©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection.

48

2. Hotend

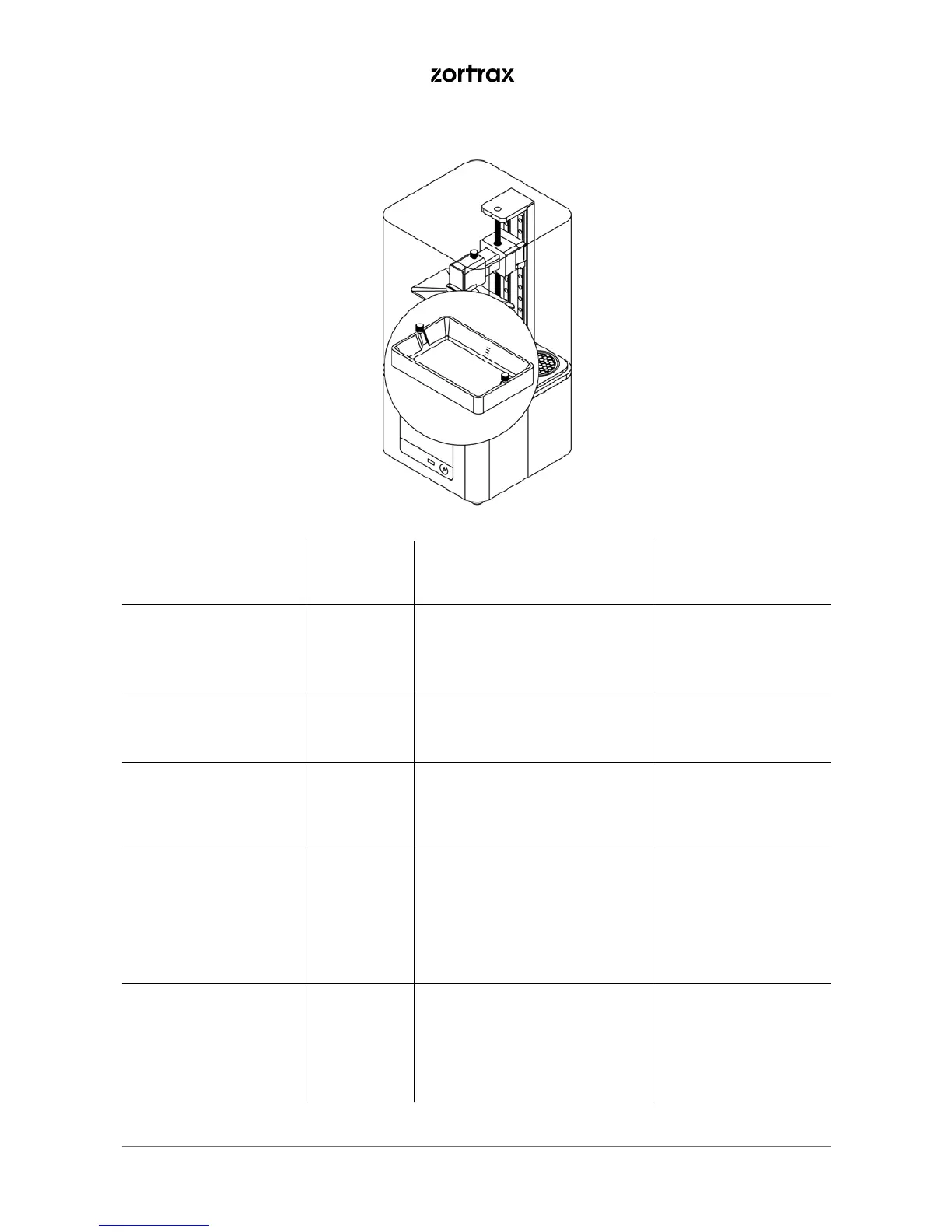

Activity Frequency Solutions to the problems Necessary accessories

Cleaning the underside

of the FEP lm

Every

time the

resin tank is

removed

Soak a paper towel in IPA and

clean the underside of the FEP

lm.

-paper towels,

-IPA,

-safety gloves

Checking if there are

residues of cured resin

in the tank

Before each

printing

process

Use a plastic spatula and slightly

mix the resin to check if there are

any residues in the liquid.

-a plastic spatula,

-safety gloves

Checking if there are

residues of cured resin

on the FEP lm

Before each

printing

process

Empty the resin tank. If there are

any residues of cured resin on

the FEP lm, remove them using

a plastic spatula.

-a plastic spatula,

-safety gloves

Emptying and cleaning

the resin tank

Every time

the resin

type

or color is

changed

Insert the resin lter into the sil-

icone funnel and pour the resin

left in the tank into the bottle.

Follow the instructions in the

manual: https://support.zortrax.

com/resin-tank-cleaning/

-resin lter,

-silicone funnel,

-bottle of resin,

-paper towels,

-a plastic spatula,

-Ultrasonic Cleaner

(optional)

Replacing the FEP lm Once the

FEP lm

becomes

bent, de-

formed, or

perforated

Follow the instructions in the

manual: https://support.zortrax.

com/fep-lm-replacement/

-a new FEP lm,

-a screwdriver,

-paper towels,

-IPA,

-safety gloves

Loading...

Loading...