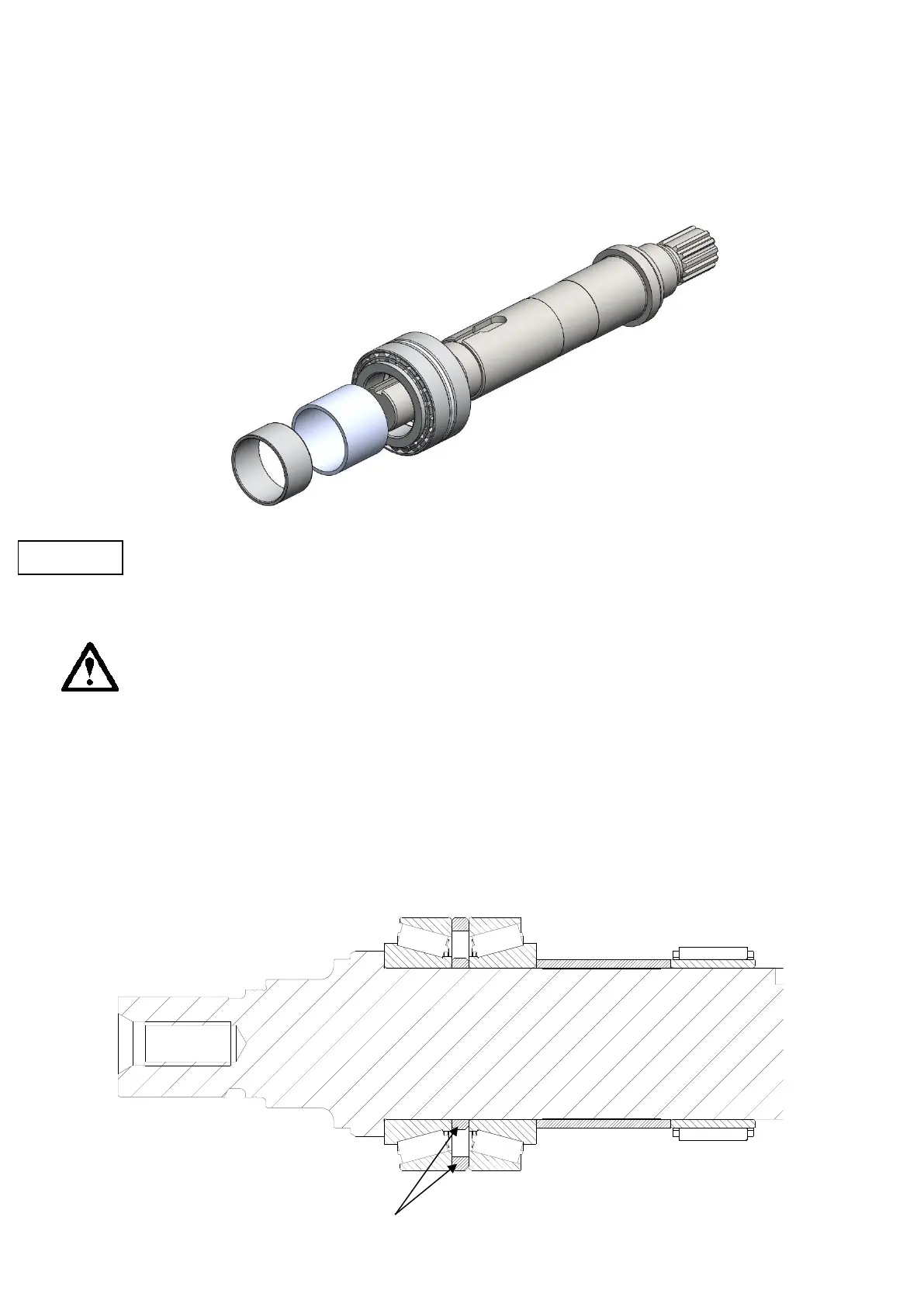

4.2 Assembly.

4.2.1 Shaft Assembly.

Fig 22

• The tapered roller bearings have matched pre-load spacers; these set the

rolling torque and must be kept with the matching bearings.

The preferred method of installing bearing cones is that they are heated to

approximately 125°C (250°F) prior to installation. During this operation

protective gloves should be used. Once bearing cones are installed in the

correct position they should be allowed to cool before proceeding with

assembly. After bearings cool they need to be pressed to assure they are

fully seated. Press to 15 tons make sure necessary procedures are used to

prevent component damage. During assembly press taper bearings onto

shaft then press roller bearing onto shaft.

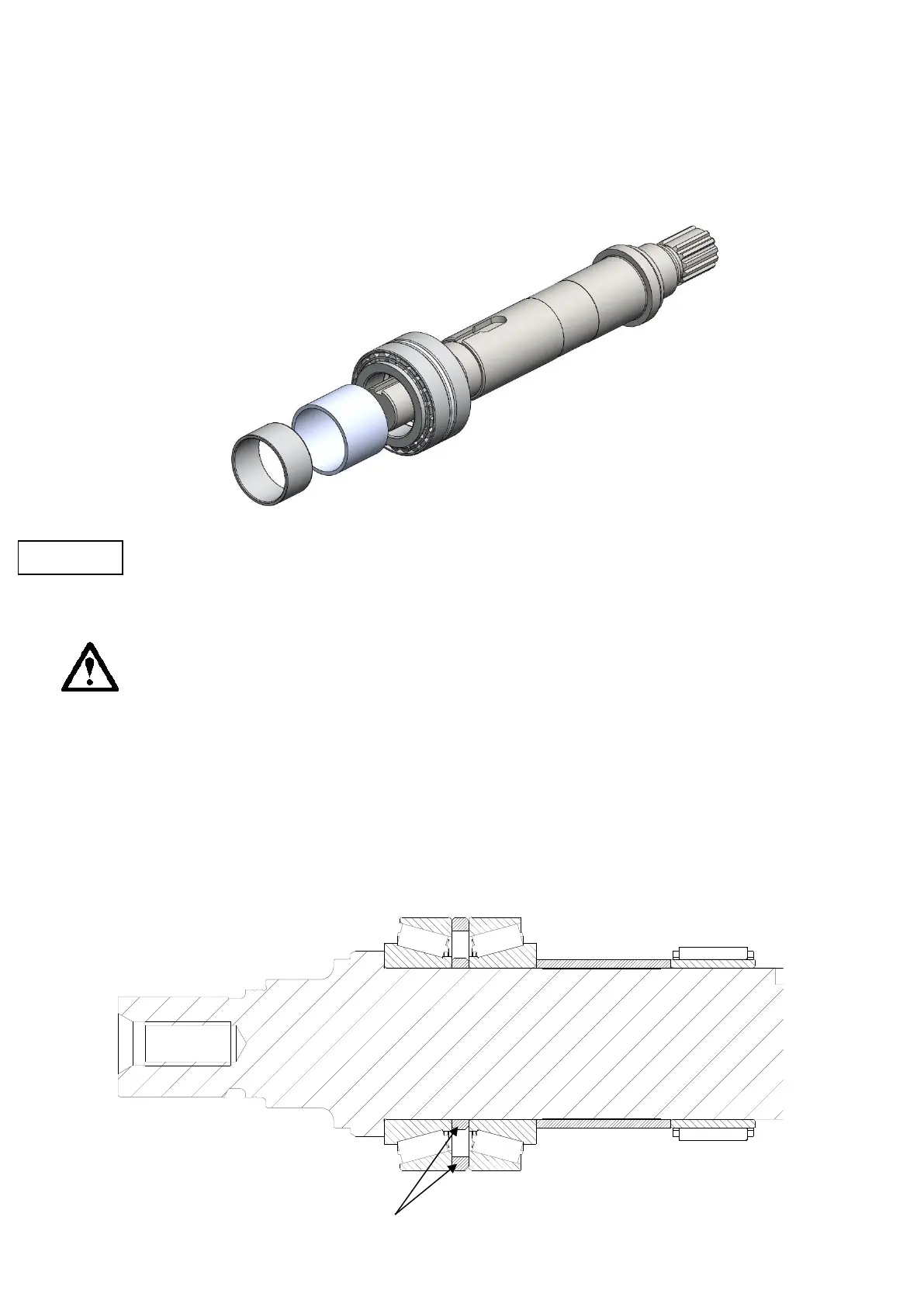

Under no circumstances should bearing cones or cups be hammered

into position.

Fig 23

Loading...

Loading...