SERVICING AND SPARES

Greenstar Highflow CDi

ErP

- 6720818077 (2016/04)38

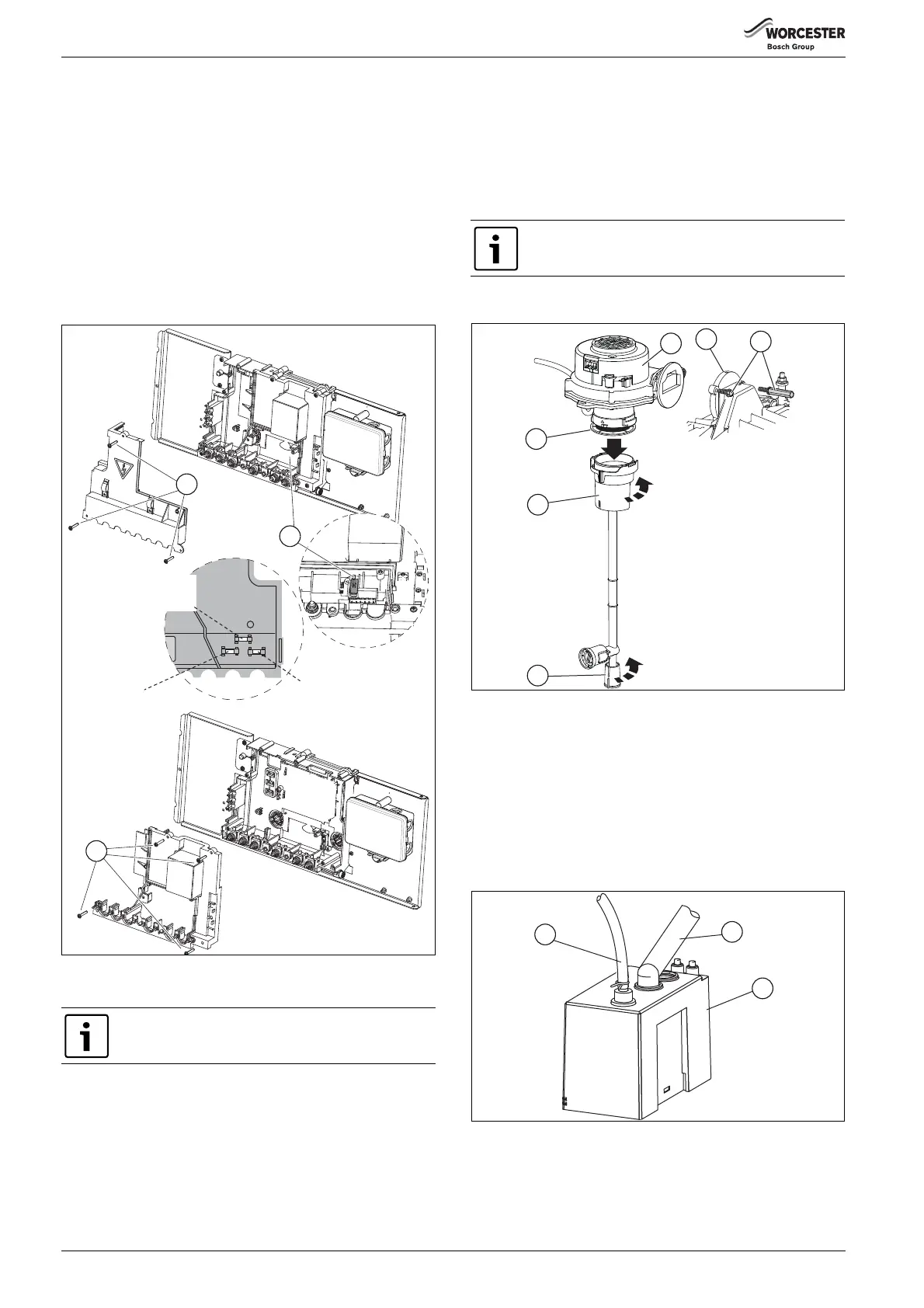

6.9.2 PCB Control board

Access to boiler control components

▶ Remove the screws [1] to release the cover from the controller.

PCB Fuse

▶ Remove the fuse [2] and replace with a spare that is clipped on the

inside of the controller cover.

PCB

▶ Disconnect all electrical connections from the control board.

▶ Remove the screws [3] retaining the rear panel of the control and

remove the panel.

▶ After re-assembly check CO/CO

2

levels as described in the section

“Setting the air/gas ratio” on page 36.

Fig. 59 PCB

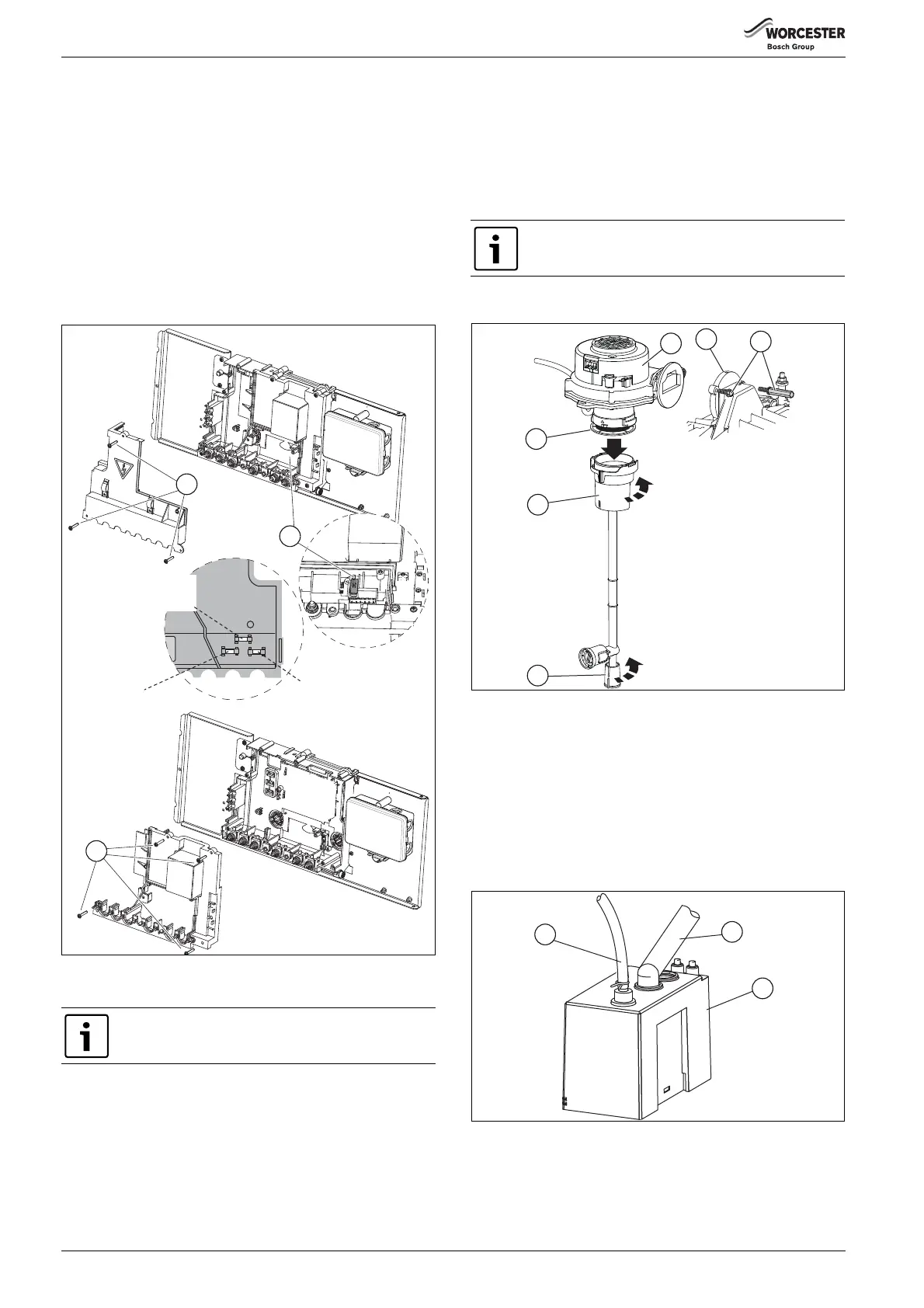

6.9.3 Fan assembly:

▶ Undo lower pipe union on gas pipe [5].

▶ Twist the mixer unit [4] with gas pipe [5] to separate from fan [1].

▶ Remove fan lead and earth connector.

The earth connector has a positive clip fixing.

▶ Remove fixing screws [3] attaching fan [1] to the burner cover [2].

▶ Remove fan [1].

▶ After re-assembly check that the CO/CO

2

levels are as described in

the section “Setting the air/gas ratio”.

Flap Valve:

▶ Undo lower pipe union on gas pipe [5].

▶ Remove pipe [5] by pushing upwards and towards the rear of the

boiler.

▶ Twist the mixer unit [4] with gas pipe [5] to separate from the fan

[1].

▶ Remove flap valve [6] from within fan intake [1] and replace.

▶ After re-assembly check that the CO/CO

2

levels are as described in

the section “Setting the air/gas ratio” on page 36.

Fig. 60 Fan assembly

6.9.4 Condensate pump

▶ Disconnect electrical connections in control box, see wiring

schematic in the ‘Fault finding and Diagrams’ section 7, page 43.

▶ Rotate the 15mm flexible tube [1] anti-clockwise and pull up to

remove from the pump.

▶ Remove black flexible pipe [2] from condensate pump. Take care as

there maybe condensate remaining in the pipe.

▶ Carefully remove the condensate pump [3] from the boiler and pour

any excess condensate into a suitable container for safe disposal.

Fig. 61 Condensate pump

Do not attempt to service the fan assembly and flap

valve if a CO/CO

2

analyser is not available.

6720818077-22.1Wo

T2.5A H250V F1

T500mA L250V F3

Spare Fuse order

T1.6A L250V F2

1

2

3

Ensure the flap valve is fitted correctly with rubber flap

upwards.

6720818079-10.1Wo

1

2

3

4

5

6

Loading...

Loading...