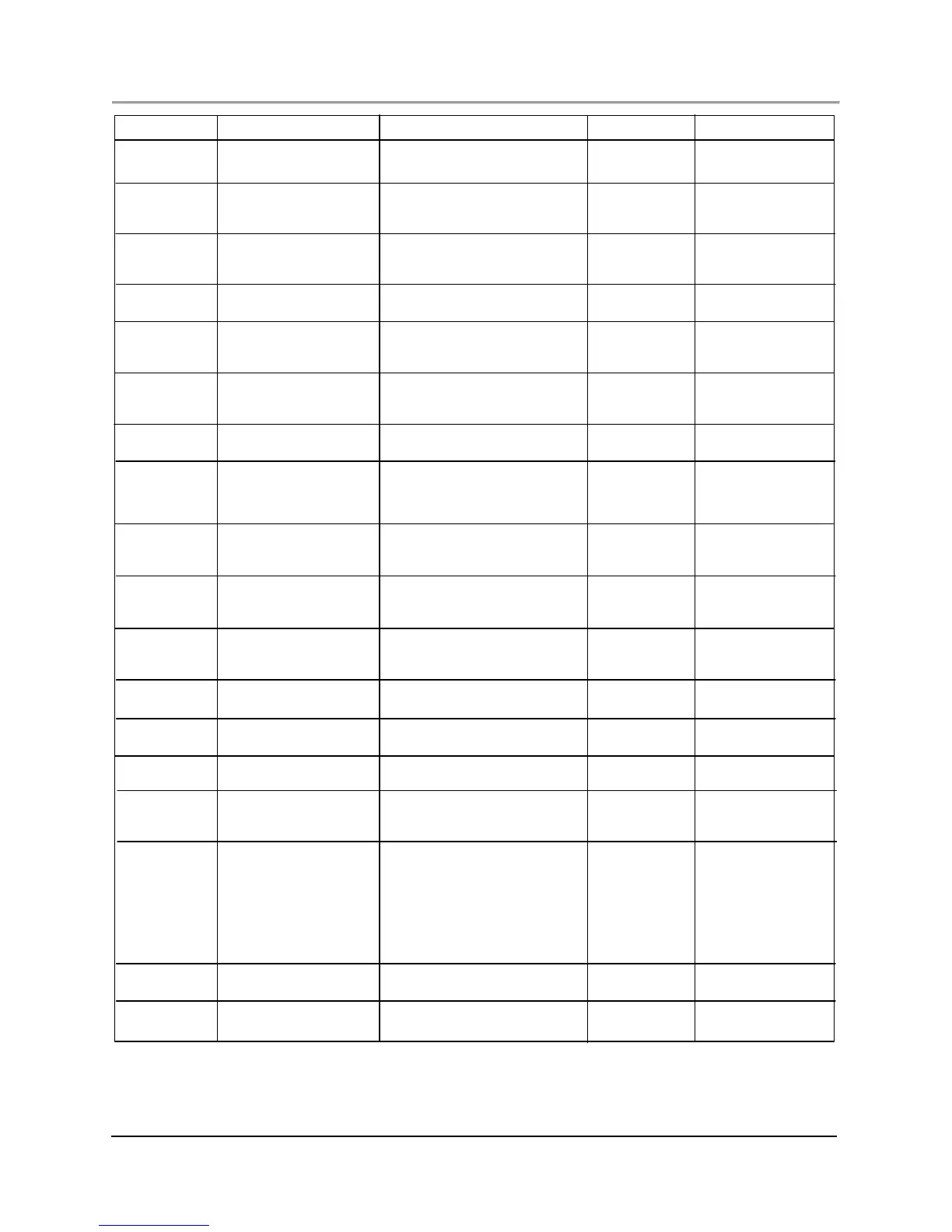

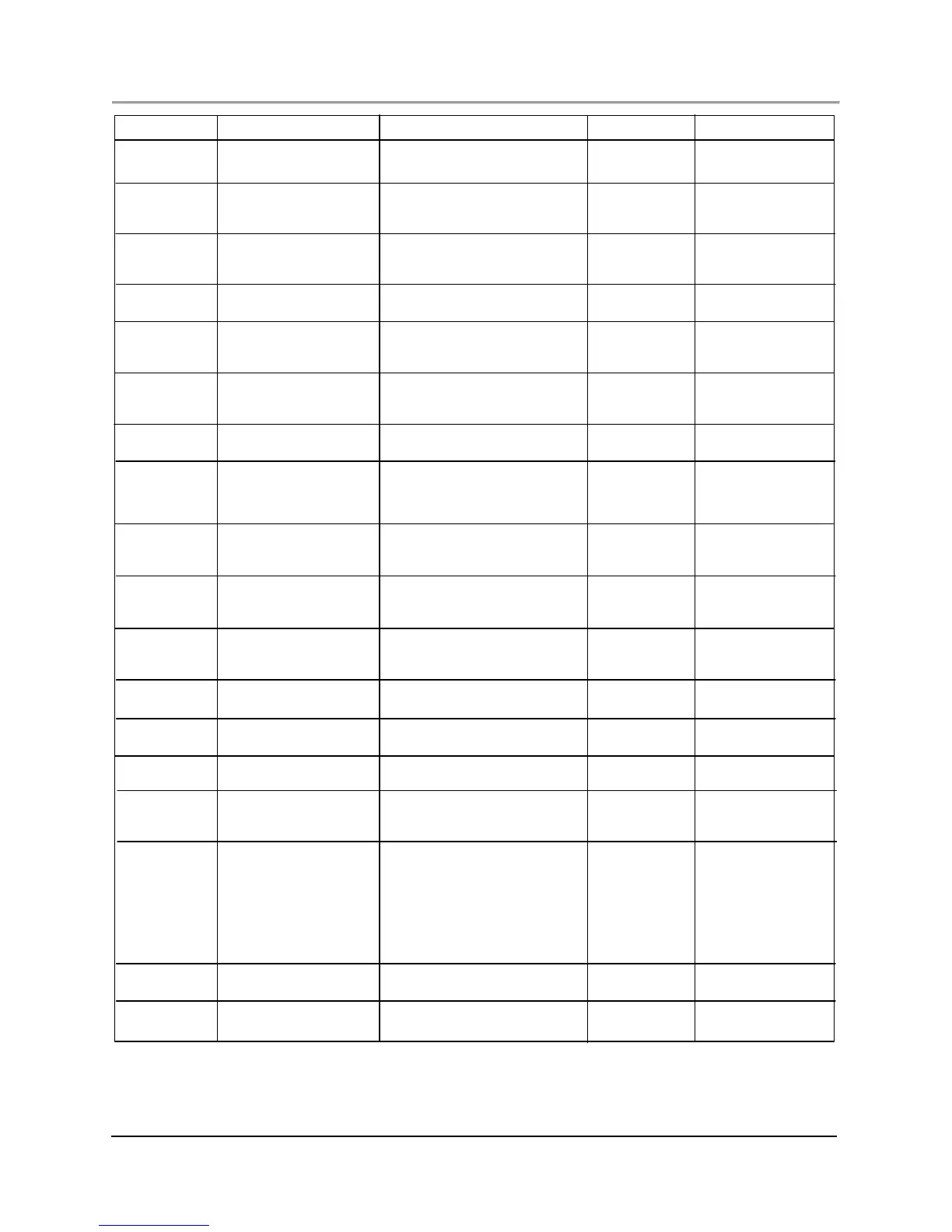

INDICATOR ISSUE RESOLUTION (C HE CK & CORRECT) RESET SOURCE

Low-Low Conce ntrati on i s bel ow Inf orma tion Only. Adjust Limits under When Component

Conce ntrati on Low-Low Setp oi nt the Setup tab as needed. reported.

Low Conce ntrati on i s bel ow Inf orma tion Only. Adjust Limits under When Component

Conce ntrati on Low Setpoint but above the Setup tab as needed. Reported

Low-Low Setp oi nt

High Concentration exceeds the I nf orma tion Only. Adjust Limits under When Component

Conce ntrati on High Setpoint but below the Setup tab as needed reported

High-High Setpoint

High-High Concentration exceeds the I nf orma tion Only. Adjust Limits under When Component

Conce ntrati on High-High Setpoint the Setup tab as needed reported

RF Low Limit Calculated response factor Inf orma ti on Only. Adjust Limits under When Component

out of range (low) (% of the Setup tab as needed. recalibrated

deviation from previous RF)

RF High Limit Calculated response factor I nf orma tion Only. Adjust Limits under When Component

out of range (high) % of the Setup tab as needed recalibrated

deviation from previous RF)

Retention Time Retention time is below Inf orma ti on Only. Adjust Limits under When Component

Low Low Setp oi nt the Setup tab as needed. Reported

Retention Time Retention time exceeds Inf orma tion Only. Adjust Limits under When Component

High High Setjpoint the Setup tab as needed. Possible reported

leak. Possible defective EPC pressure

sensor. Possi ble plugged inlet filter.

Validation Measurement out of range Inf orma tion Only. Adjust Limits under We n Component

(% of deviation from known the Setup tab as needed. Flows revali da ted

standard) incorrectly set. Defective EPC se nsor.

Missing No peak found matching a Inf orma ti on. Edit analysis as needed. When Analysis

Component component defined in the reported

analysis

Unkno wn Peak detected in the Che ck f lo ws. Verify correct operation When Analysis

Component analysis and not defined in operation of all ana lytical valves. Reported

the me tho d Verify sample flow to oven.

Sampl e Fl ow L os t Future functionality: Restore Sample flow. Replace s ample AOC Analysis

Sample f low is lost flow switch as necessary

Digin Check TCF Progr ammabl e Input See Digital inut TCF in Operating AOC Analysi s

checks Inst ructi o ns.

Psrs C he ck T CF Pressure Check failed See pressure check TCF in AOC Analysi s

Operati ng Instr ucti ons.

Invalid Analysis Analysis failed validation 1. From Analysis tab edit Analysis to AOC Analysi s

meet requireemnts.

2. User control led.

Analysis Aborted 1. Analysis does not 1. Check Pressure, Temperature AOC Analysis

complete analysis due to and/or Digit al In puts. Correct problem

temperature, pre ssure accordingly.

and/or di gital input 2. User control led.

programmed command. 3. Che ck o ven rel ate d indi cators for

2. User intervention using more information.

Stop Now command.

3. Related oven issues.

Offline Schedule Offline: Oven i s Inf orma ti on Only. Resets when oven AOC Schedule

powered down power is res tored.

Idl e Schedule Stopped or Inf orma ti on Only. AOC Schedule

pause d

Loading...

Loading...