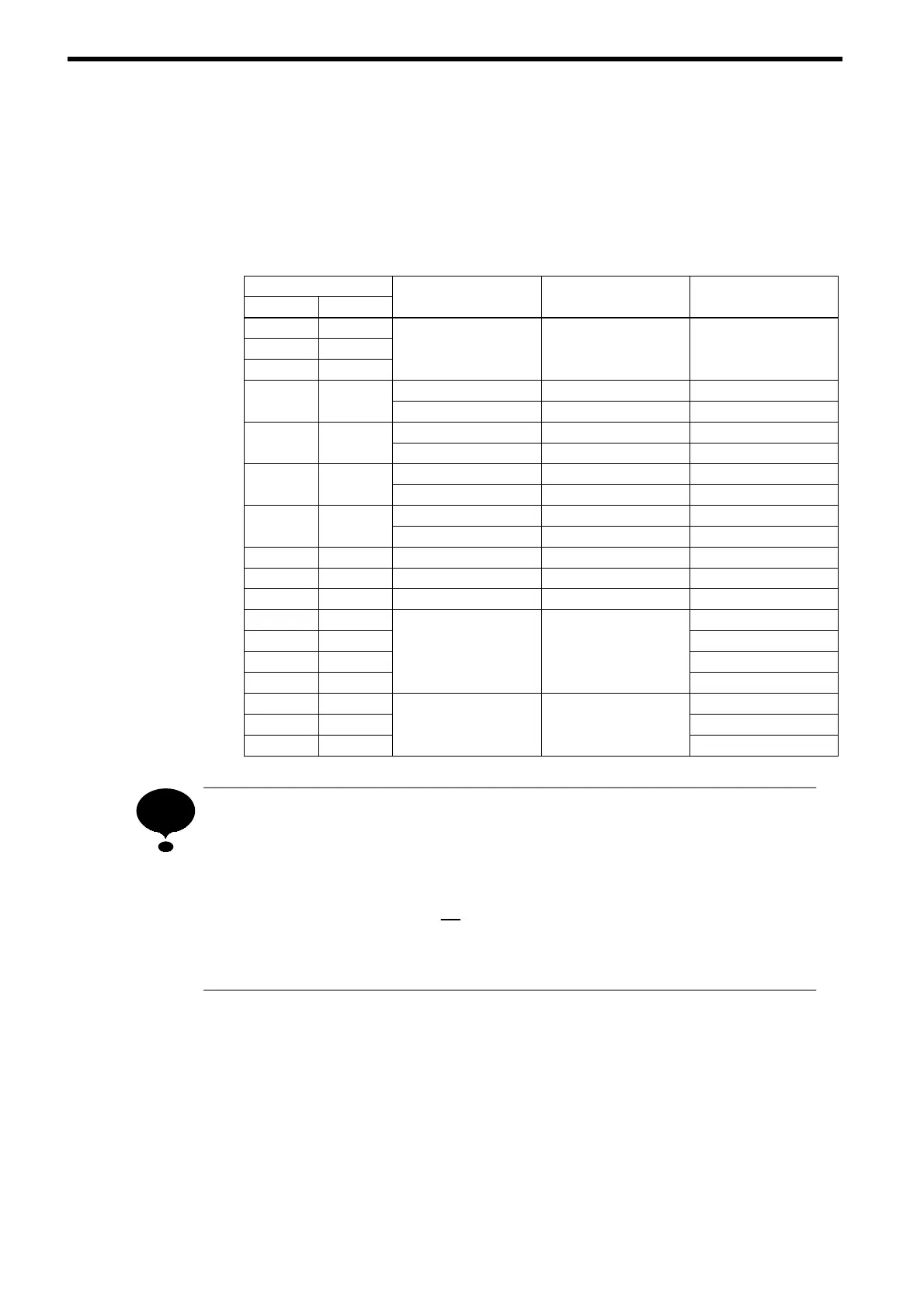

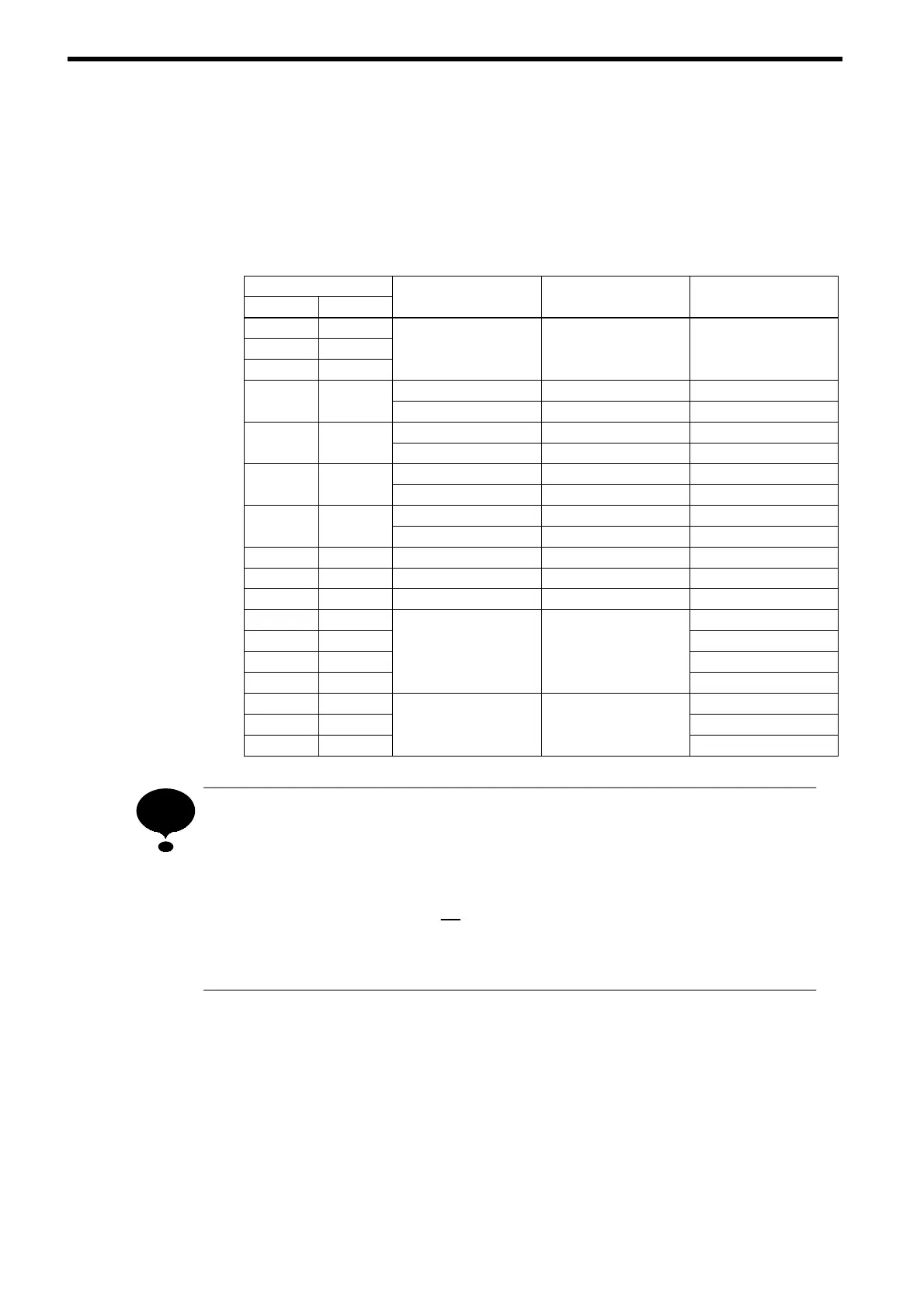

(2) Closed-Loop Connectors Size

Table 10 Closed Loop Connectors Sizes (JIS C 2805) (For 200 V/400 V classes)

Wire Size

mm

2

AWG

Terminal Screw Tightening Torque (N•m) Closed Loop Connectors

0.5 20

0.75 18

M3.5

0.8 to 1.0

1.25 to 3.5

1.25 16

.

o

.

.

o

M4 1.2 to 1.4 2to4

2 14

M5 2.1 to 2.5 2to5

M4 1.2 to 1.4 3.5 to 4

3.5 12

M5 2.1 to 2.5 3.5 to 5

M4 1.2 to 1.4 5.5 to 4

5.5 10

M5 2.1 to 2.5 5.5 to 5

M5 2.1 to 2.5 8to5

8 8

M6 3.6 to 5.1 8to6

14 6 M6 3.6 to 5.1 14 to 6

22 4 M8 8.2 to 10.2 22 to 8

30/38 3/2 M8 8.2 to 10.2 38 to 8

30/38 3/2 38 to 10

50/60 1/1/0

60 to 10

80 3/0

M10 18 to 23

80 to 10

100 4/0 100 to 10

100 4/0 100 to 12

150 300

M12 31.5 to

39.5

150 to 12

200 400 200 to 12

Determine the wire size for the main circuit so that line voltage drop is within

2 % of the rated voltage. Line voltage drop is calculated as follows:

(If there is a possibility of excessive voltage drop, use a larger wire suitable to

the required length.)

Line voltage drop (V) =

3

p

× wire resistance (Ω/km) × wire length (m) ×cur-

rent (A) × 10

-3

NOTE

32

Loading...

Loading...