3 Conditions of Acceptability

YASKAWA ELECTRIC TOBP C710606 21D YASKAWA AC Drive - V1000 Finless Installation Guide 11

Table 2 Recommended Heatsink Plate Thermal Compounds

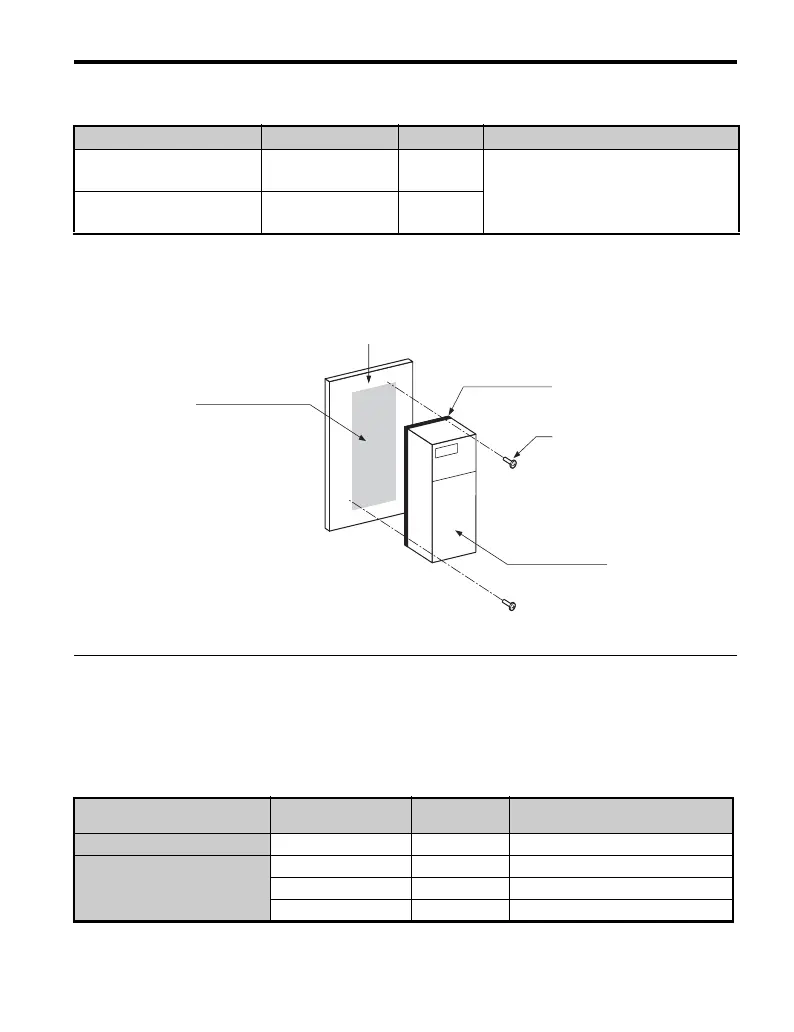

When applying the thermal compound, spread it over the surface of the heatsink plate. After

mounting the heatsink plate to the metal back panel, wipe away any excess compound from

around the heatsink plate.

Figure 3

Figure 4 Application of Thermal Compound

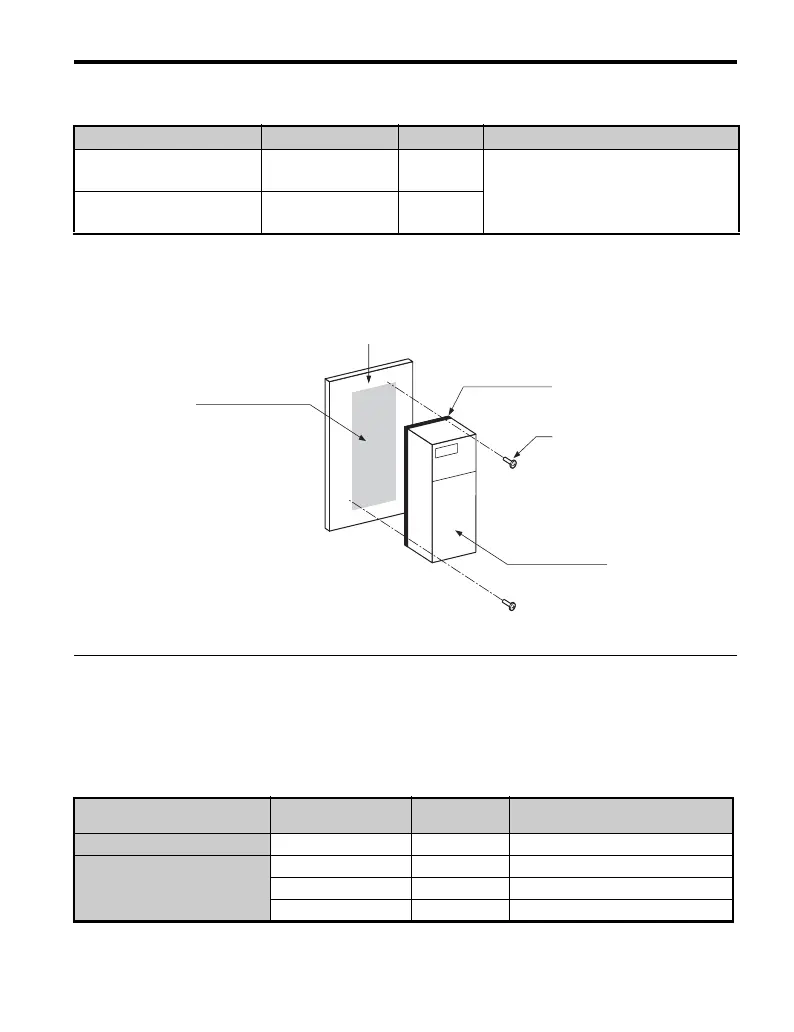

◆ Drive Heatsink Plate Installation Screw Size and Tightening

Torque

Screw size and torque specifications for heatsink plate installation screws that hold the drive

to a metal back panel are listed in Tab le 3.

Table 3 Screw Size and Tightening Torque

Manufacturer Type Model Recommended spread amount

Shin-Etsu Chemical Inc.

Oil-based

compound

G746

100 μm

Apply the coating evenly across the

surface

Dow Corning Toray Inc.

Silicone compound

for heat dissipation

SC4471CV

Voltage Class

Model

CIMR-V

Screw Size

Tightening Torque

Nxm (ft-lbf)

Single-Phase 200 V class BA0001 ~ BA0012 M4 1.0 to 1.3 (0.74 to 0.96)

Three-phase 200V class

2A0001 ~ 2A0020 M4 1.0 to 1.3 (0.74 to 0.96)

2A0030 ~ 2A0056 M5 2.0 to 2.5 (1.48 to 1.84)

2A0069 M6 4.0 to 5.0 (2.95 to 3.69)

Metal panel

Thermal compound

Heatsink plate

Installation

screws

V1000 Finless

Loading...

Loading...