Page 14 of 42 pages

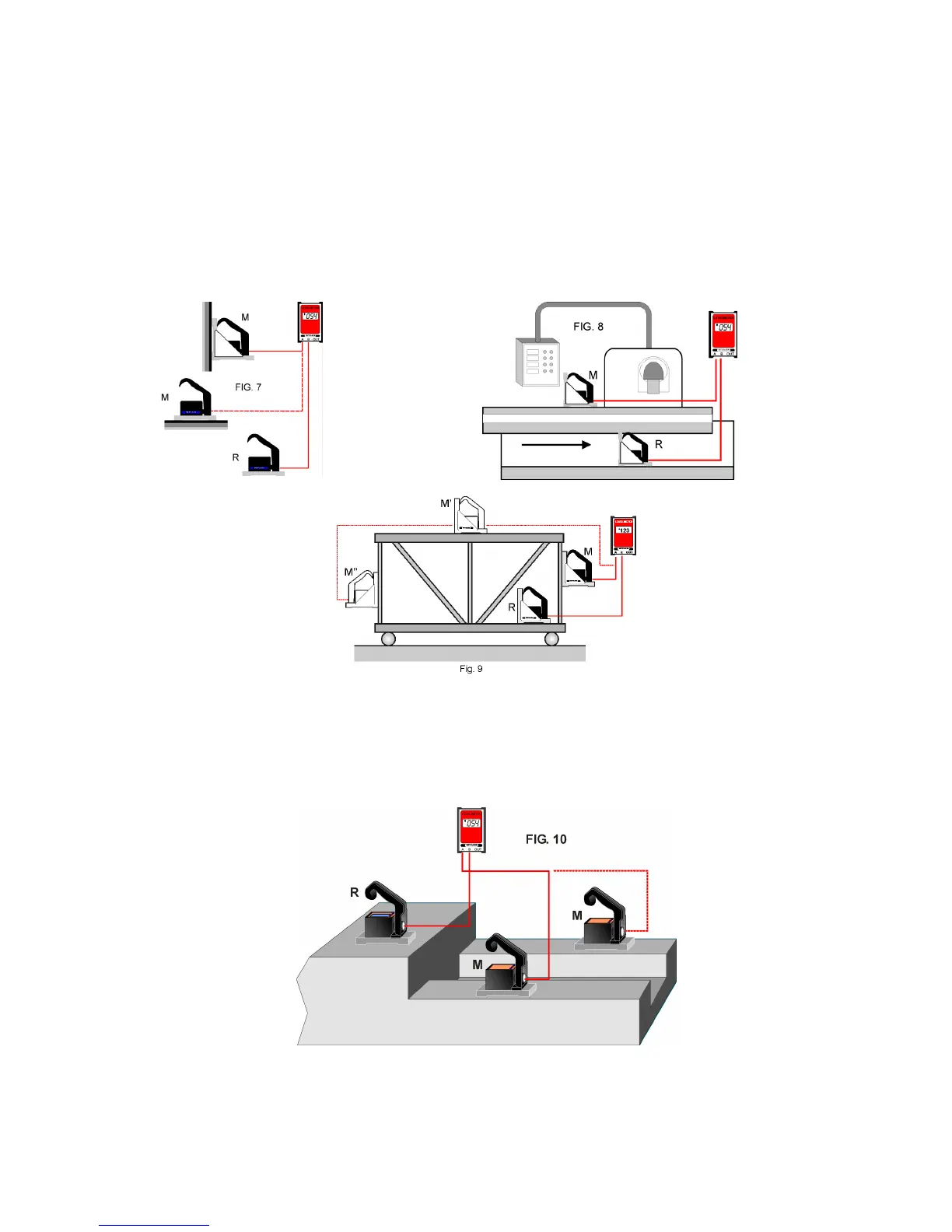

Examples for differential / reference measurement:

R = Reference instrument, connected to port „-B“

M = Measuring instrument, connected to port „A“

Fig.7

Rectangularity resp. parallelism of machine spindle in resp. to work table.

For precise square measurements an angular model fitted with magnets in the vertical face should be used.

(Elimination of deformation due to manual pressure).

Fig. 8

Straightness of table motion in relation to the machine’s base. The table must be moved step by step and the

measured value at each step should be noted/recorded after stabilization only.

Fig. 9

Inspection of perpendicularity and parallelism on large structures. Suitable instrument for outdoor applications.

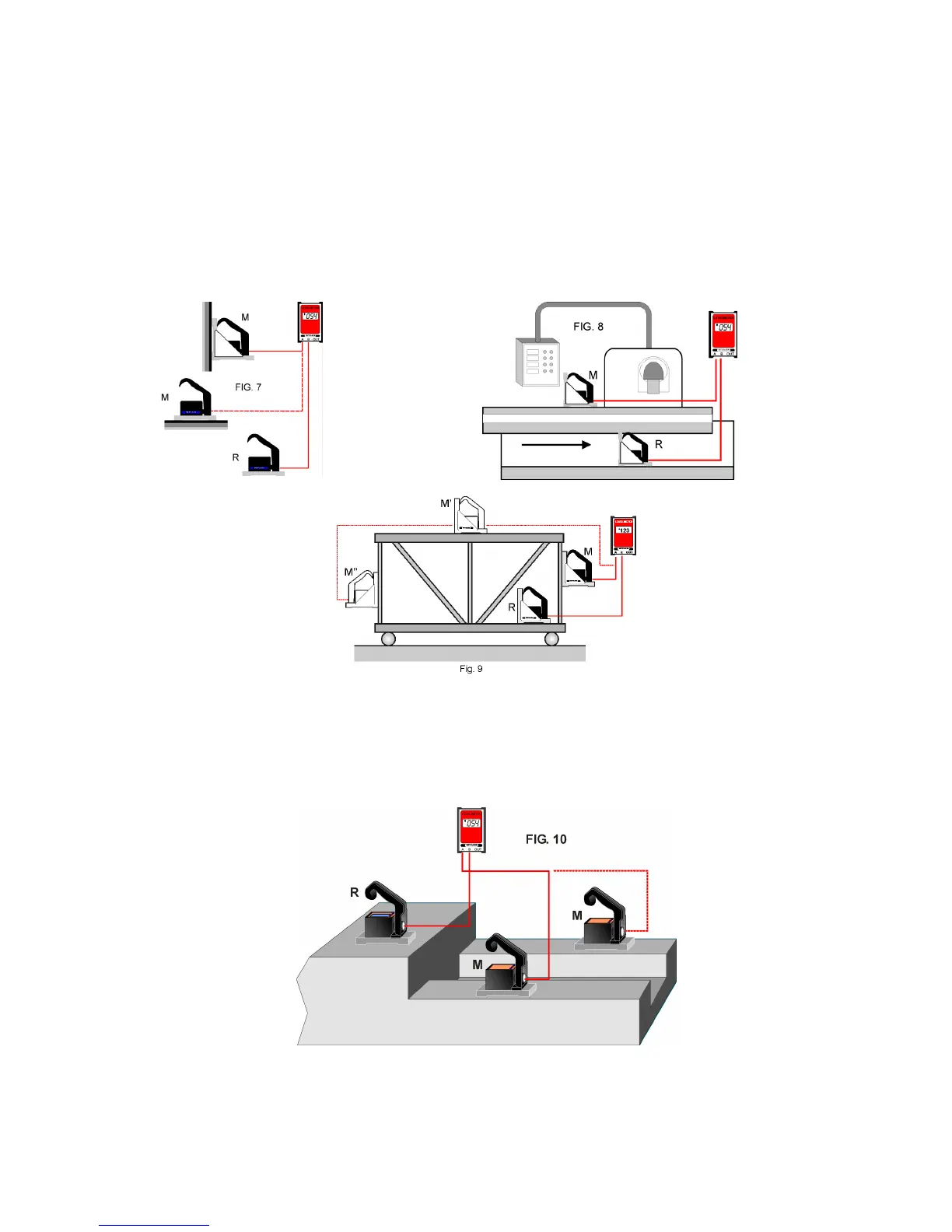

Parallelism, Fig. 10

To conduct high precision measurements of parallelism (e.g. guide way rails), measure each rail step by step

thereby following the procedure described in 3.5.

The reference LEVELTRONIC (R) will compensate for all changes in the objects orientation while

measurements are made. Using this method the instrument (sensitivities up to 1 µm/m) allows determination of

the exact shape of the guide ways.

Loading...

Loading...