Access Sensor Technologies UPAS User Guide 19

Optional – Greasing the Cyclone Input

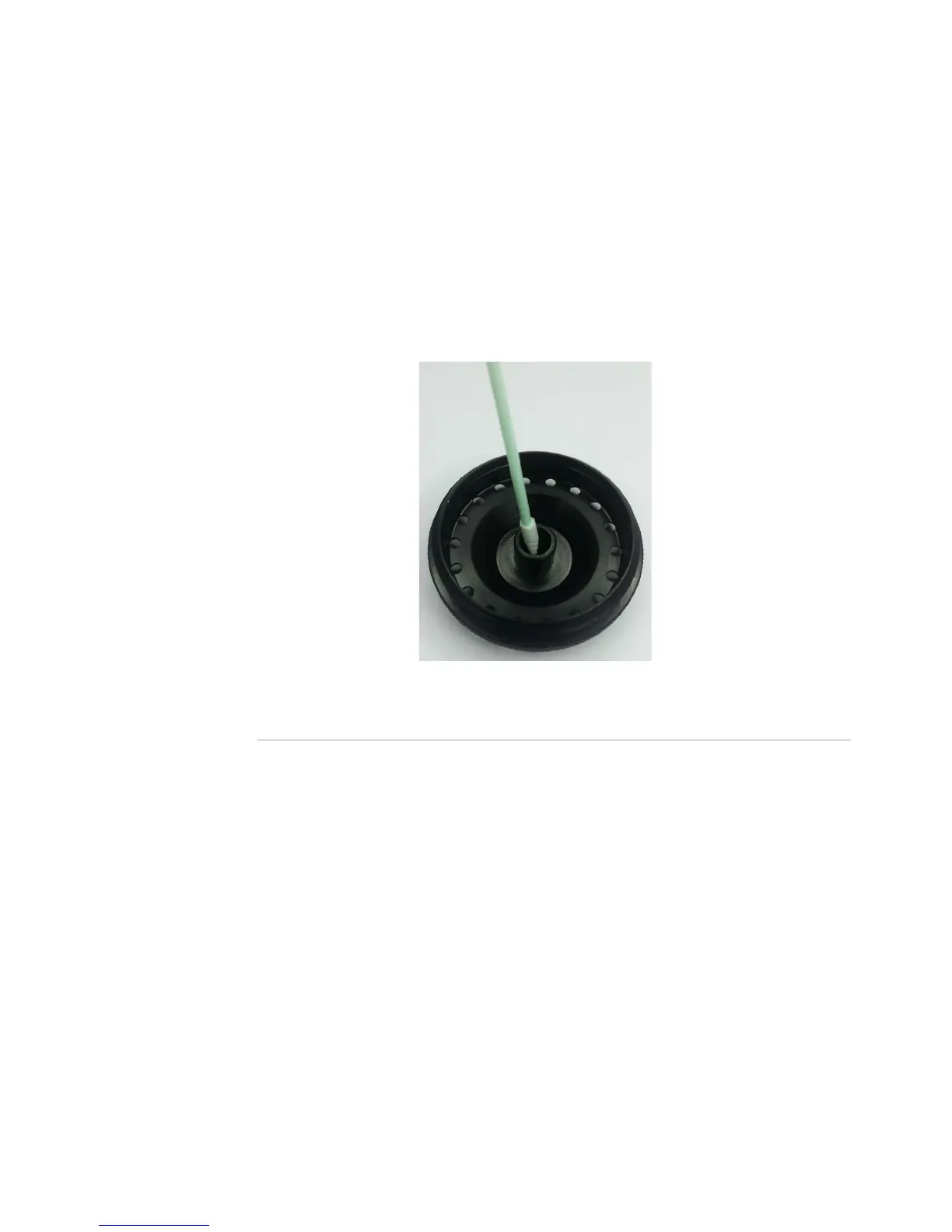

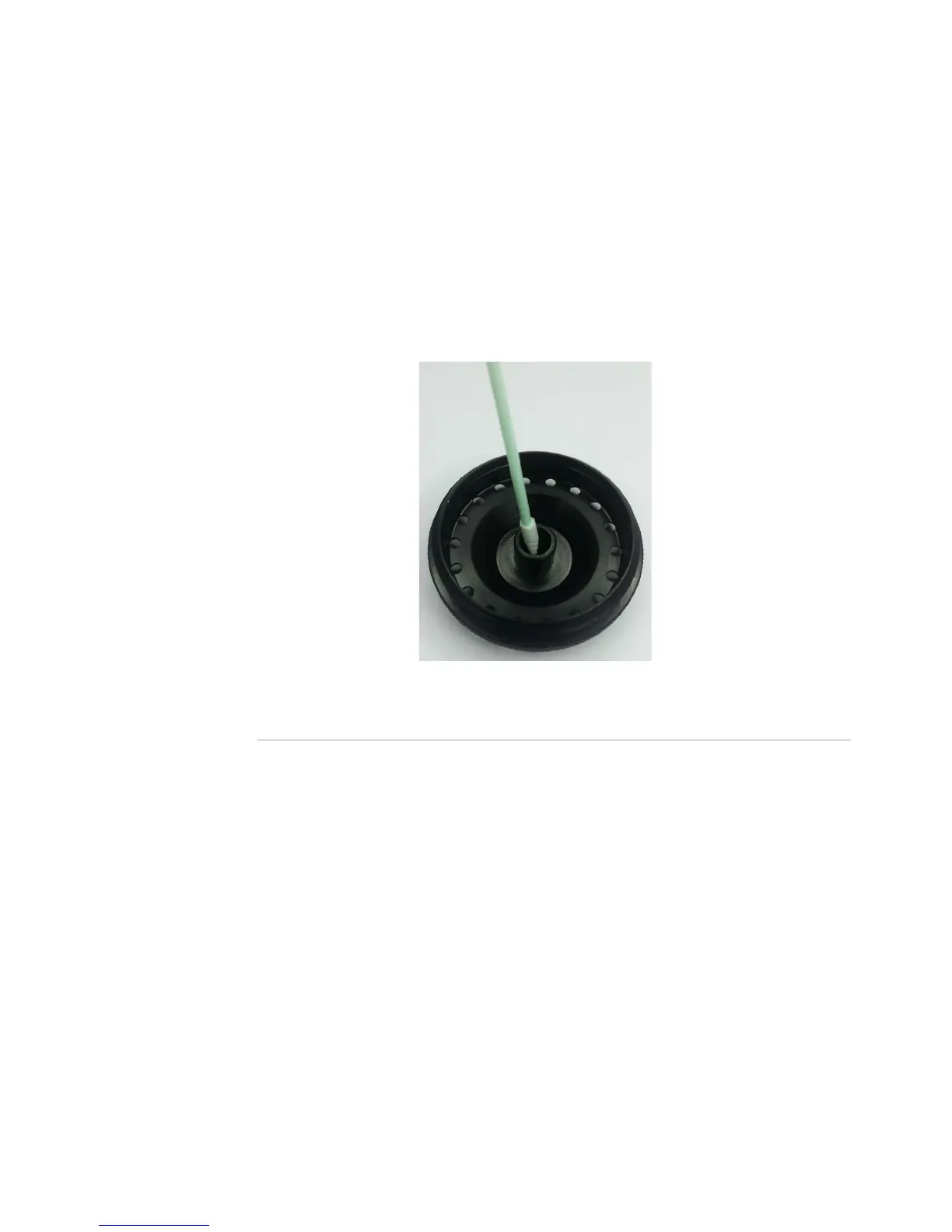

Carefully inspect and clean the inside of the cone in the Cyclone Inlet Cap with a

small soft-bristled brush or pointed foam applicator. Do not use round-tip cotton

swabs or any other brush/swab that is not capable of reaching the bottom of the

pointed conical chamber cavity of the cyclone cap. Any brush/swab that is too

blunt or round may force particulates into the bottom point. Any particulates

remaining at the bottom point of the cyclone cap chamber can become dislodged

during subsequent sampling runs and contaminate the filter.

If grease was previously used, use isopropyl alcohol or ethanol to remove any

remaining grease residue. Do not use any other chemical solvents.

After cleaning, apply a very thin layer of Dow Corning 976 or 976V High Vacuum

grease to the inside of the small cone in the Cyclone Inlet Cap. (Note: If the UPAS

Sampler is used in environments of very high PM concentration, the cyclone can

become overloaded to the point that severe vibration can dislodge rejected PM

trapped on cyclone wall surfaces.) The grease can re-trap any rejected PM which

becomes dislodged in these events and help prevent them from falling into the

filter cartridge. This grease must be removed and replaced between sampling

runs.

Loading...

Loading...