5.2.1 Assembly notes for cable glands

Correct use of the cable glands is of crucial importance for high operational reliability; note the

following instructions.

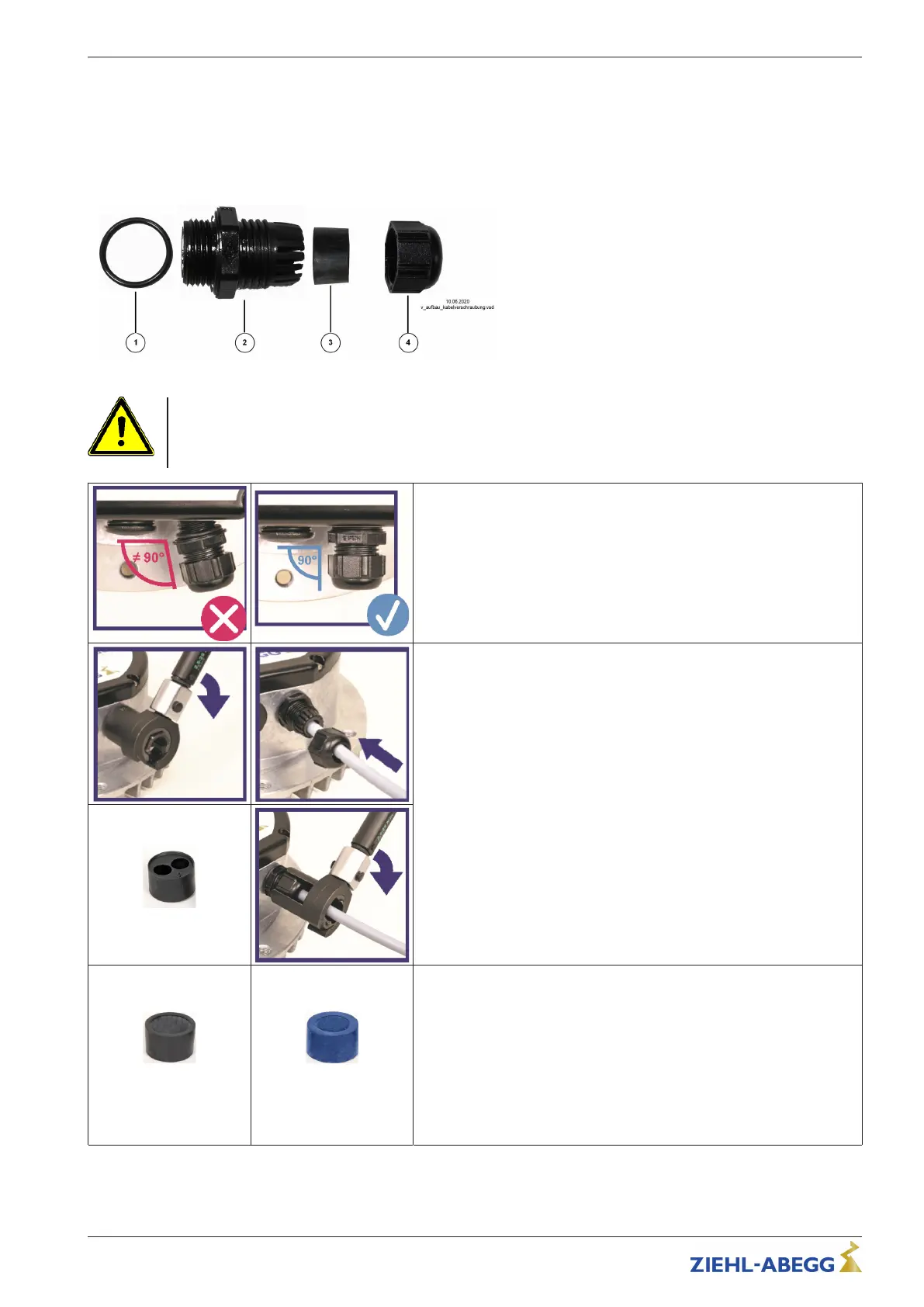

Construction of a cable gland

1. O-ring

2. Collar with connecting thread

3. seal insert

4. Union nut

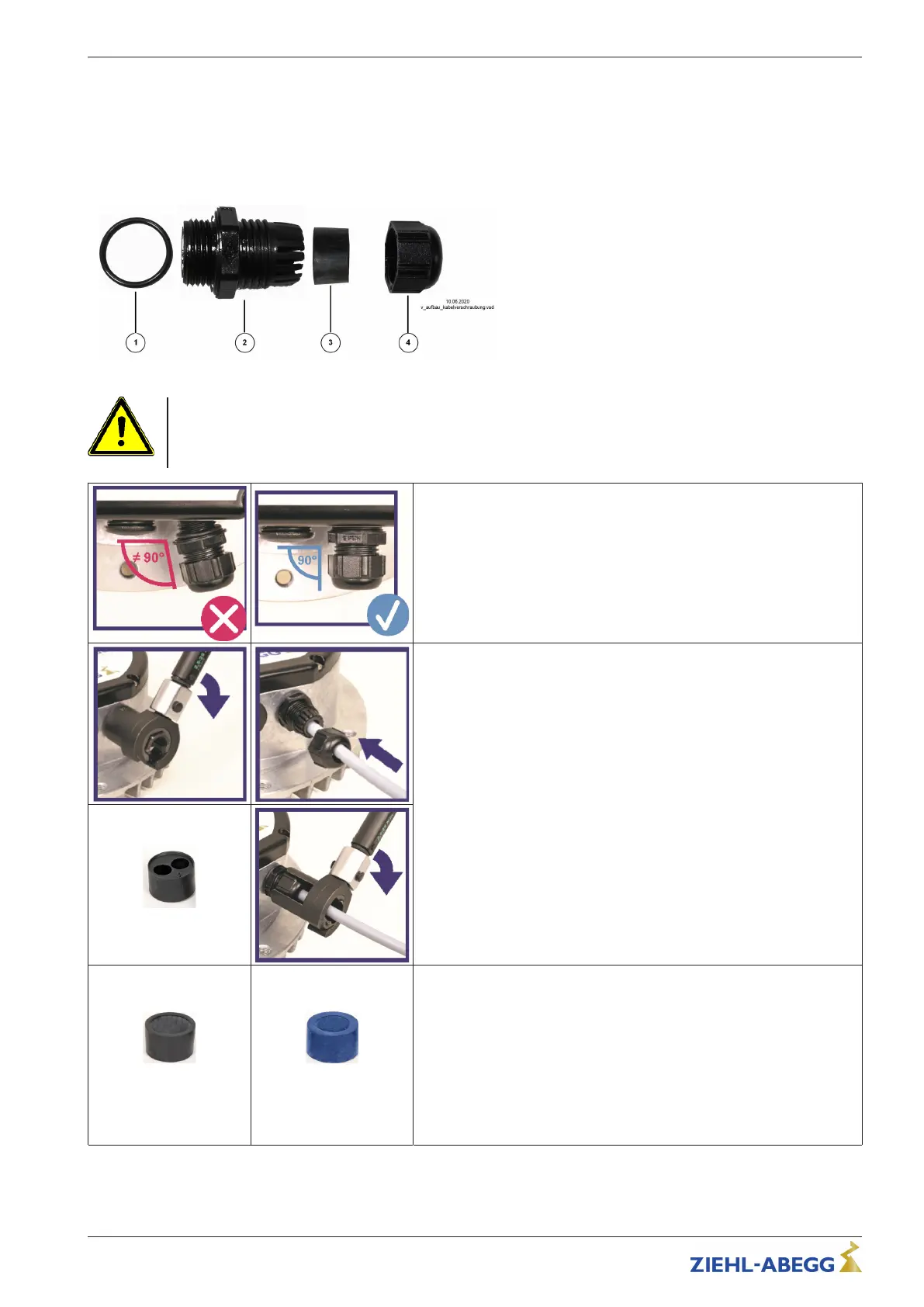

Attention!

If the tightening torque of the cable gland is too low or too high, this prevents the O-ring from having

sufficient contact with the housing and the seal insert on the cable. This results in leaks and/or poor

strain relief on the cables.

Fitting cable glands

" Select the size of the cable gland and the seal insert to match the

outer diameter of the cable.

" Check the housing for damage in the area of the sealing surface

before installing the cable gland.

" Ensure that the O-ring and seal insert are fi tted.

" Place the cable gland at a right angle on the housing and screw in.

Inserting the cable, tightening method

" Tighten the collar to the specified torque with a suitable torque

wrench.

" Insert the cable through the cable gland into the housing.

" Fit the union nut by hand and tighten slightly.

" Tighten the union nut to the specified torque of the cable gland using

the torque wrench.

" To insert two cables through one cable gland, use a seal insert with 2

boreholes.

" The seal insert supplied can only be used for a limited range of cable

diameters. It is also possible to use seal inserts with a different inner

diameter.

Seal insert for 2 cables

2 x black

Sealing area 8…12 mm

1 x blue

Sealing area 6…7.9 mm

Special feature of motor size“G” (152)

" As delivered, the 3 enclosed cable glands are fitted with one black

seal insert and two blue seal inserts.

" In addition, two black and one blue seal inserts are included sepa-

rately, and can be used if required.

Sealing areas

Black seal insert: For cables with 8…12 mm outer diameterBlue seal

insert: For cables with 6…7.9 mm outer diameter

Quick Start Guide ECblue BASIC-MODBUS, ECblue BASIC Electrical installation

L-BAL-F078-GB 2024 Index 005 Part.-No. 00706648-GB

13/32

Loading...

Loading...