14 RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | SEI/RHD250/4000-EN REV. A

… 4 Maintenance

… Motor

Motor removal

Danger to life due to unexpected movement of the actuator!

Note that the actuator position may be changed accidentally

by the external load on the drive when the brake is released, or

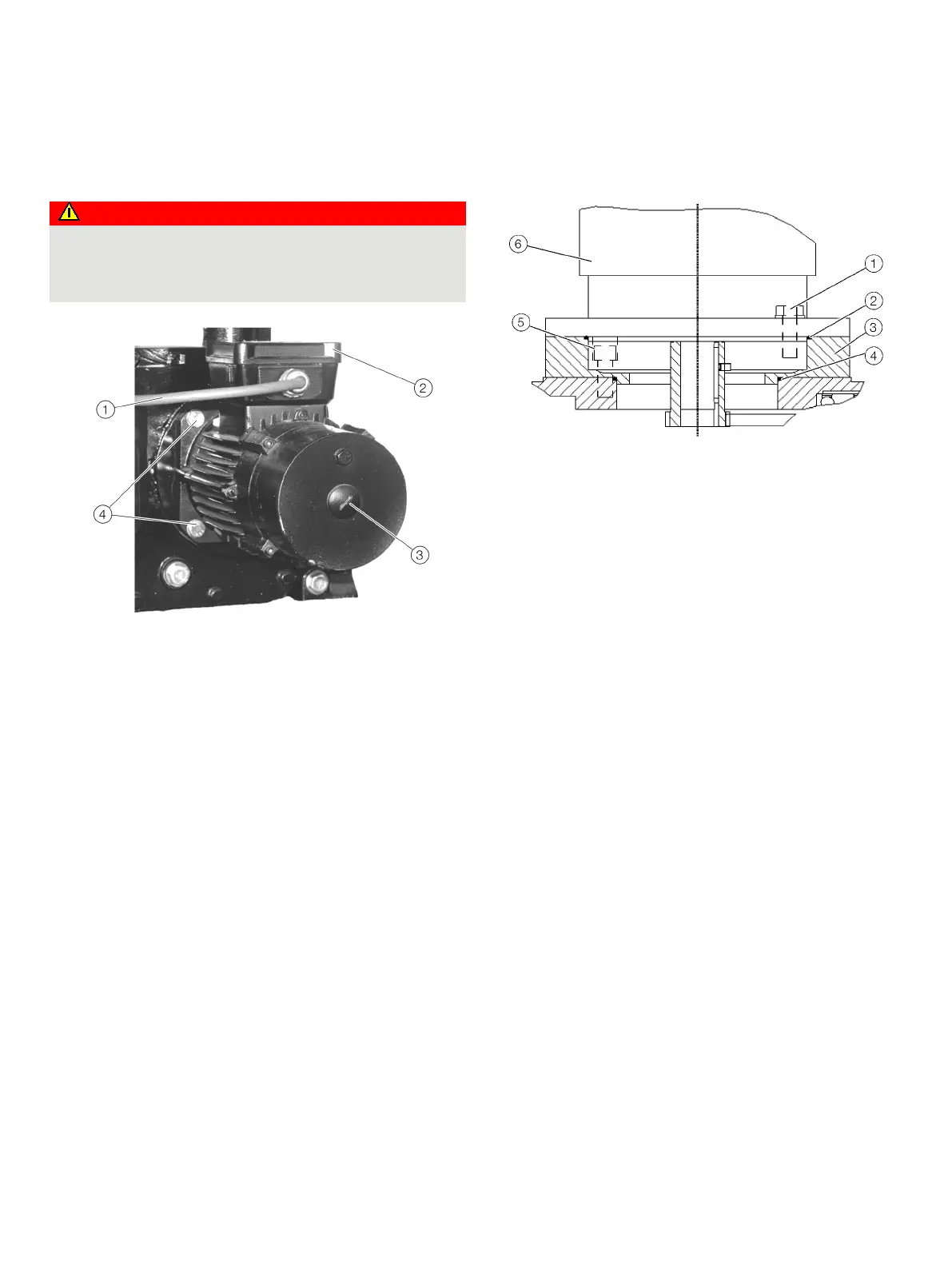

Motor connection cable

Motor terminal box

Motor

Motor fastening screws

Figure 12: Rear motor view (exemplified)

1. Disconnect the motor / actuator from any electrical supply.

2. Disconnect motor connection cable in motor terminal box.

3. Drain the oil (see Mounting position on page 6 for details).

4. Undo the 4 motor fastening screws.

5. Pull the motor carefully out.

6. Once the motor overhaul is finished, replace the motor

sealing ring in any case.

7. Install the motor in reverse order.

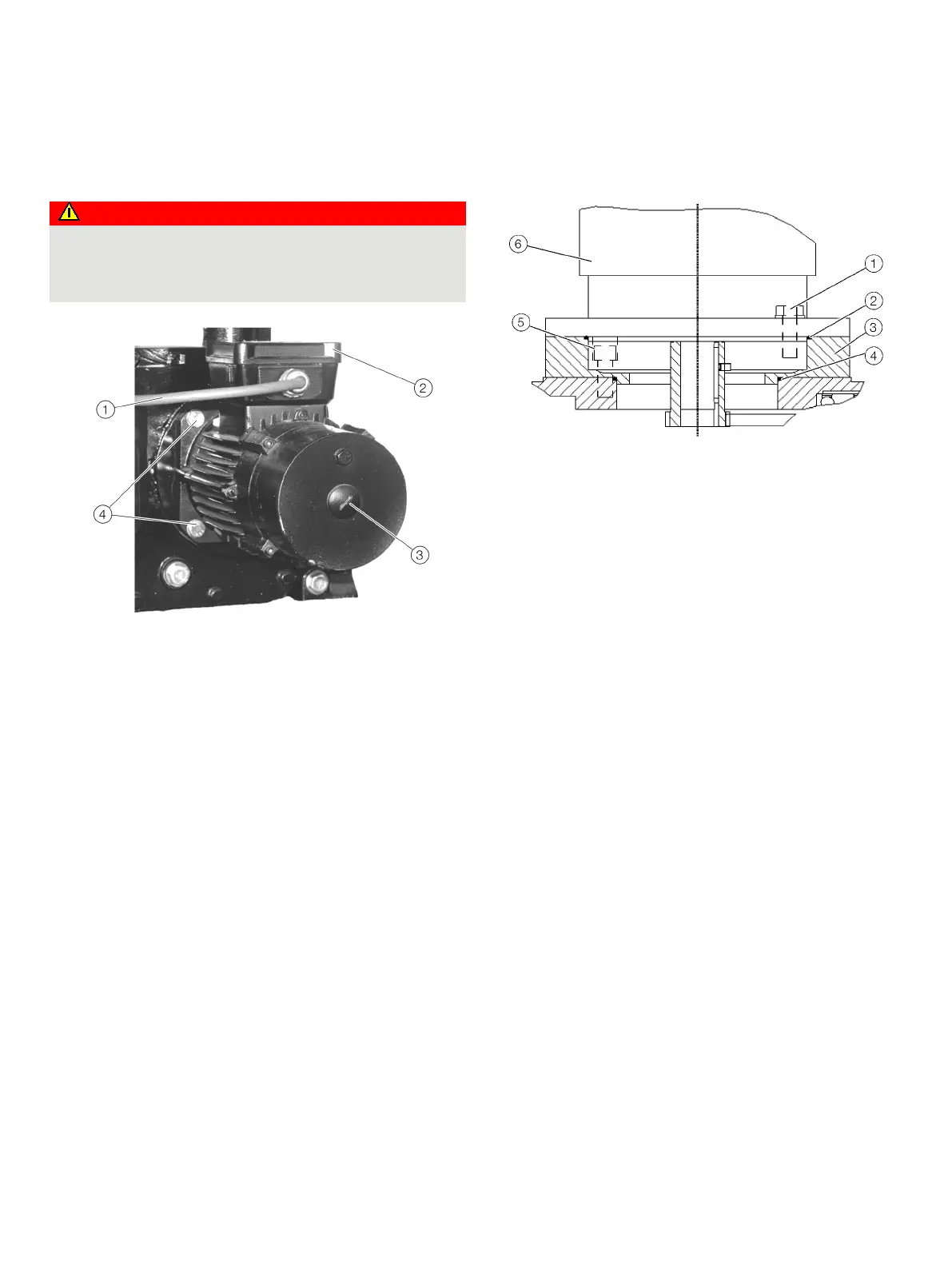

Motor flange O-ring

Motor screw

O-ring

Flange

O-ring

Screw

Motor

Figure 13: Exemplary depiction of motor connection; additional flange

not used for

all motors

In order to change the flange O-ring proceed as follows:

1. Disconnect the electrical power supply prior to any

maintenance

2. Make sure that the oil level is below the O-ring

4

3. Drain the oil if necessary Mounting position on page 6.

4. Disconnect the cables in the motor terminal box

5. Turn the motor screws

1 out and put the motor aside;

remove O-ring

2

6. Turn the screws

5 of the add. flange out and put the

flange

3 aside; remove O-ring 4

7. Replace O-ring

4

8. Mount the additional flange

3 at the actuator housing and

fasten it with the flange screws

5

9. Put the new O-ring

2 into the flange groove and fasten the

motor with the screws

1; consider tightening torque shown

Motor assignment and tightening torque on page 13.

Loading...

Loading...