IM 01B08B02-01EN

Introduction to Functions

7

Introduction to Functions

The YS1000 series is a series of single-loop controllers to meet the demands of users’ consistently advancing and diversifying

needs. It is capable of the flexible control computation required for process control.

Features

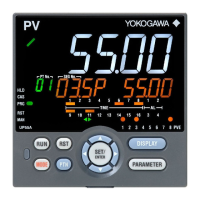

• Color LCD display

The monitoring and operation display is provided in color, and input and output values, various constants, and incorporated

control functions can be set freely using key switches on the front panel. The monitoring displays include LOOP Display,

TREND Display, ALARM Display, and METER Display which provides information in much the same way as analog meters.

• Failsafe function

Two CPUs are configured to provide manual operations and displays even if one of the CPUs becomes faulty. Moreover, be-

cause the instrument incorporates a hard manual circuit independent of the digital circuit, it can continue to generate manipu-

lated output variables even if the digital circuit that includes the CPUs fails.

• AC/DC-common power supply with wide operating voltage range.

The instrument can be powered by either AC (100 V AC) or DC (24 V DC).

• The front panel is dust- and water-proof (conforming to IP54).

• Abundant communication functions

The instrument can incorporate Ethernet (Modbus/TCP) communication, serial communication (Modbus, PC-link, and YS

protocol), and DCS-LCS communication.

• Control functions and abundant computation functions

The instrument is capable of single-loop, cascade, selector, and programmable control functions.

It can also perform computations such as the four arithmetic operations, logic computation, exponent, logarithm, temperature

compensation, pressure correction, etc. and peer-to-peer communication. (Optional YSS1000 Setting Software is required.)

• Number of I/O points

Use of YS1700’s expandable I/O terminal allows the use of a maximum of eight analog inputs, a maximum of four analog

outputs, and a maximum of 14 DIOs.

Definition of Terms

• PV: Process variable input from process

• SV: Setpoint regarded as a control target

• MV: Manipulated variable for operating control elements such as valves.

• PID control: Control system based on action which combined three elements: proportional (P) action, integral (I) action, and

derivative (D) action.

• M mode: Mode in which manipulated output variables are operated manually.

• A mode: Mode in which MV is automatically controlled based on YS1000’s setpoint

• C mode: Mode in which MV is controlled based on an external setpoint

• Multi-function mode: Modes of the three preinstalled functions (single-loop mode, cascade mode, and selector mode)

• Programmable mode: Mode in which input/output or control computation is programmed

• User program: A program created using the YSS1000 Setting Software (available as an option)

Loading...

Loading...