RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | SEI/RHD250/4000-EN REV. A 27

6 Exchange of position sensor

Dismounting

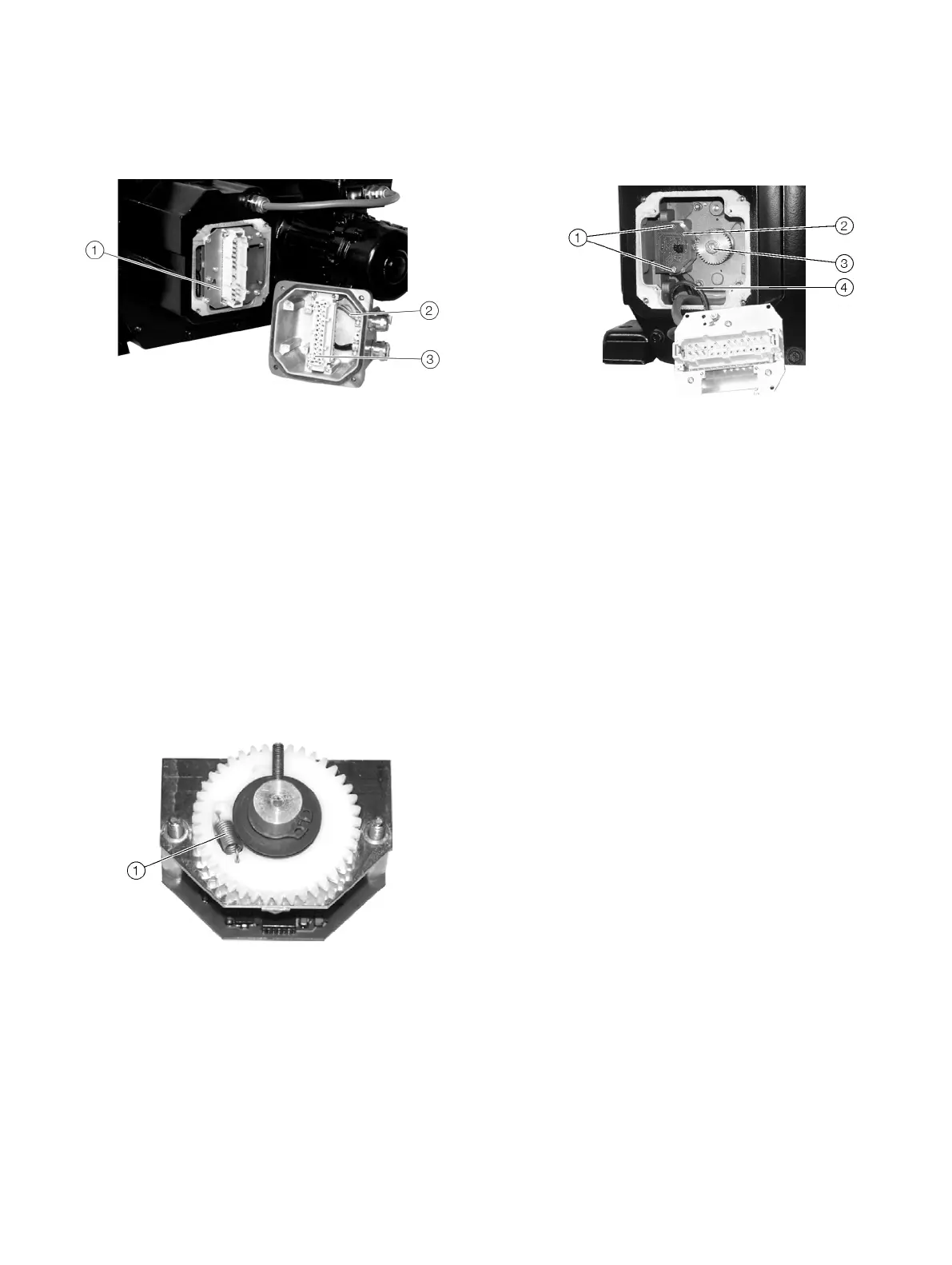

Male connector

Plug housing

Female connector

Figure 47: Example shows RHD500 (without heater)

1. Drive actuator into 50% position (referred to rated actuator

operating range).

2. Delete the current position settings by pressing the 2 drive

buttons on the LCP for at least 5 sec.

3. Switch-off the voltage supply.

4. Disconnect electrically.

5. Remove male connector.

6. Loosen both fastening screws

1 of position sensor (Figure

51) and take the sensor out.

7. Detach the plug from the sensor pcb.

Mounting

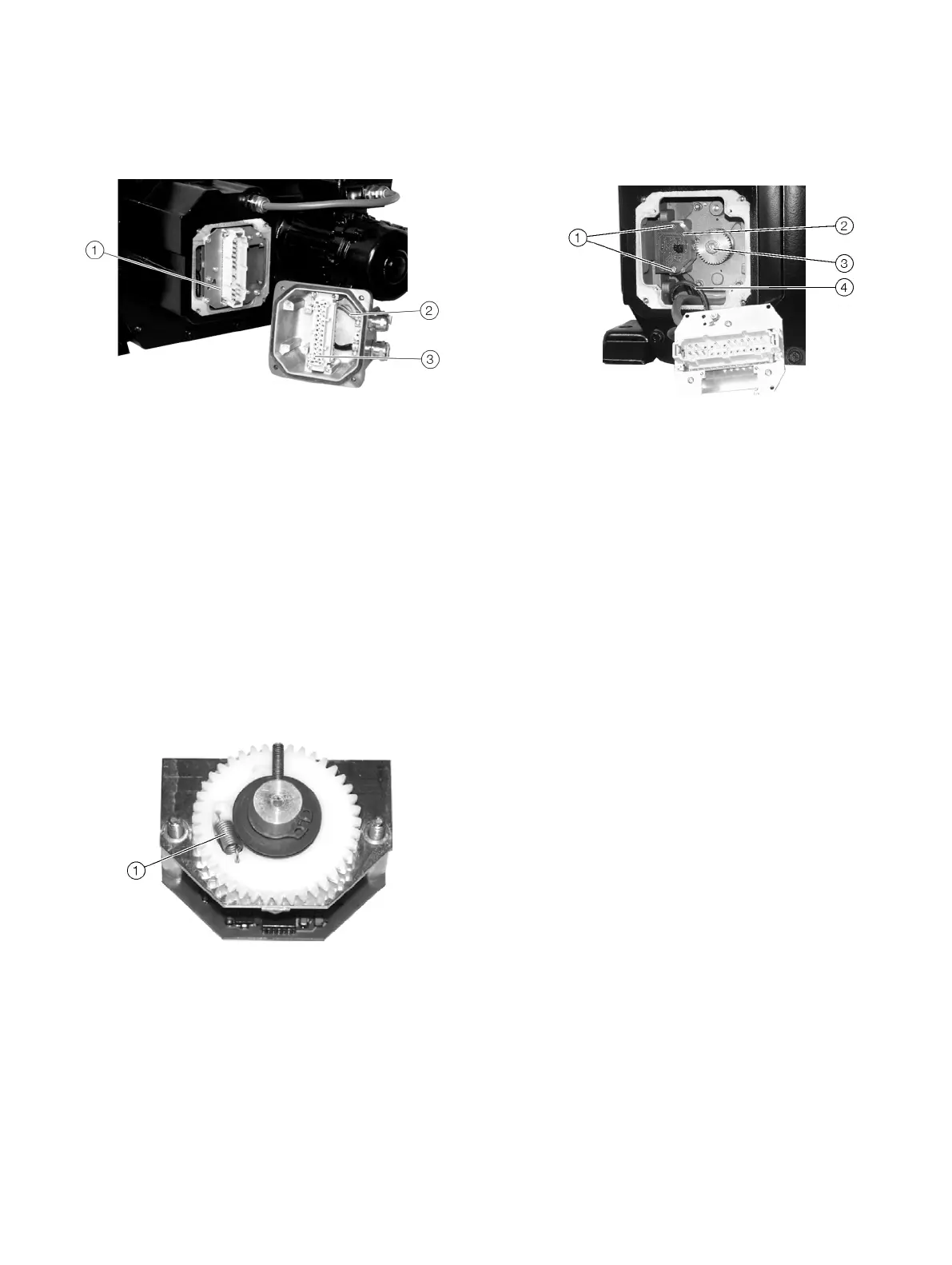

Tension spring

Figure 48: Position sensor

The toothed gear pair of the position sensor is held in place by a

tension spring

1, to ensure backlashfree motion when the

direction of rotation is reversed.

1. Set the stop pin to the center position, as shown in Figure

50.

Fastening screws

Position sensor

Shaft gear

Sensor cable

Figure 49: Mounting position (Example shows RHD500)

2. Align the sensor and its gears with the actuator; set the first

toothed gear in 09:00 o’clock position (Figure 51) onto the

drive shaft gear

3.

3. Slightly move the sensor back and forth to pre-tension the

toothed gears with the difference ‘z’ until the second

toothed gear snaps in.

4. Fasten the screws

1 tightly.

5. Fasten sensor cable plug on sensor pcb

6. For the remaining assembly steps follow the disassembly

procedure in reverse order

7. After mounting is completed readjust the actuator range as

described in the setup section of this manual

Loading...

Loading...