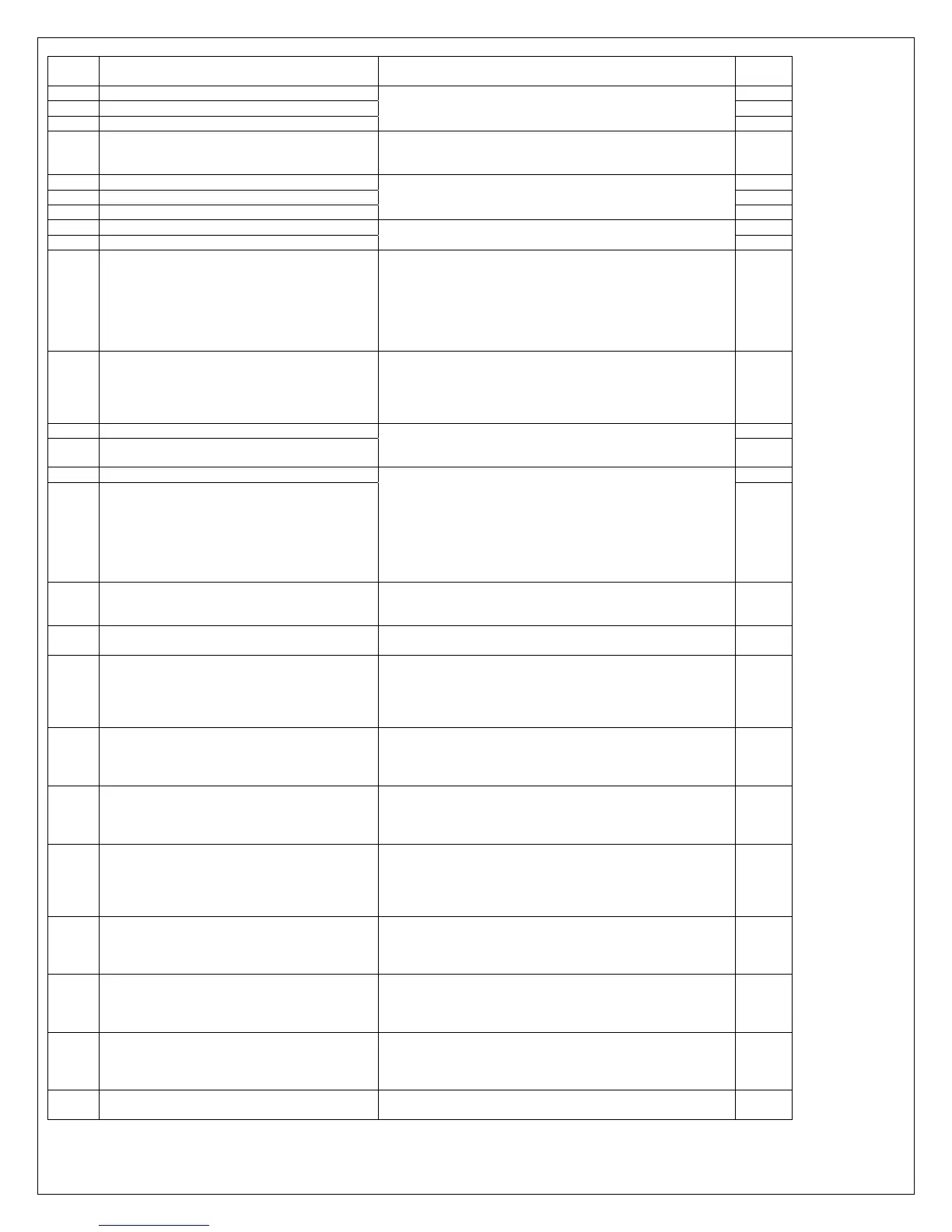

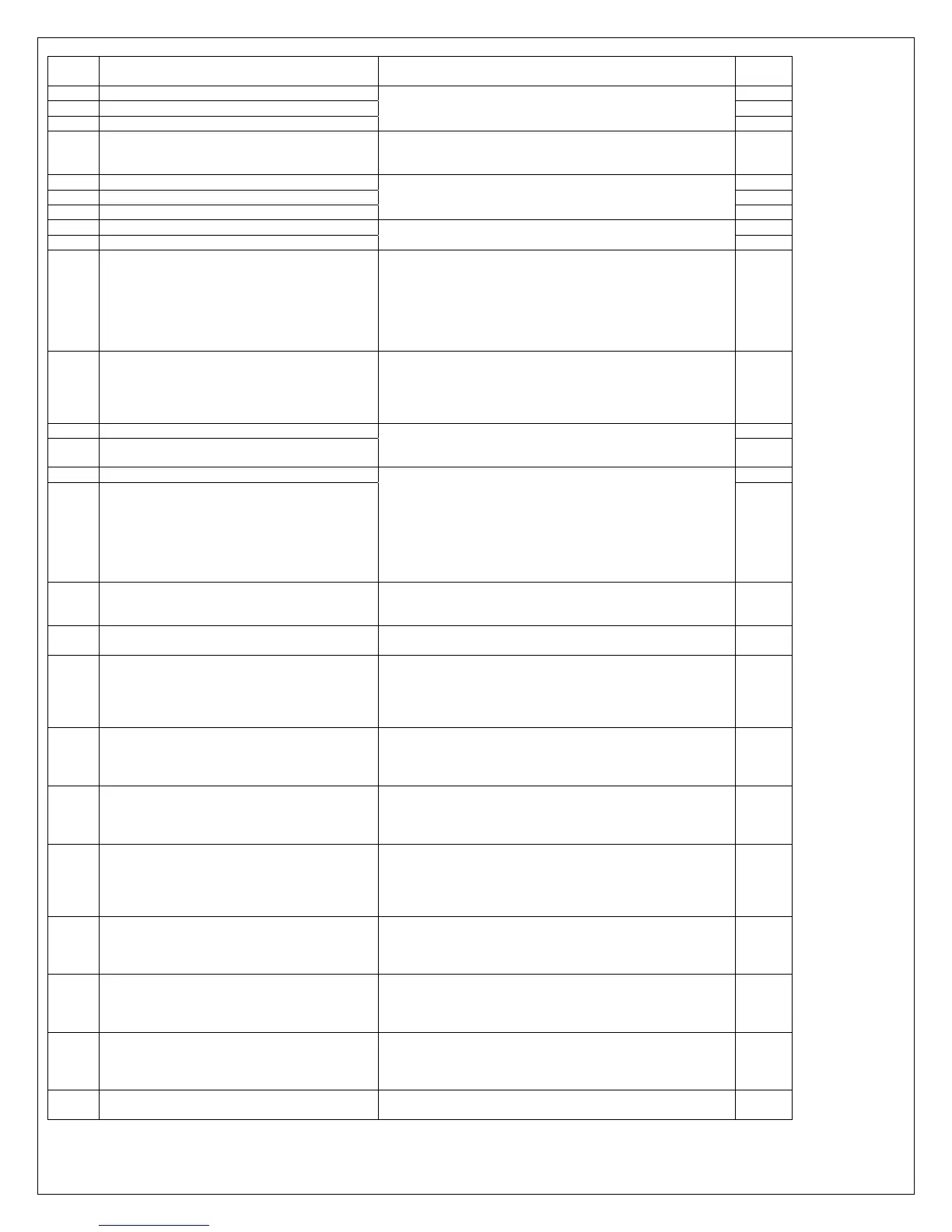

103

Rev 2.1

2. Check the Module power supply and make sure that

frequency, voltage and VA meet the specifications.

50 Modulation fault Internal sub-system fault.

1. Review alert messages for possible trends.

2. Correct possible problems.

H

51 Pump fault H

52 Motor tachometer fault H

53 AC inputs phase reversed 1. Check the Module and display connections.

2. Check the Module power supply and make sure that both

frequency and voltage meet the specifications.

L

58 Internal fault: HFS shorted to IAS Internal Fault.

1. Reset Module.

2. If fault repeats, consult factory

L

59 Internal Fault: Mux pin shorted L

60 Internal Fault: HFS shorted to LFS L

61 Anti short cycle Will not be a lockout fault. Hold Only. H

62 Fan speed not Proved H

63 LCI OFF

1.Check field installed Recycle Interlock switch and wiring to

assure proper function.

2. Check all Limit switches (Burner Cutoff, Gas Pressure,

Drain and Water Flow switches) switches to assure proper

function.

3. Reset and sequence the module; monitor the LCI status.

4. If code persists, consult factory

H

64 PII OFF 1. Check field installed Pre-Ignition Interlock switch and wiring

to assure proper functions.

2. Check PII configuration setting.

3. Reset and sequence the module; monitor the PII status.

4. If code persists, consult factory.

H or L

65 Interrupted Airflow Switch OFF Internal Fault

1. Reset Module.

2. If fault repeats, consult factory

H or L

66 Interrupted Airflow Switch ON H or L

67 ILK OFF 1. Check field installed Lockout Interlock switch and wiring to

assure proper function.

2. Check Airflow switch to assure proper function. Adjust the

air

3. Verify voltage through the interlock string to the interlock

input with a voltmeter.

4. If steps 1-3 are correct and the fault persists, consult

factory.

H or L

68 ILK ON H or L

69 Pilot test hold 1. Verify Run/Test is changed to Run.

2. Reset Module.

3. If fault repeats, consult factory.

H

70 Wait for leakage test Completion 1. Internal Fault. Reset Module.

2. If fault repeats, consult factory.

H

78 Demand Lost in Run 1. Check for adequate gas supply at the gas inlet.

2. Remove the UV flame detector and clean the lens using a

soft cloth.

3. If previous steps are correct and fault persists, consult

factory.

L

79 Outlet high limit 1. Check wiring and correct any possible errors.

2. Replace the Outlet high limit.

3. If previous steps are correct and fault persists, consult

factory.

H or L

80 DHW high limit 1. Check wiring and correct any possible errors.

2. Replace the DHW high limit.

3. If previous steps are correct and fault persists, consult

factory.

H or L

81 Delta T limit 1. Check Inlet and Outlet sensors and pump circuits for

proper operation.

2. Recheck the Delta T Limit to confirm proper setting.

3. If previous steps are correct and fault persists, consult

factory.

H or L

82 Stack limit 1. Check wiring and correct any possible errors.

2. Replace the Stack high limit.

3. If previous steps are correct and fault persists, consult

factory.

H or L

91 Inlet sensor fault 1. Check wiring and correct any possible errors.

2. Replace the Inlet sensor.

3. If previous steps are correct and fault persists, consult

factory.

H

92 Outlet sensor fault 1. Check wiring and correct any possible errors.

2. Replace the Outlet sensor.

3. If previous steps are correct and fault persists, consult

factory.

H

93 DHW sensor fault 1. Check wiring and correct any possible errors.

2. Replace the DHW sensor.

H

Loading...

Loading...