IM 05P01C31-15EN page 8/12

7.

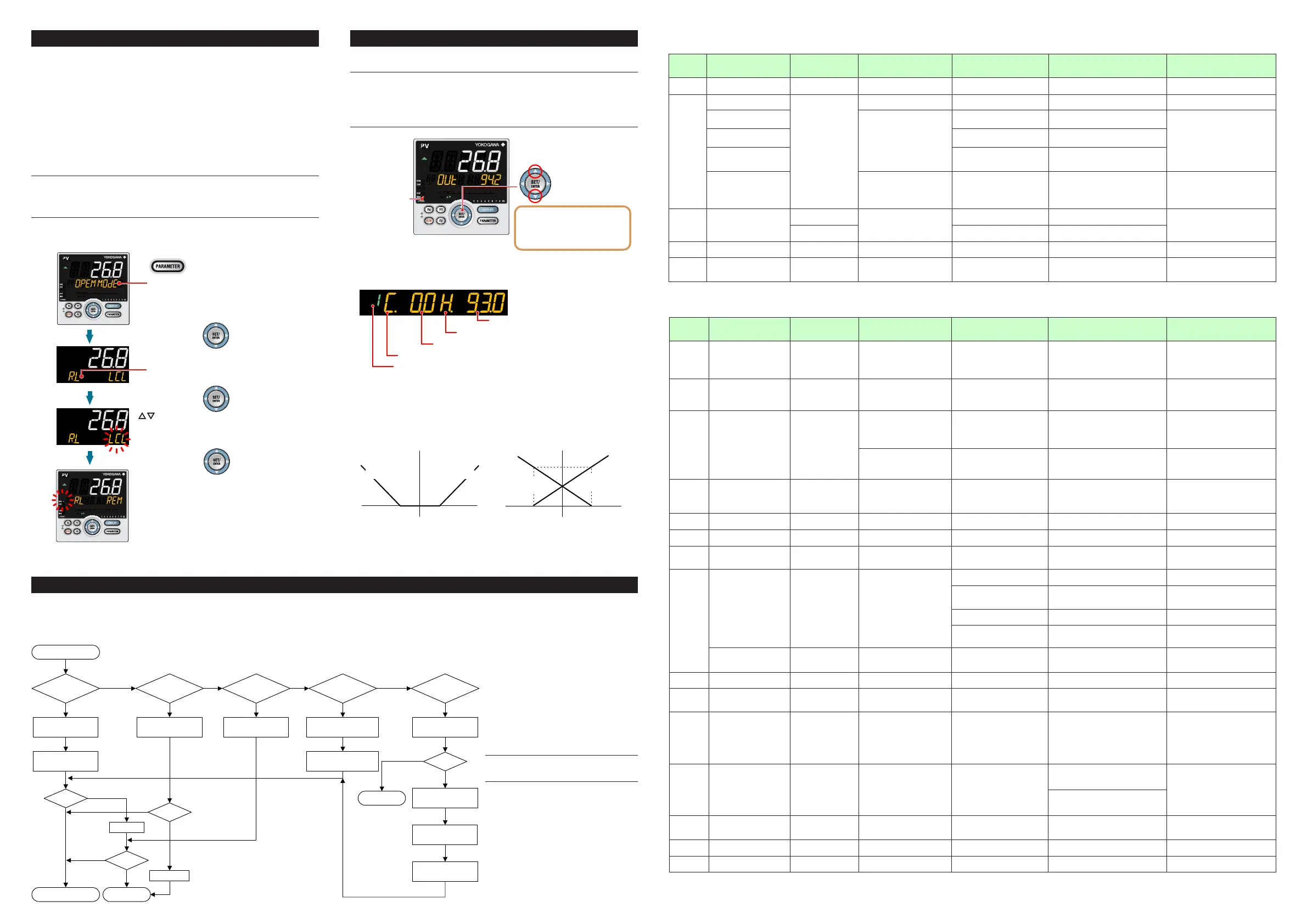

Switching between REM (Remote) and LCL (Local)

Remoteandlocalswitchingcanbeperformedusinganyofthefollowing:

(1)Contactinput,(2)Parameter,(3)Communication,and(4)Userfunctionkey.

LCL (Local)

Controlisperformedusingthetargetsetpointsetonthecontroller.

REM (Remote)

Controlisperformedusinganexternalanalogsignalthatisusedasthetargetset-

point.Thefollowingshowsan exampleofswitchingfromlocalto remoteusingthe

parameter.

Fordetailsofotherswitchingmethods,seeUser’sManual(IM05P01C31-01EN).

•ThePIDgroupforthelocalSPnumberisusedasPIDinremotemode.

NOTE

WhenthecontactinputisON,operationcannotbeperformedusingtheparameter,

communication,orkey. Whenthecontactinput isOFFandthe settingisswitched

usingtheparameter,communication,orkey, thelastswitchingoperationis per-

formed.

Show the Operation Display.

Hold down the PARAMETER key or PARA key

for 3 seconds to display MODE menu.

Press the SET/ENTER key.

Press the SET/ENTER key.

The REM lamp is lit.

Change the operation mode using

the Up/Down arrow keys.

Blinks during the change.

Press the SET/ENTER key.

The parameter R.L (REMOTE/LOCAL switch)

is displayed.

8.

Manipulating Control Output in Manual Mode

NOTE

Inmanualmode,controloutput ismanipulatedbyoperatingthekeys (thevalueis

changedusingtheUp/Downarrowkeys,thenoutputtedasitis).

EveniftheSET/ENTER keyisnotpressed, thecontroloutputvalue changesac-

cordingtothedisplayedvalue.

Instopmode(whentheSTOPlampislit),controloutputcannotbemanipulated.

MAN lamp is lit.

Up arrow key: increases control output.

Down arrow key: decreases control output.

In Position proportional control:

Up arrow key; opens the valve.

Down arrow key; closes the valve.

Output; only while pressing a key.

OUT; valve opening (0-100%)

Output manipulation in Position proportional control

is not restricted from output limiters (OH, OL).

Manual operation in Heating/cooling control

Symbol of cooling side

Target setpoint (SP) number

Symbol of heating side

Heating-side control output

Cooling-side control output

Uparrowkey:concurrently decreasescooling-sidecontroloutput andincreases

heating-sidecontroloutput.

Downarrowkey:concurrentlyincreasescooling-sidecontroloutput anddecreases

heating-sidecontroloutput.

(Eithernoneoftheheating-sideand cooling-sideoutputsarepresented,orboth of

themarepresentedaccordingtothedeadbandsetting.)

DB=24.8

Dead band: Operation parameter DB

Control computation output Control computation output

12.40-12.4

Manipulated output change

when a dead band is positive (+)

Actual output (%)

100

DB= -24.8

12.40-12.4

Manipulated output change

when a dead band is negative (-)

100

Cooling-side

manipulated output

Heating-side

Heating-side

manipulated output

Cooling-side

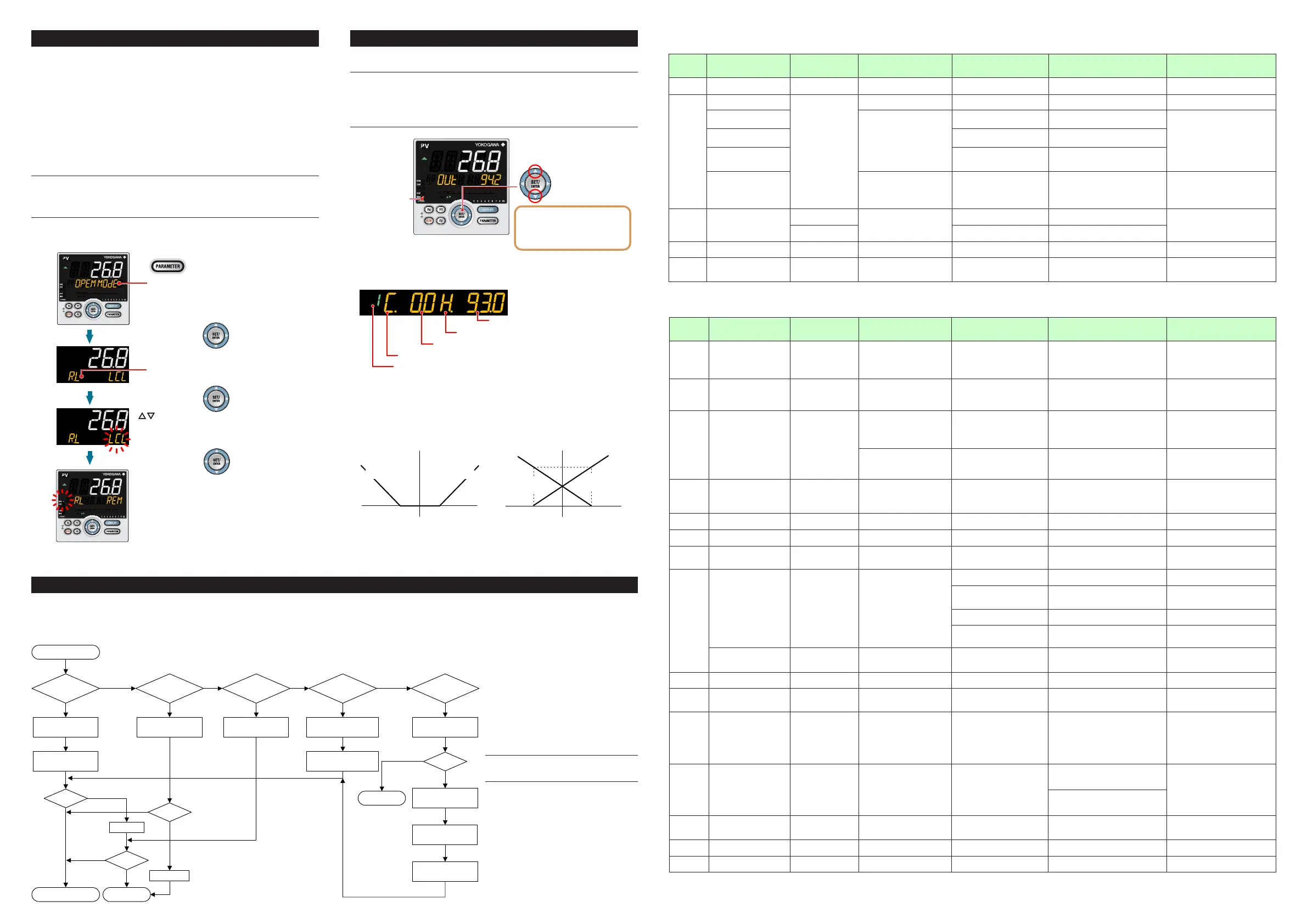

9. Troubleshooting

■TroubleshootingFlow

IftheOperationDisplaydoesnotappearafterturningonthecontroller’spower,checktheproceduresinthefollowingowchart.

Ifaproblemappearstobecomplicated,contactoursalesrepresentatives.

defective?

Contact us for repair.

Problem solved.

No communication

capability

Completely

inactive?

Yes

Yes

Yes

No

No

No

Key

operation

failure?

Yes

No

Yes

Check wiring of the

power terminals.

Check the key lock

setting.

Display

failure?

*

Yes

No

Turn off power, and

then turn it on again.

I/O signal

failure?

Yes

No

Check the

supply voltage.

Check the

specifications and polarity

of connected devices .

Check the communication-

related parameters.

Check the specifications

of communication

devices.

Check the

communication wiring.

Communication

failure?

No

With

communi-

cation?

Yes

Yes

Normal?

Is the

key locked?

Check the specifications

of the controller.

Yes

No

Correct?

Correct the error(s).

Cancel the setting.

Check the I/O specifications

of the controller.

* The LCD (a liquid crystal display) is used for

a display portion of this product.

The LCD has a characteristic that the display action

becomes late at the low temperature.

Additionally, the luminance and contrast degradation

are caused due to aged deterioration.

However, the control function is not affected.

■

Remedies if Power Failure Occurs

during Operations

• Instantaneouspowerfailurewithin20ms.

Apowerfailureisnotdetected. Normal

operation continues.

• Powerfailureforlessthanabout5seconds,

orforabout5secondsormore.

Affectsthe"settings"and"operationsta-

tus."

Fordetails,seeUser's Manual(IM

05P01C31-01EN).

NOTE

Writedownthesettingsof parametersfora

repairrequest.

n

Errors at Power On

Theerrorsshownbelowmayoccurinthefaultdiagnosiswhenthepoweristurnedon.(FordetailsofSetpointdisplayandinput/outputactionwheneacherroroccurs,seeUser’sManual(IM05P01C31-01EN).

PV display

(Operation

Display)

Setpoint display

(Operation Display)

Status indicator

(Operation Display)

Parameter that displays error

details

Error description Cause and diagnosis Remedy

Indication off Indication off — — FaultyMCURAM/MCUROM MCURAM/MCUROMarefailed. Faulty.Contactusforrepair.

ERR

SYS-----

—

— System data error System data is corrupted. Faulty.Contactusforrepair.

PAR0004

(foruserdefaultvalueerroronly)

Setupparameter(PA.ER)

User(parameter)defaultvalueerror

Userparameteriscorrupted.

Initializedtofactorydefaultvalue.

Checkandreconguretheinitialized

settingparameters.Errorindicationis

erased when the power is turned on

again.

PAR0010

(forsetupparametererroronly)

Setup parameter error

Setup parameter data is corrupted.

Initializedtouserdefaultvalue.

PAR0020

(foroperationparametererror

only)

Operationparametererror

Operationparameterdataiscorrupted.

Initializedtouserdefaultvalue.

SLOT0017

(0017:Erroroccurstoall

hardwareofE1toE4-terminal

areas.)

Setupparameter(OP.ER)

Nonrespondinghardwareof

extendedfunction(E1toE4-

terminalareas)

Inconsistence of system data and

hardwareofextendedfunction.

Nonrespondingcommunicationbetween

hardwareofextendedfunction(E1toE4-

terminalareas).

Faulty.

Contactusforrepair.

Normal

indication

Normalindication

Rightmostdecimalpoint

onPVdisplayblinks.

Setupparameter(PA.ER)

Calibrationvalueerror

Initializedtocalibrateddefaultvaluebecause

ofcorruptedfactorydefaultvalue.

Faulty.Contactusforrepair.

Rightmostdecimalpoint

onSymboldisplayblinks.

FaultyFRAM

Datawriting(storing)toFRAMis

impossible.

Normal

indication

Normalindication LADDERlampblinks Setupparameter(LA.ER) Corruptedladderprogram

Ladderprogramiscorrupted.

Operateswithoutladderprogram.

Downloadtheladderprogramagain.

Normal

indication

0.00000000

(Decimalpointontheleftof

theSymboldisplayblinks)

— Setupparameter(OP.ER) Userproleerror Userproleiscorrupted. Downloadtheuserproleagain.

n

Errors during Operation

Theerrorsshownbelowmayoccurduringoperation.(Forinput/outputactionwheneacherroroccurs,seeUser’sManual(IM05P01C31-01EN).

PV display

(Operation

Display)

Setpoint display

(Operation Display)

Status indicator

(Operation Display)

Parameter that displays

error details

Error description Cause and diagnosis Remedy

AD.ERR

Normalindication(Note) — Setupparameter(AD1.E)

AnaloginputterminalADCerror

•PVinput

•RSPinput(E1-terminalarea)

•AIN2input(E2-terminalarea)

•AIN4input(E4-terminalarea)

AnaloginputterminalADvalueerror

Faulty.

Contactusforrepair.

RJC.E

(DisplaysRJC.

EandPV

alternately.)

Normalindication(Note) — Setupparameter(AD1.E)

UniversalinputterminalRJCerror

•PVinput

•RSPinput(E1-terminalarea)

UniversalinputterminalRJCerror

Faulty.

Contactusforrepair.

SettheparameterRJCtoOFFtoerase

error indication.

B.OUT

Normalindication(Note) —

Setupparameter(AD1.E)

Analoginputterminalburnouterror

•PVinput

•RSPinput(E1-terminalarea)

•AIN2input(E2-terminalarea)

•AIN4input(E4-terminalarea)

Analoginputterminalsensorburnout

Checkwiringandsensor.

Errorindicationiserasedinnormal

operation.

Setupparameter(PV1.E/PV2.E)

PVinputburnouterror(Loop1,

Loop2)

BurnoutofanaloginputconnectedtoPV

Checkwiringandsensorofconnected

analoginputterminals.

Errorindicationiserasedinnormal

operation.

OVER

-OVER

Normalindication — Setupparameter(PV1.E/PV2.E)

PVinputover-scale

PVinputunder-scale

(PVvaluesoutof-5to105%)(Loop

1,Loop2)

PVinputisoutof-5to105%.Alsooccurs

whenthedataoutofrangewhichisthe

ladder calculation result is input.

Checkanaloginputvalueorladder

program.

Normal

indication

Normalindication — Setupparameter(PV1.E/PV2.E)

RSPinputburnouterror(Loop1,

Loop2)

BurnoutofanaloginputconnectedtoRSP

Checkwiringandsensor.Error

indication is erased in normal operation.

Normal

indication

RSPB.OUT

— Setupparameter(PV1.E/PV2.E)

BurnouterrorwhenRSPinputis

usedforcontrol(Loop1,Loop2)

BurnoutofanaloginputconnectedtoRSP

whenRSPisusedforcontrolcomputation

Checkwiringandsensor.Error

indication is erased in normal operation.

Normal

indication

OUT-----

— Setupparameter(AD2.E)

Feedbackinputresistor/current

burnout

Feedbackinputburnout

Checkwiringoffeedbackinputresistor/

current.Errorindicationiserasedin

normal operation.

Normal

indication

Normalindication LADDERlampblinks Setupparameter(LA.ER)

Laddercalculationoverow

Floatingpointcomputationforladder

calculationisinnite.

Checktheladderprogram.

Loadfactorover100%

Computationdoesnotendwithinthe

controlperiod(loadfactoris100%or

more).

Changethecontrolperiodorreduce

thenumberofstepsfortheladder

program.

Loadfactorover200%

(Forcedend)

Computationdoesnotendwithinthecontrol

period(loadfactoris200%ormore).

Changethecontrolperiodorreducethe

numberofstepsfortheladderprogram.

Ladderprogramerror Ladderprogramiscorrupted.

Downloadtheladderprogramagain.If

theerrorindicationisstillnoterased,

thereisafault.Contactusforrepair.

0.00000000

(Decimalpointontheleftof

theSymboldisplayblinks)

— Setupparameter(OP.ER) Peer-to-peercommunicationerror Peer-to-peercommunicationerror

Checkthatthetargetdevicesare

connected correctly.

Recoveryatnormalreceipt.

AT.E

Normalindication — Setupparameter(PV1.E/PV2.E)

Auto-tuningtime-out

(Loop1,Loop2)

Auto-tuningdoesnotendevenwhen24

hourshaveelapsedafterthestartoftuning.

Checktheprocess.Holddownanykeyto

erase the error indication

VAT.E

Normalindication — Setupparameter(AD2.E)

Valvepositionautomatic

adjustmenterror

Fully-closedvalvepositionisequaltoorlarger

thanthefully-openvalvepositionafterautomatic

valvepositionadjustmentisperformed.

Checkwiringandvalve.Holddownany

key to erase the error indication.

Normal

indication

0.00000000

(Decimalpointontheleftof

theSymboldisplayblinks)

— Setupparameter(OP.ER)

Communicationerror

(RS-485communication)

Framingparityerror

Bufferoverow

Inter-charactertime-out

Checksumerror(PClinkcommunicationwith

checksum)

CRCcheckerror(Modbus/RTU)

LRCcheckerror(Modbus/ASCII)

Checkthecommunicationparameters.

Recoveryatnormalreceipt.

Holddownanykeytostopblinking.

Normal

indication

0.00000000

(Decimalpointontheleftof

theSymboldisplayblinks)

— Setupparameter(OP.ER)

Communicationerror

(coordinatedoperation)

Inconsistenceofloopbetweencoordinated

masterandslaves

Checkthecommunicationparameters.

Recoveryatnormalreceipt.

Changefromremotetolocalmodetostop

blinking.

Whenthemodeischangedfromremoteto

local,SPtrackingdoesnotworkevenifitis

settoON.

Communicationfromcoordinatedmasteris

interrupted for 2 seconds.

Normal

indication

0.00000000

(Decimalpointontheleftof

theSymboldisplayblinks)

— Setupparameter(OP.ER) Userproleerror Userproleiscorrupted. Downloadtheuserproleagain.

Normal

indication

Normalindication

Rightmostdecimalpointon

Symboldisplayblinks.

Setupparameter(PA.ER) FaultyFRAM

Writing(storing)datatoFRAMisimpossible.

Faulty.Contactusforrepair.

Undened Undened — —

FaultyMCU/DCU

(ROM/RAMerror,corrupted)

MCU/DCUiscorrupted. Faulty.Contactusforrepair.

Note:WhenanerroroccursininputshowninAnaloginputdisplay(Operationdisplay),SetpointdisplayshowsthesamesymbolasthePVdisplay.

Loading...

Loading...