Page 12 of 42 pages

1.4 Zero setting by reversal measurement (Absolute ZERO)

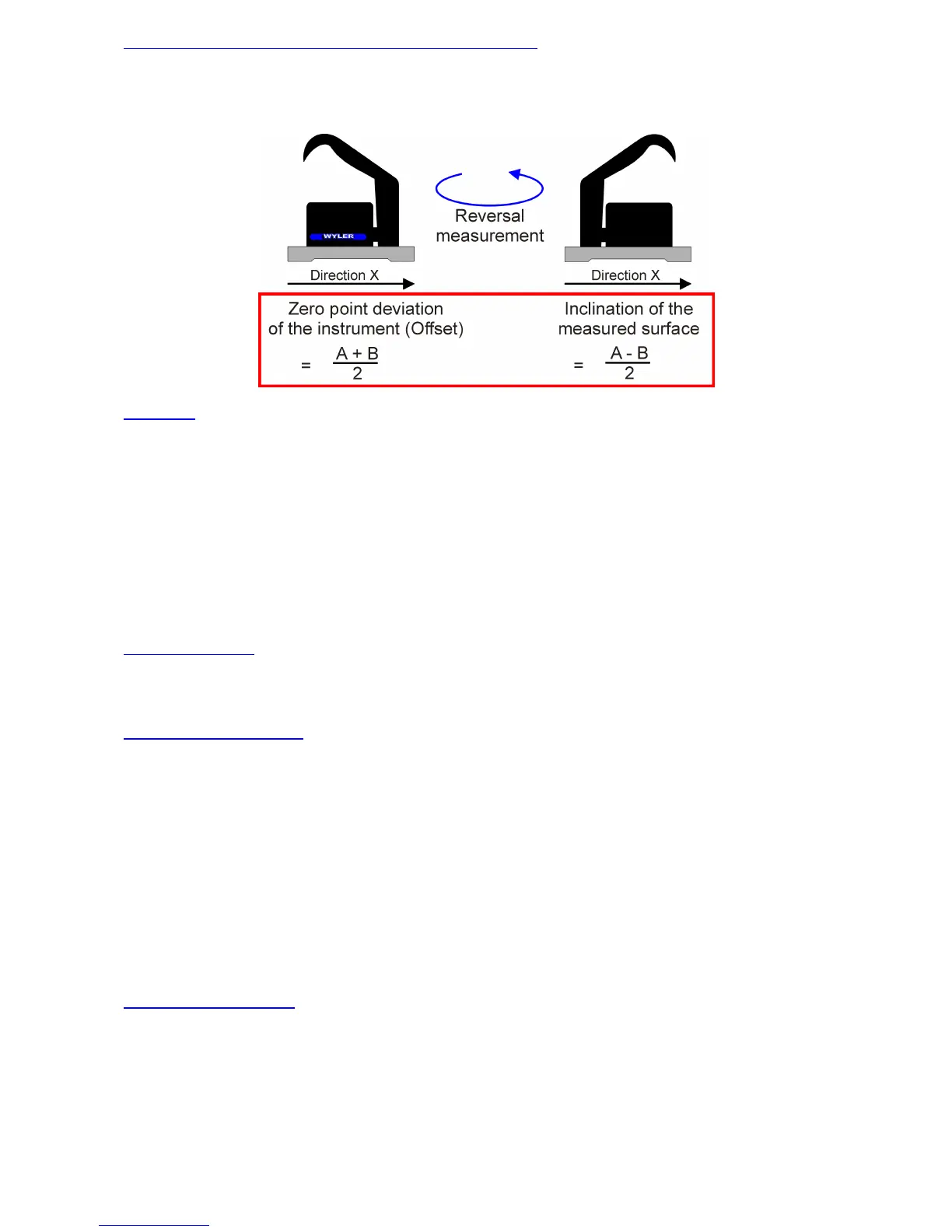

Using the reversal measurement is a simple way to determine the exact zero offset of the instrument as well as

the exact inclination of the surface the instrument is placed.

Procedure:

Prior to adjusting the zero point, the instrument should be allowed time to acquire the ambient, respectively the

work-piece temperature. Also the measuring system should have been switched on for about 1 min. (for

sensitivity of 1 mm/m about 3 minutes).

- Slide the instrument onto a flat, horizontally levelled surface (e.g. engineer's surface plate).

- The position of the MINILEVEL NT is to be marked on the surface.

- Set the display on the instrument or on the LEVELMETER to zero.

- The instrument must be turned 180 degrees and slid exactly onto the previously marked position.

- Read the value and divide by two

- Set the display on the instrument or on the LEVELMETER to the so calculated value

- Now reverse the instrument once more. The display should now show the same value as before

but with reversed indication.

1.5 Applications

The following examples are displayed by using LEVELTRONIC and LEVELMETER. Naturally the same

measurements are possible by using MINILEVEL

1.5.1 Measuring absolute

Zero point is to be set by reversal measurement. Now the LEVELTRONIC/LEVELMETER will read deviations

from absolute horizontal position.

Using MINILEVEL NT and LEVELTRONIC NT with a LEVELMETER 2000 the value of the display is shown in

Arcsec or in µm/m.

Using one of the analogue instruments MINILEVEL „classic“ / „NT“ and LEVELTRONIC „classic“ / „NT“ with

connected LEVELMETER (25 or C25/DC) then the values displayed are "digits".

The digits must be multiplied by the value stated on the handle of the LEVELTRONIC and below the LCD on the

LEVELMETER to calculate the correct inclination.

The MINILEVEL „classic“ has two measuring ranges.

Range II is the fine range. The displayed digits must be calculated by multiplying with the correct sensitivity.

Range I is the coarse range. The displayed digits must be calculated by multiplying with the correct sensitivity

and the factor 10.

1.5.2 Measuring relative

It is not always required to set the instrument to zero by reversal measurement (absolute ZERO). If e.g. the

straightness of a line is measured only the relative most of the time the relative straightness is only required.

The same applies when lines, parallels, flatness is measured with the WYLER LEVELSOFT. These are relative

measurements.

Loading...

Loading...