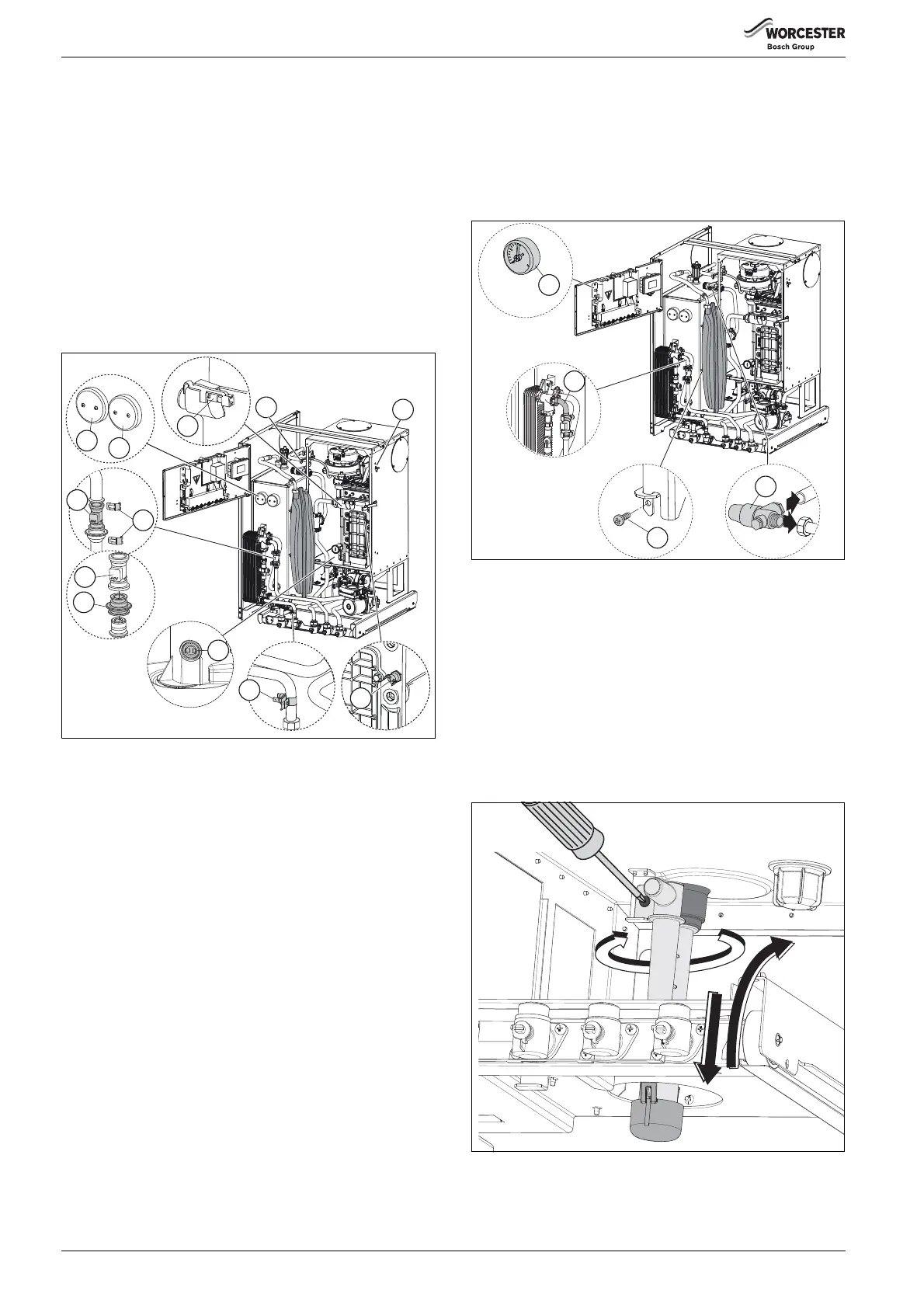

Flue Temperature limiter [9]

▶ Remove the connector.

▶ Using a small terminal screwdriver, prise the sensor and grommet

from the plastic housing. Take care not to damage the plastic

housing.

Domestic hot water temperature sensor[10]:

▶ Release and pull-off the electrical connectors.

▶ Unscrew the bracket.

▶ Replace the sensor coating surface with paste supplied.

▶ Re-assemble ensuring the sensor is in contact with the flat section of

pipe.

Safety temperature limiter [11]:

▶ Remove the connectors.

▶ Unscrew the sensor.

Fig. 64 Sensors

6.9.10 Domestic hot water heat exchanger

▶ Before removing the heat exchanger, close the mains water inlet

isolation valve and drain the hot water circuit. Close the CH isolating

valves and drain the appliance.

The pipe [2] may be removed between the flow sensor outlet and the

plate heat exchanger to improve access to the rear connections.

▶ Undo the two screws securing the plastic housing to the heat

exchanger.

▶ Remove the heat exchanger.

▶ To refit, follow the above in reverse. Ensure any seals that have been

disturbed are replaced.

6.9.11 Pressure gauge:

▶ Drain the appliance.

▶ Unplug the connection to the pressure relief valve.

▶ Release the pressure gauge from the clips on the rear of the control

panel.

6.9.12 Expansion vessel:

▶ Drain the appliance.

▶ Move the control panel into service position.

▶ Remove the locking screw [3] from vessel bracket.

▶ Undo the union connection at the top of the vessel.

▶ Swing the expansion vessel out and lift off the brackets.

▶ Set the pressure of the new vessel to that required by the system.

6.9.13 Pressure relief valve PRV:

▶ Drain the appliance.

▶ Disconnect the drain pipe from the valve [4]

▶ Undo the nut retaining the PRV to the flow pipe.

▶ Remove the clip from the PRV and disconnect the pressure gauge.

▶ Remove the valve.

▶ Replace the sealing washer and fit a new valve.

Fig. 65 Replacement parts

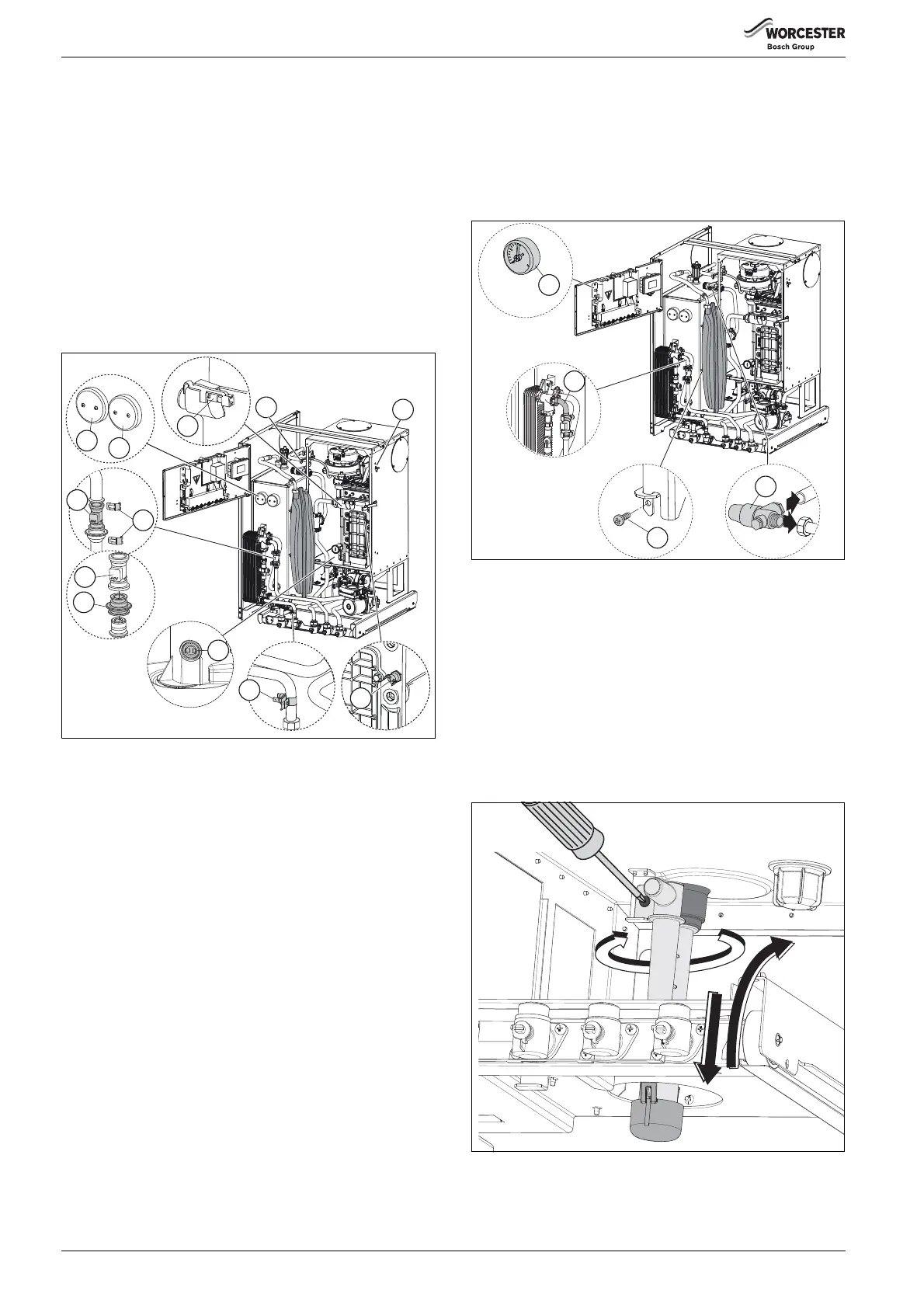

6.9.14 Condensate trap

▶ Remove the condensate pump, refer to section 6.9.4 on page 38

▶ Remove the screw retaining the trap

▶ Rotate the condensate trap by 90°

▶ Pull the trap down from the sump connection

▶ Angle the trap backwards and remove from the boiler

▶ Before replacing the trap, fill with at least 250ml of clean water

▶ Replacing the trap is the reverse of the removal procedure

▶ Reconnect the condensate pump and reconnect the pipe from the

trap

▶ Reconnect the condensate disposal pipe

Fig. 66 Condensate trap access

6720818077-17.1Wo

5

2

1

3

9

10

11

4

6

7

6

8

Loading...

Loading...