6 RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | SEI/RHD250/4000-EN REV. A

3 Lubrication

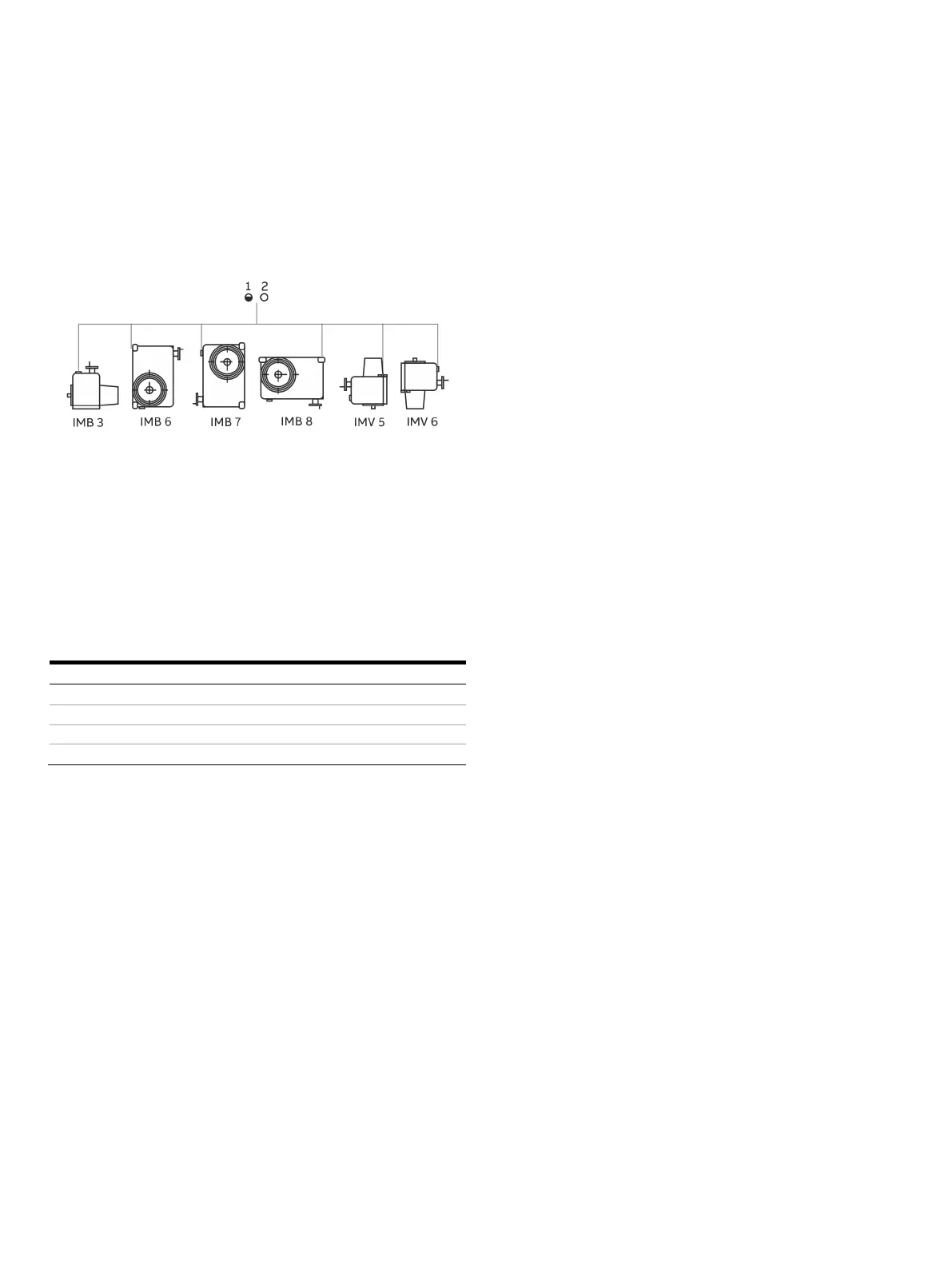

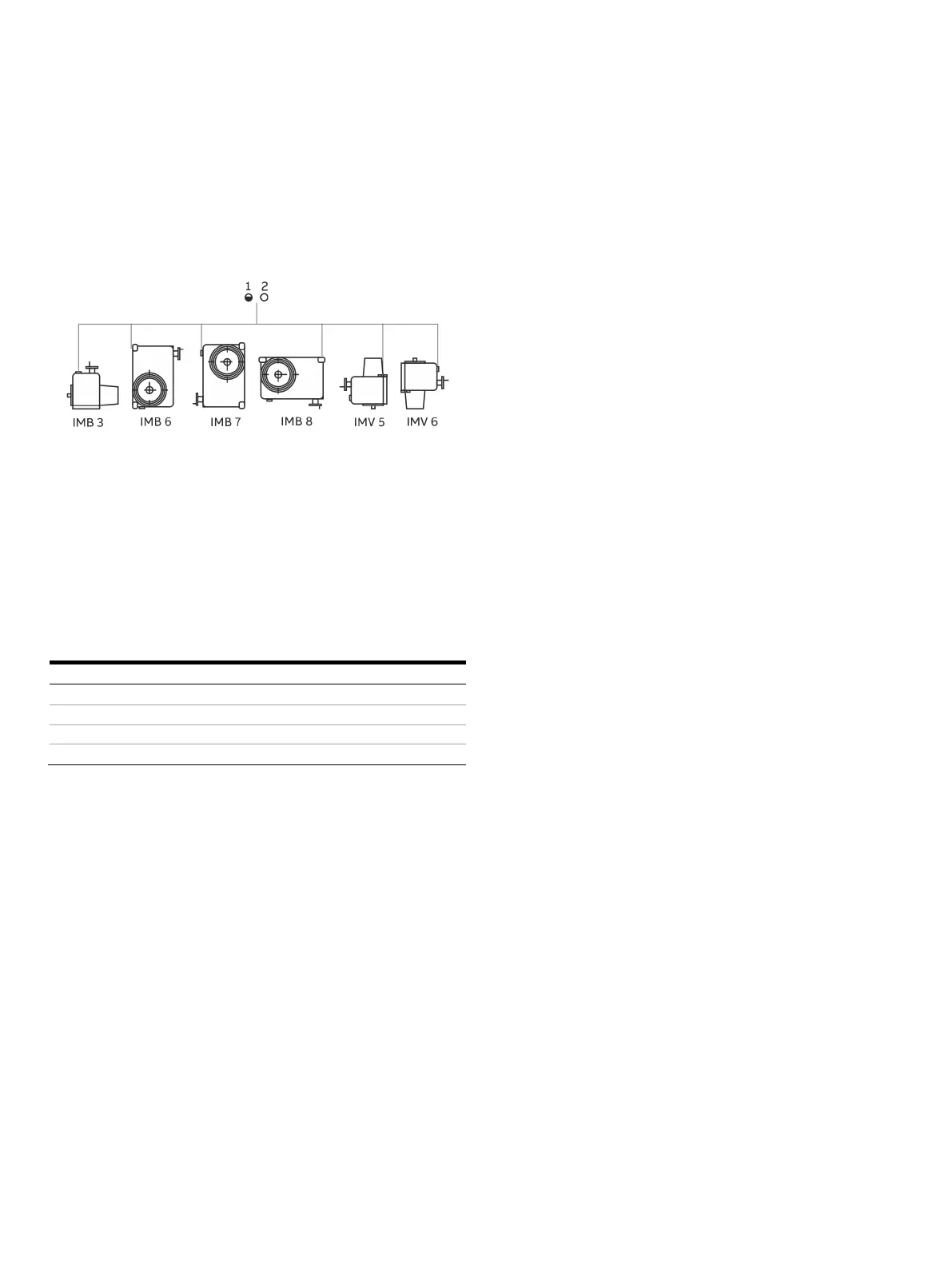

Mounting position

The spur gearing of the actuator RHD250 / RHD500 / RHD800 /

RHD1250 / RHD2500 / RHD4000 (Contrac) are lubricated with

oil. They contain the max. oil quantity when leaving the

manufacturer. Once the actuator is installed replace the

uppermost check plug by the separately supplied venting plug.

Control screw

Vent valve

Figure 2: Permissible mounting positions

The mounting positions presented are permissible. To facilitate

mounting and maintenance, however, it is recommended that

you use position IMB 3 For each mounting position, you should

check the specified oil level before commissioning, see Filling

volumes on page 7.

To achieve this, allow for the following minimum distances:

40 mm (1.

Oil change

Note

Oils for different temperature ranges may not mixed.

During an oil change, thoroughly remove any oil that may have

escaped to avoid accidents.

Dispose of old oil according to local regulations. Make sure that

the oil does not enter the water cycle. Make sure that any oil

leaking from the device cannot come into contact with hot

components.

Proceed as follows to drain or change the oil:

1. Provide a collecting vessel capable of holding the expected

oil quantity in accordance with Filling volumes on page 7 .

2. Open and release the vent valve, see Mounting position on

page 6.

3. Unscrew the lowermost drain plug to drain the oil.

4. Collect the oil in the collection vessel.

5. Make sure all of the oil has been removed from the actuator

housing.

6. Screw the drain plug back in.

7. Refill with the proper volume of oil in accordance with Filling

volumes on page 7 and securely tighten the vent valve.

Loading...

Loading...