DIRECTION OF ROTATION

The Revolution-series mechanical seals are independent of the direction of rotation.

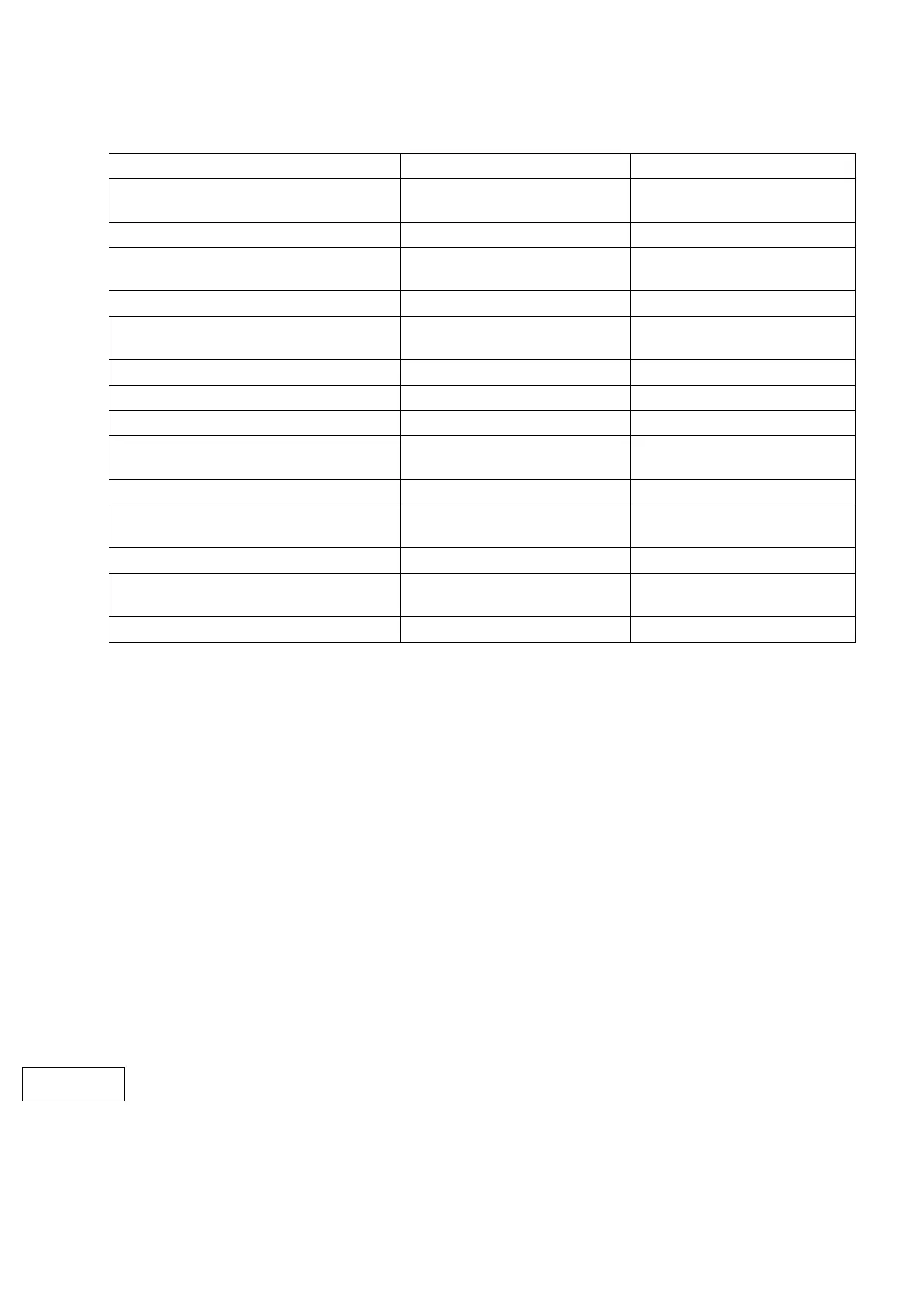

TEMPERATURE LIMITS

Following temperature limits apply to the different seal faces commonly used within

mechanical seals:

Seal face max operating temperature, dependent on liquid being processed

Solid Resin-impregnated Carbon 200°C

Inserted Carbon 150°C

Solid Silicon Carbide 250°C

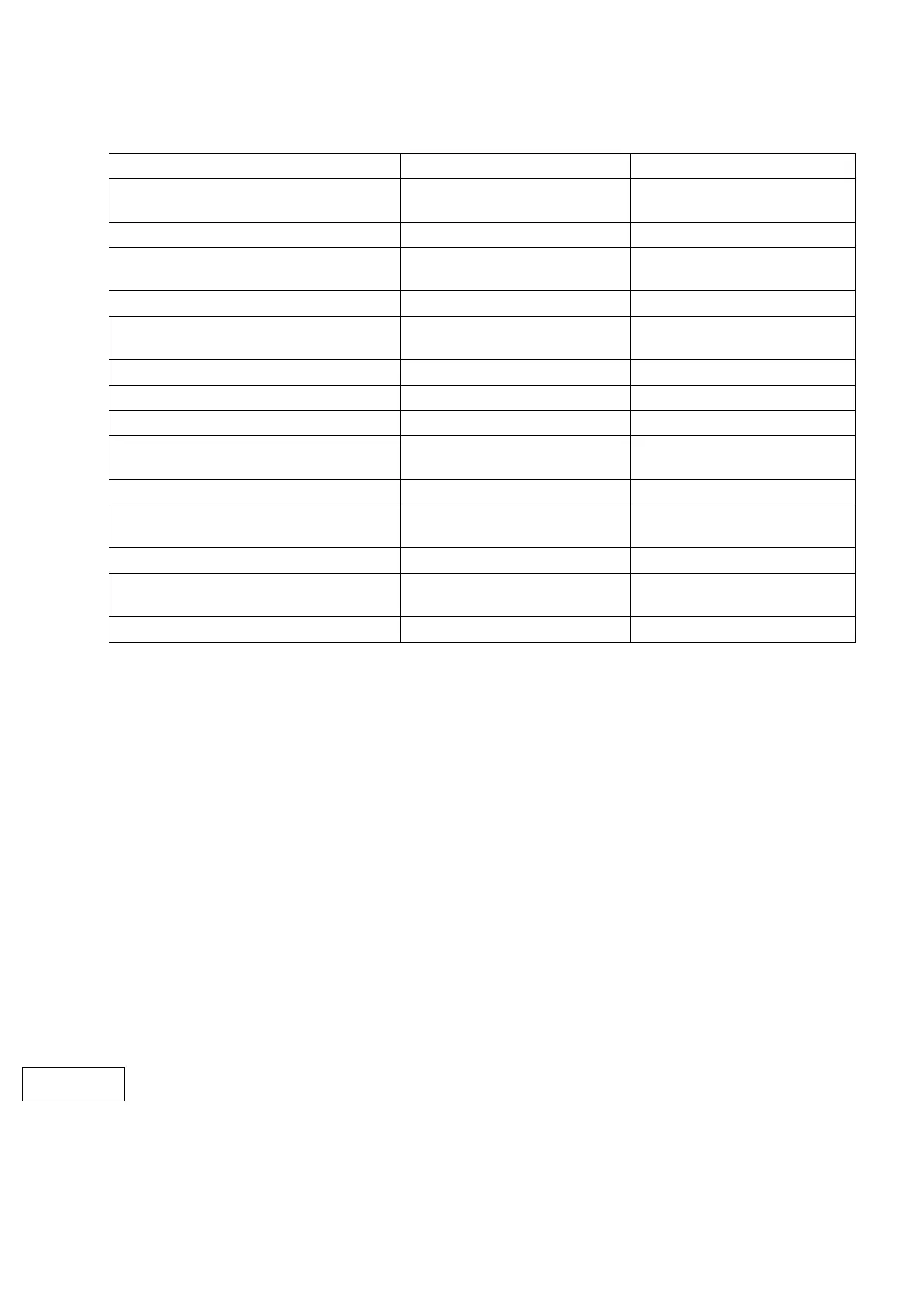

VISCOSITY LIMITS

Following viscosity limits apply to the different seal faces commonly used within

mechanical seals:

Seal face Viscosity [ cP ]

Solid Carbon Up to 5000

Silicon Carbide Up to 150000

For viscosities above 150000 cP double seals should be considered.

Note: For flush piping locations see 3.8.3

Loading...

Loading...