Page 15 of 42 pages

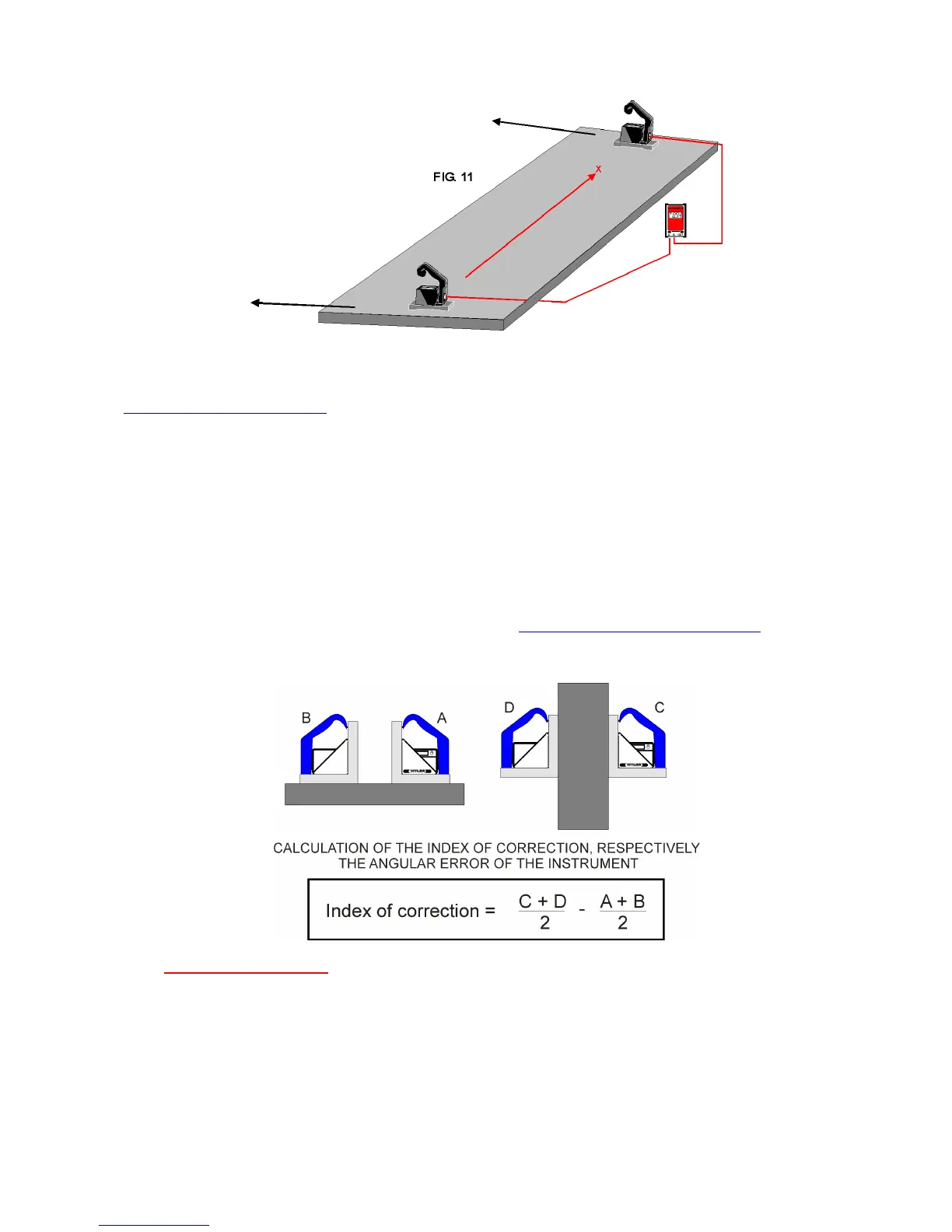

Torsion, Fig. 11

Torsion in guide ways and workpiece surfaces. The instrument (M) is moved step by step in direction of X,

noting the reading at each step after allowing sufficient time for the instrument to settle. (Attention: Measuring

axis have to be parallel!)

1.5.4 Angular measurements

a) Small angles

The measuring instruments MINILEVEL and LEVELTRONIC are especially well suited for measuring small

angles. It is however to be considered that the larger the angle is getting the larger the linearity error of the

instrument is. It is therefore important to level the object to be measured (e.g. surface plate) as good as possible

in both axis.

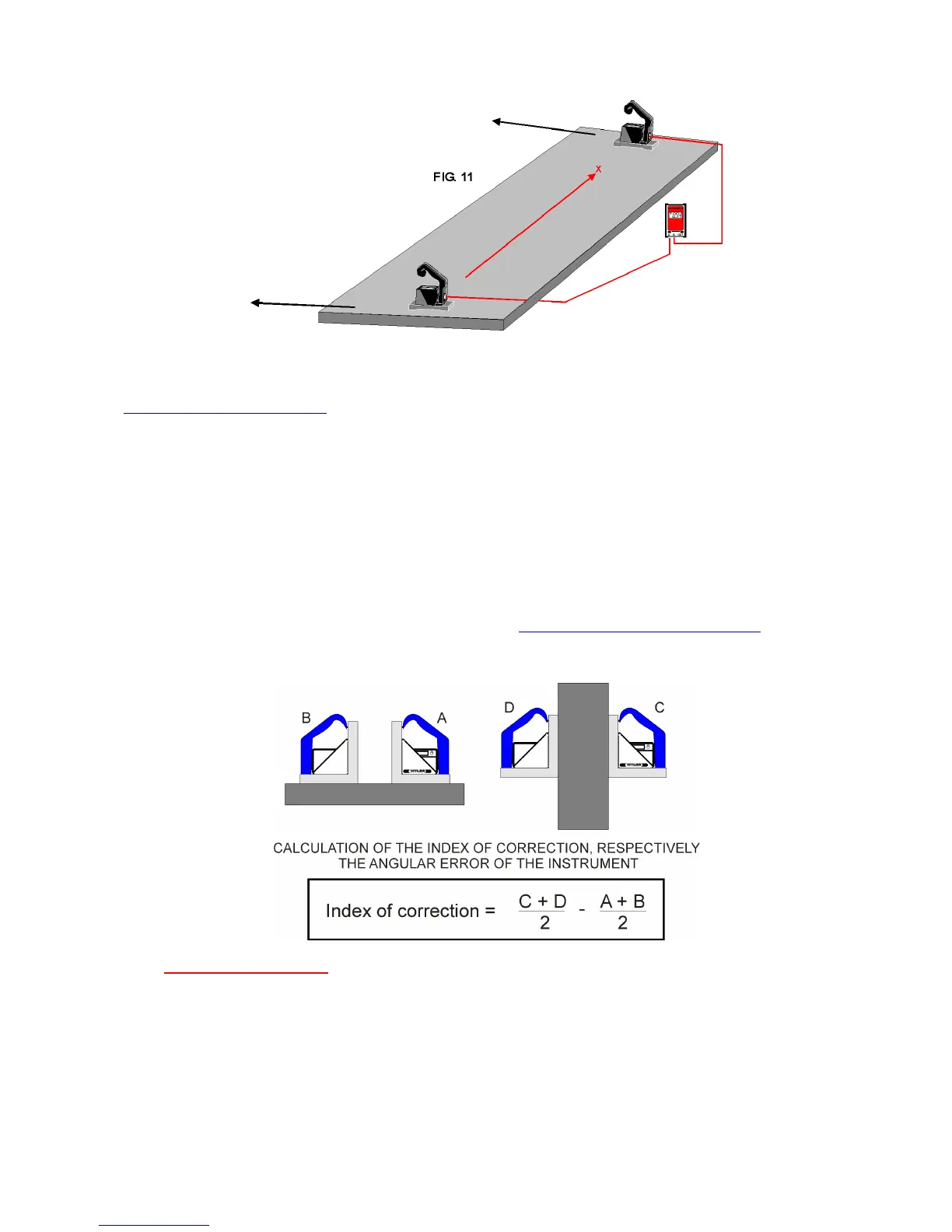

b) 90°-angle (squareness)

For measuring 90° angles (square angles) instruments with an angular base can best be used. Before starting a

precision measurement the angular error of the instrument must be determined by reversal measurement on a

suitable object.

After the reversal measurement precision measurement with measuring uncertainty of 3 to 5 µm/m

is possible.

The determination of the instrument's angular error is done as follows:

In the WYLER LEVELSOFT 99

a new set-up allows the easy measurement of squareness of rectangular

objects.

Loading...

Loading...