2600T Series Pressure transmitters | OI/266/FF/ADD-EN Rev. B 33

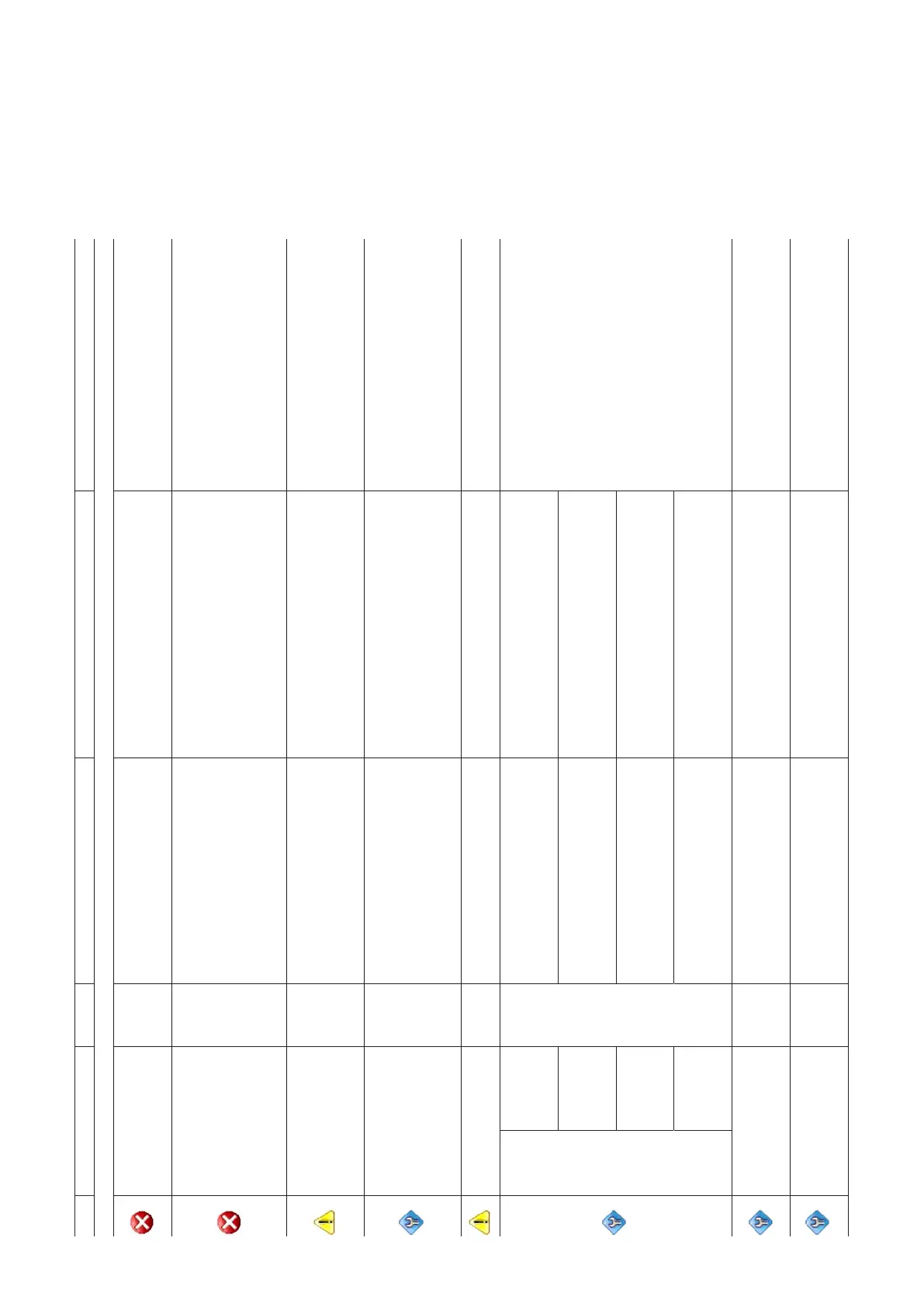

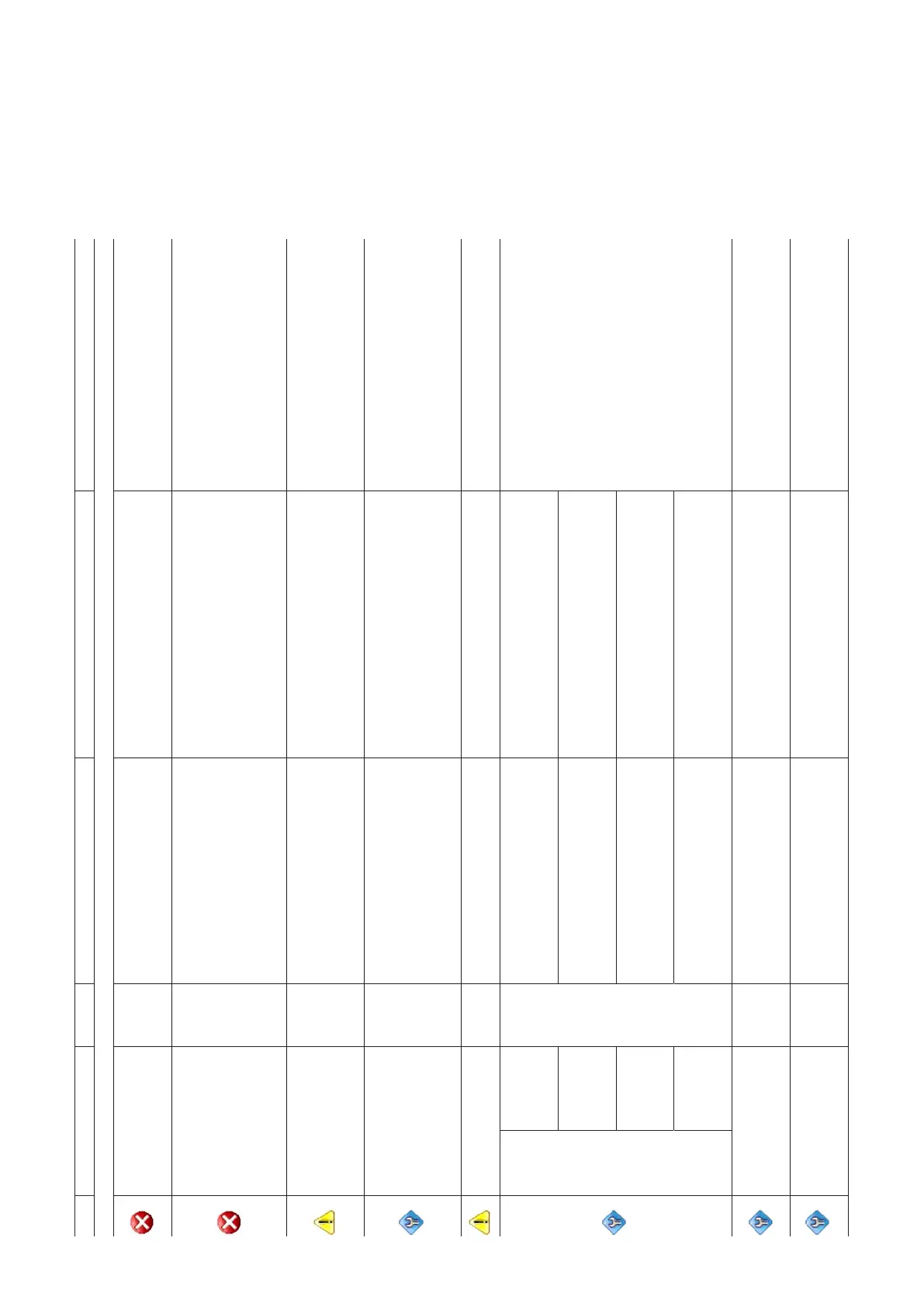

Cat Error HMI code Description Possible Cause Suggested Actions

Process errors

P-dP Out Of Limit F102.004

The measured Process Pressure value is

outside the sensor limits and no longer

representing the true applied process value.

The measurement range has not been correctly

calculated OR an incorrect transducer model has

been selected.

The compatibility of pressure transmitter model

and process conditions has to be checked.

Probably a different transmitter type is required.

Static Pressure Out Of Limit F100.005

The measured Static pressure is above its

operational limit

The static pressure of the process exceeds the limit

of the sensor. Exceeding the Static Pressure can

reduce accuracy, mechanically damage the

diaphragm and may require calibration/replacement.

An incorrect transducer model could have been

selected.

The compatibility of pressure transmitter model

and process conditions has to be checked.

Probably a different transmitter type is required.

Sensor Temperature Out Of

Limit

S054.006

The measured sensor temperature is outside

of its operational limits

The temperature of the process environment affects

the pressure transmitter; Excess temperature can

reduce accuracy, degrade device components and

may require calibration/replacement.

The compatibility of pressure transmitter model

and process conditions has to be checked.

A different installation type could be required e.g.

use of remote seals.

Max. Working Pressure

Exceeded

M052.031

The measured Static Pressure is higher than

the acceptable mechanical limit for the

process connection elements.

The static pressure of the process exceeds the limit

of the max working Pressure supported by the

transmitter. Exceeding the Max Working Pressure

can mechanically damage the process connections

(flanges, pipes….) and/or be dangerous

The compatibility of the process connection type

and material with process conditions has to be

checked. A different installation type could be

required e.g. use of remote seals.

Primary Variable Out of

Range

S050.010 Process value is outside its working range

The measured pressure value is beyond its Low or

High scaling limits

Adjust the working range if possible.

PILD

Output

Both Impulse

Lines Plugged

M018.038

PILD algorithm has detected both impulse

lines plugged.

Both connections between the pressure sensor and

the process are blocked either by plugging or closed

valves.

Check valves and impulse line. Clean impulse

line if necessary and initiate PILD training

High Side

Plugged

PILD algorithm has detected a plugged

impulse line on the HIGH side.

The connection between the pressure sensor and

the process on the HIGH side is blocked either by

plugging or closed valves.

Low Side

Plugged

PILD algorithm has detected a plugged

impulse line on the LOW side.

The connection between the pressure sensor and

the process on the LOW side is blocked either by

plugging or closed valves

Undefined line

plugged

PILD algorithm has detected one plugged

impulse line.

One of the connections between the pressure sensor

and the process is blocked either by plugging or

closed valves.

PILD Changed Operating

Conditions

M016.039

The pressure value currently detected is too

different from what used for the PILD

Training

Process conditions have changed to an extent that

new settings for the PILD algorithm are needed.

A new Training is necessary for this new process

condition

PRTB Out Of Service Transducer Block is Out of Service.

Power has been reapplied resulting in the re-initializa-

tion of the device.

Check transducer block configuration and make

sure that the Target Mode has been set to

Automatic Mode.

Loading...

Loading...