<6. Operation>

57

IM 01E24A01-01EN

6. Operation

After the installation of sensor into process piping, the

wiring of input/output terminals, the conguration of

required parameters, and the zero adjustment prior to

peration, the owmeter outputs a ow signal from its

terminals as soon as the uid is sent in the pipe.

CAUTION

If any damages, such as cracks, breakage or

destruction on the glass of the display occurs, stop

using it and replace the cover. If it is used with

damaged glass, it may cause injury, electric shock,

malfunction, and specied protection performance of

the housing is not provided.

6.1 Pre-operation Zero

Adjustment

Zero adjustment is carried out to ensure that the output

for zero ow is 0% (i.e., 4 mA). Although adjustment to

zero is performed at the manufacturing plant prior to

shipment, this procedure must be carried out once again

following the installation of piping in order to match the

magnetic owmeter to its operating conditions.

This section describes the zero adjustment procedure

using the display unit. For AXFA11, read the applicable

user’s manual as listed in Table 1.1.

IMPORTANT

• Zero adjustment should be carried out before actual

operation. Note that parameter setting or change

cannot be carried out during execution of zero

adjustment (i.e., for approximately 30 seconds).

• Zero adjustment should only be carried out when

the sensor has been lled with measurement uid

and the uid velocity is completely zero by closing

the valve.

• Each time that the uid being measured is changed,

be sure to carry out zero adjustment with the new

uid.

6.2 Zero Adjustment from

Display Unit

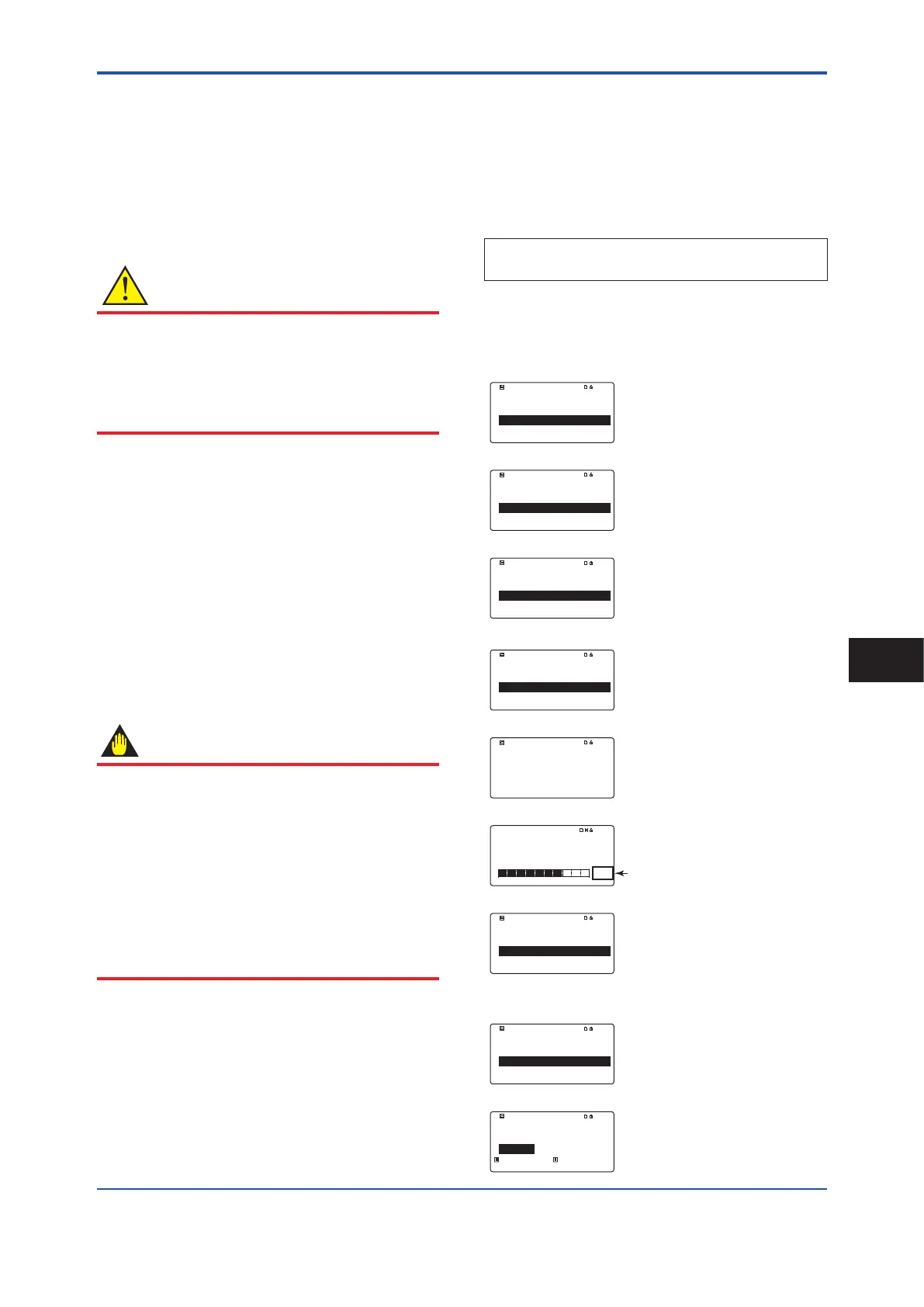

A procedure of executing zero adjustment is as follows;

Display Menu Path:

Device setup ► Diag/Service ► Autozero ► Execute

Device setup ► Diag/Service ► Autozero ► Result ► Zero value

Enter the Setting Mode. (Read Section 5.3)

For F

OUNDATION

eldbus type, set mode of all transducer

blocks to “O/S” (Out of Service) before the adjustment.

After the adjustment, set mode of all transducer blocks to

“Auto”.

Device setup

Process variables

Diag/Service

Easy setup wizard

▲

▼

SET SFT INC

►

►

►

Select “Diag/Service” accoriding to the

menu path above.

Diag/Service

Verification

Autozero

AO/AI trim

▲

▼

00 : 00

SET SFT INC

►

►

►

Select “Autozero”.

*: Fieldbus communication type does not have

AO/AI trim.

Autozero

Execute

Result

▲

▼

SET SFT INC

►

Select “Execute”.

Execute

Not execute

Execute

Not execute

▲

▼

00 : 00

SET SFT INC

Select “Execute”.

Execute

Execute

SET SFT INC

When “Execute” blinks, touch [SET] to

execute.

Autozero function

executing...

00 : 00

00 : 08

SET SFT INC

until the end.

Autozero starts, and the progress is

desplayed with a remaining time and a

bar graph. Wait for the completion.

Autozero

Execute

Result

▲

▼

SET SFT INC

►

After Autozero nished, the display

returns to “Autozero” menu.

• Conrmation of zero adjustment result

Result

Zero value

▲

▼

00 : 00

SET SFT INC

For the result of Autozero, select “Result”

and then “Zero value”.

Zero value

– 00.018cm/s

– 00.018cm/s

– 99.999 + 99.999

SET SFT INC

Result of Autozero is indicated as on

the left.

Operation

6

Loading...

Loading...