RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | SEI/RHD250/4000-EN REV. A 19

Brake adjustment

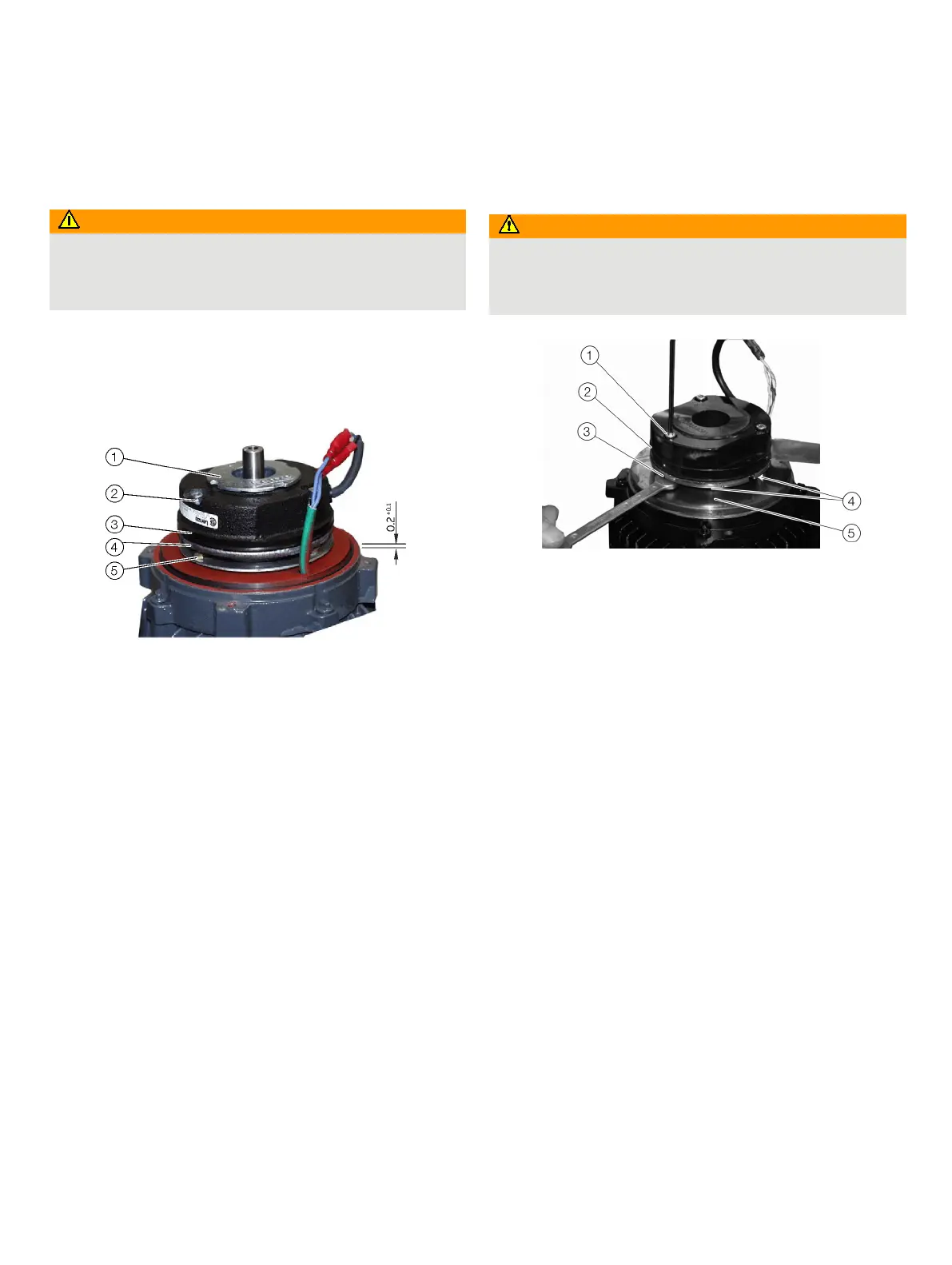

Brake of motor series 1

Risk of injury

Note that the actuator position may be changed accidentally

by the external load on the drive when the brake is released or

Note

Do not turn the slotted nut

1. It preloads the brake spring. Any

disadjustment may reduce the brake

force and thus disable the brake to hold the actuator in position!

Slotted nut

Socket head screws

Coil body

Brake disk

Counter nuts

Figure 32: Brake of motor series 1

In automatic mode the brake is permanently released. Therefore,

it is not exposed to wear and does usually not require any re-

adjustment. The gap between coil body and brake disk should be

approx. 0.2

+0.1

mm (0.008 to 0.012 inch). To check the gap

switch-off the voltage supply and put a thickness gauge

between the coil body

3 and the brake disk 4. If the brake

requires an adjustment (e. g. after replacement) proceed as

follows:

1. Disconnect the voltage supply.

2. Remove the brake cover.

3. Loosen the socket head screws

2.

4. Put a thickness gauge (0.2 mm) between the coil body

3

and the thrust plate

4.

5. Turn the counter nuts

5 until the thickness gauge is

tautly between coil body

3 and thrust plate 4.

6. Tighten the socket head screws

2 evenly.

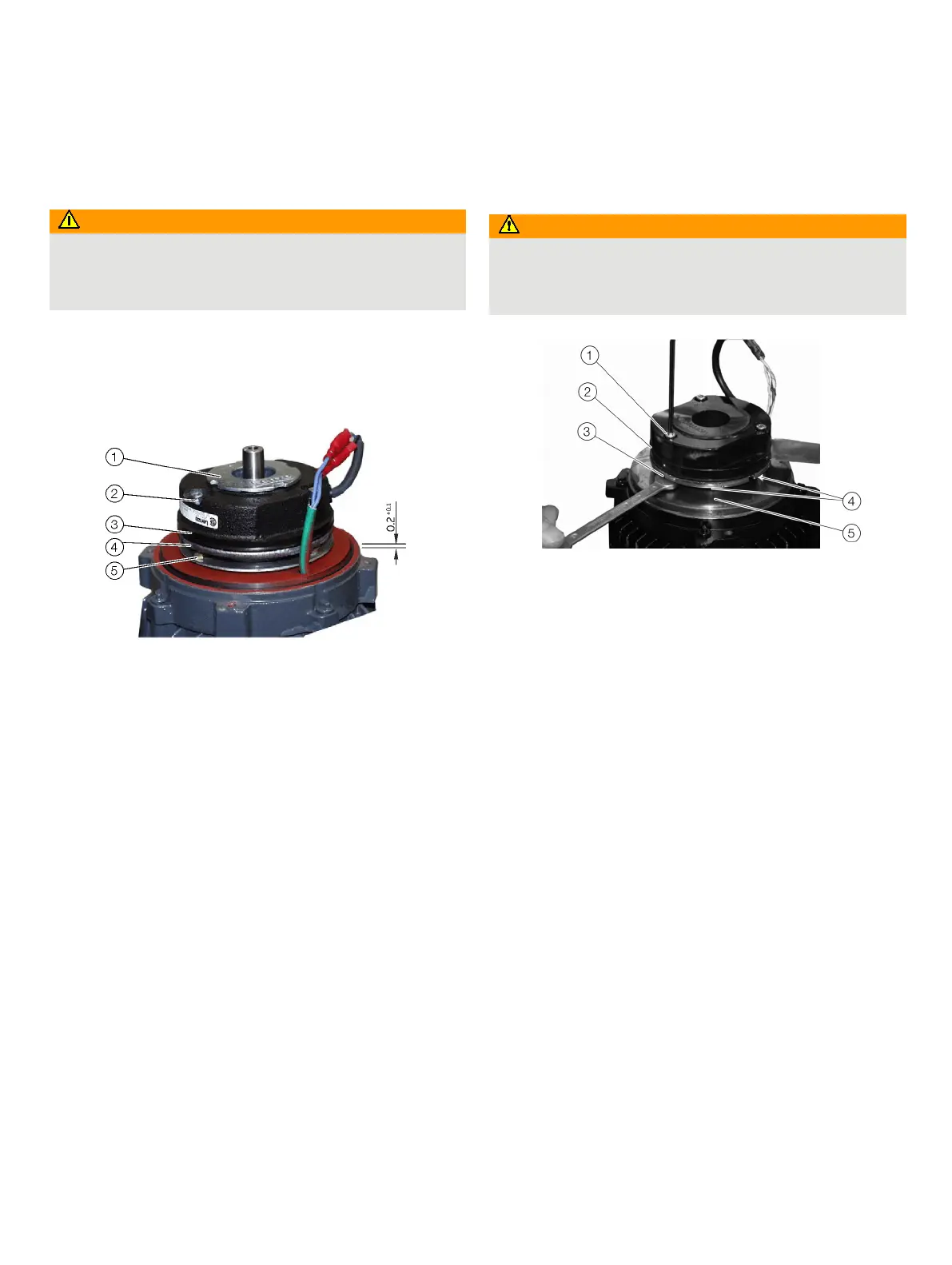

Brake of motor series 2

Risk of injury

Note that the actuator position may be changed accidentally

by the external load on the drive when the brake is released or

Socket head screws

Coil body

Thrust plate

Brake disk

Base plate

Figure 33: Brake of motor series 2

In automatic mode the brake is permanently released. Therefore,

it is not exposed to wear and does usually not require any re-

adjustment. The gap between coil body and brake disk should be

approx. 0.2

+0.1

mm (0.008 to 0.012 inch). To check the gap

switch-off the voltage supply and put a thickness gauge

between the coil body

2 and the brake disk 4. If the brake

requires an adjustment (e. g. after replacement) proceed as

follows:

1. Disconnect the voltage supply.

2. Remove the brake cover.

3. Turn the socket head screws

1 completely out.

4. Take the brake body

2 off.

5. Turn the hexagon nuts

4 cw until they are in touch with

the brake body

2.

6. Put the brake body

2 onto the shaft and tighten the

screws

1; hand screwed.

7. Turn the hexagon nuts

4 ccw until they are in touch with

the base plate

5.

8. Evenly turn the socket head screws

1 approx 1/3 turn

ccw (approx 120°); this also lifts the hexagon nuts

4.

9. Turn the hexagon screws

4 until they are in touch with

the brake body

5.

10. Check the gap between brake body

2 and thrust

plate

3 using a thickness gauge 0.2

+0.1

mm

(0.008 to 0.012 inch).

Loading...

Loading...