<11. CALIBRATION OF ISC (Inductive Conductivity)>

11-3

IM 12A01A02-01E 8th Edition : Oct. 01, 2015-00

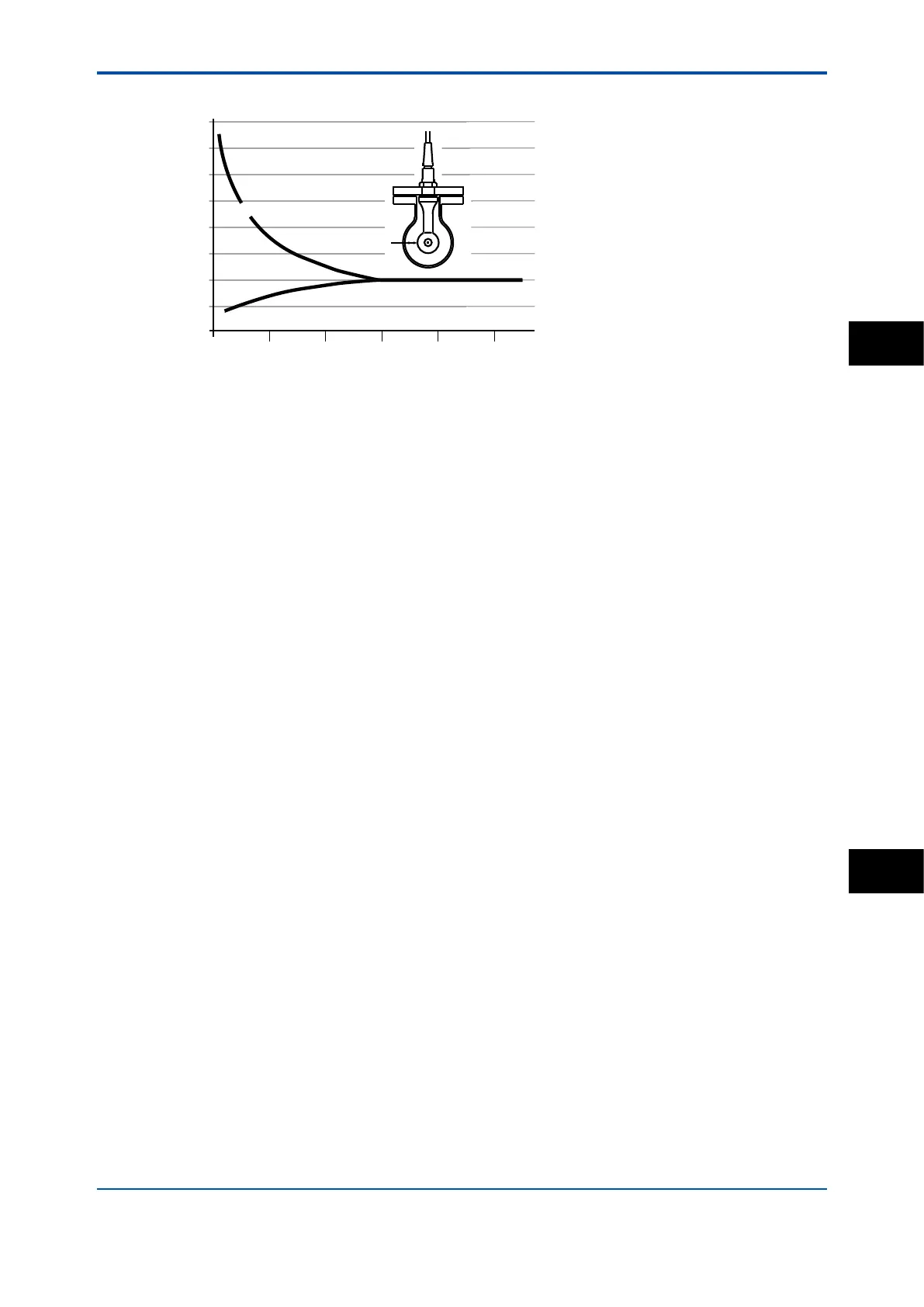

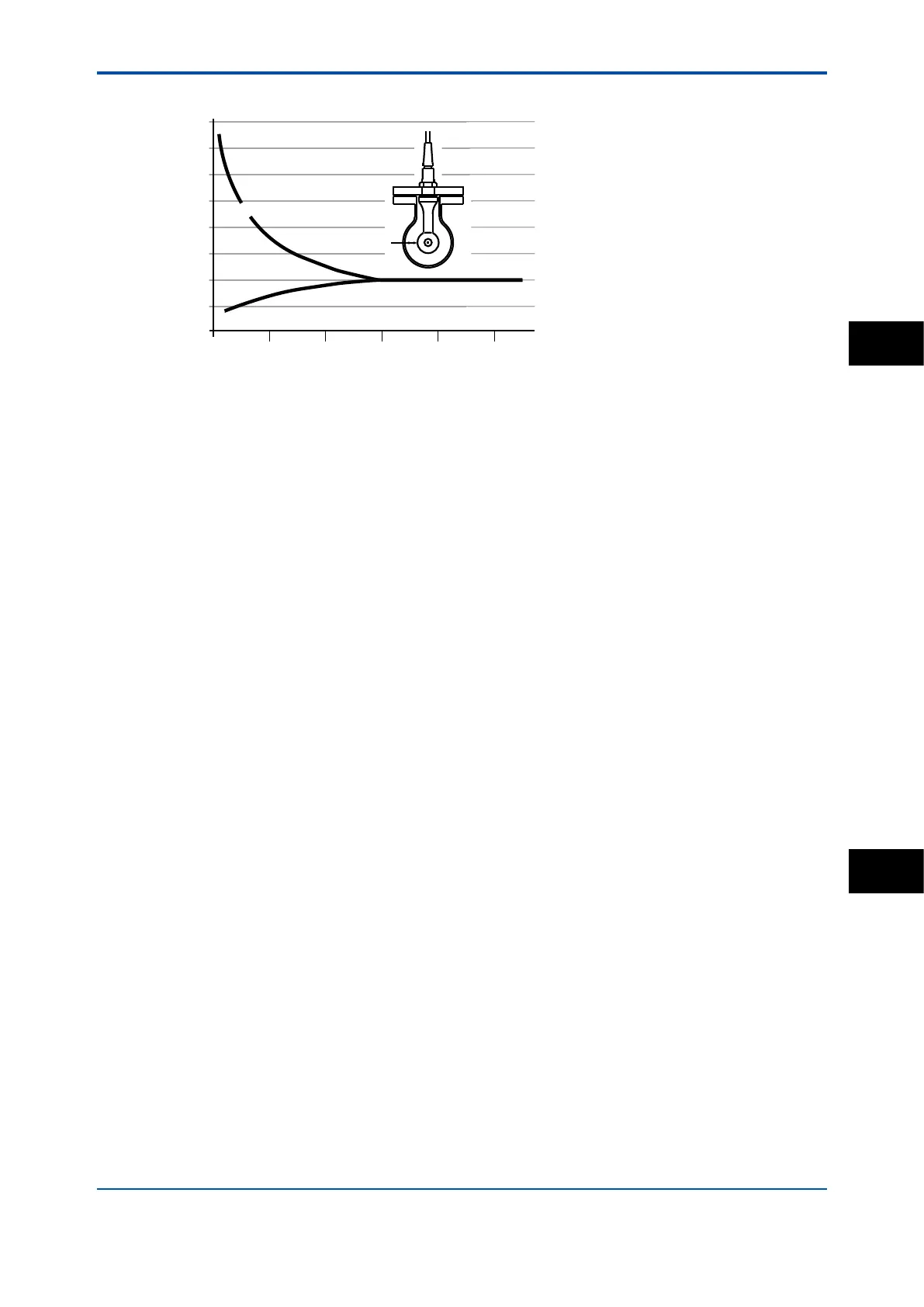

D

Non-conductive piping

Conductive piping

Distance D (mm)

0 10 20 30 40 50

0.90

Correction factor (x nominal C.C.)

0.95

1.30

1.25

1.20

1.00

1.05

1.10

1.15

Figure 11.3 Relationship between the distance from the sensor to side wall and the cell constant

11.1 Cell constant (manual)

The intention of this calibration routine is to ne-tune a sensor for which only the nominal cell

constant is known, or to recalibrate a sensor that has been changed (or damaged) during

operation. Choose the 1st or 2nd temperature compensation to suit the calibration solution used.

The solution with an appropriate precision should be prepared or purchased. Allow the sensor to

reach stable readings for both temperature and conductivity before adjusting to the value of the

corresponding calibration solution.

The cell constant of the calibrated sensor should also be set up here.

11.2 Cell constant (automatic)

This routine is built around the test method described in International Recommendation No.

56 of OIML (Organisation Internationale de Metrologie Legale). It allows the direct use of the

solutions prescribed in the test method, automatically selecting the appropriate temperature

compensation. The look-up table is used to nd an appropriate conductivity reading for the

measured temperature. See Appendix 3 for OIML solutions.

11.3 Air calibration

Execute air calibration rst, if needed.

With the clean dry cell in open air, the reading should be zero. The air cal compensates for

excess cable capacitance, and gives a better accuracy at low readings. This should be done

when a sensor is installed or replaced. After some time in service, a dirty sensor may well show

a high zero offset because of fouling. Clean the sensor and try again. Moreover, air calibration

should be made in an environment free of electromagnetic interference.

Wait for the sensor to dry because air cal must be made with no current ow in the sensor, that is,

the sensor must be dried while being exposed to air.

ISC

11

Loading...

Loading...