62

Rev 2.1

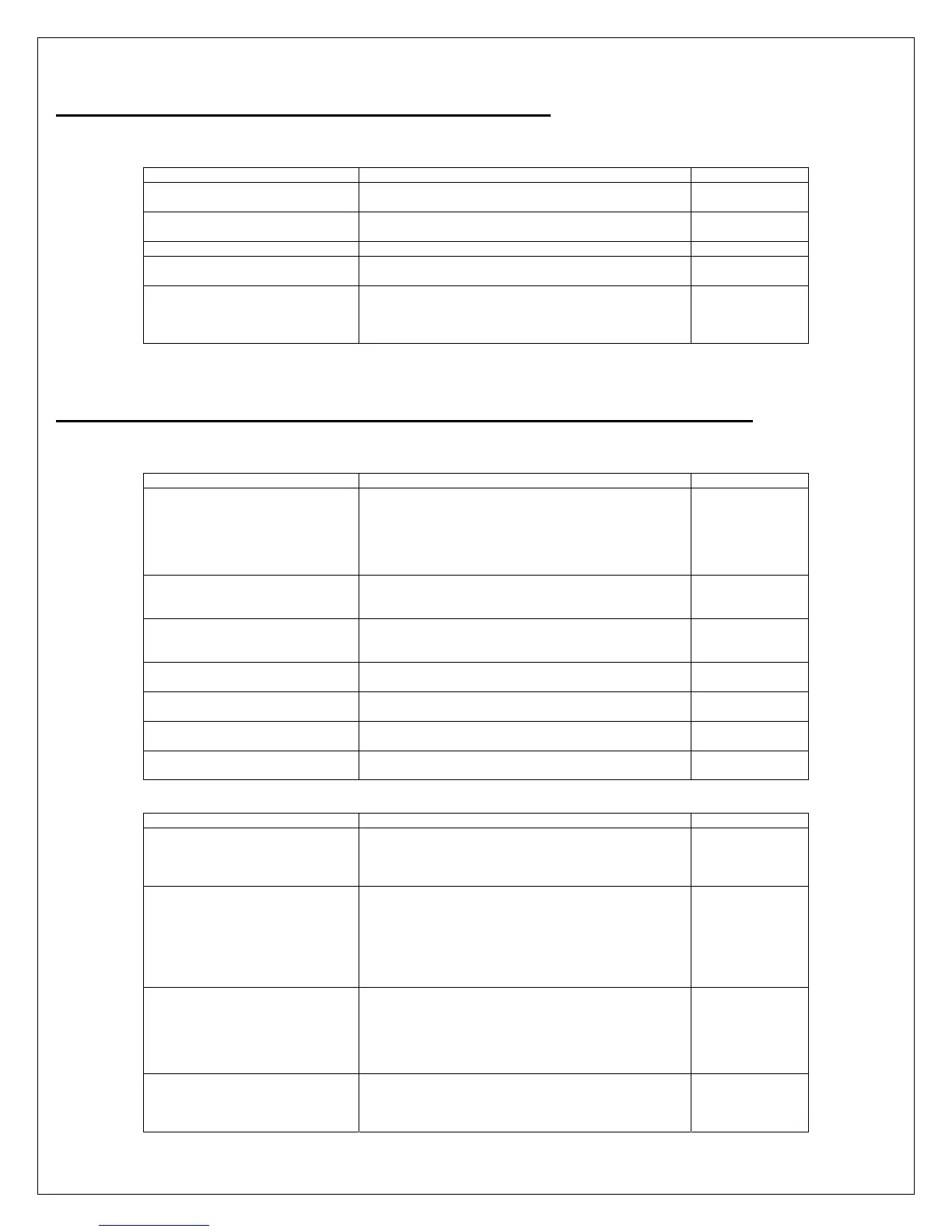

Table 4.18 – Lead Lag Slave Configuration Parameters

4-32 Lead Lag Master Configuration Parameters

Table 4.19 displays Lead Lag Master configuration parameters.

Refer to 5-14 LEAD LAG MASTER CONFIGURATION for Lead Lag Master parameter programming.

Parameter Comment Password

Master enabled Disabled: The master function is disabled.

Enabled: Enable the lead lag master.

Installer

LL CH setpoint This parameter provides the setpoint used during LL CH

demand.

Installer

LL CH TOD setpoint This setpoint is used when the time-of-day switch is on. Installer

Modbus port MB1, MB2 or No Port

Modbus port use for lead lag operation.

Installer

Modbus address 0-250

Modbus address used to communicate with the unit. This

address number must be unique for each burner on the

network.

Installer

Table 4.19 – Lead Lag Master Configuration Parameters

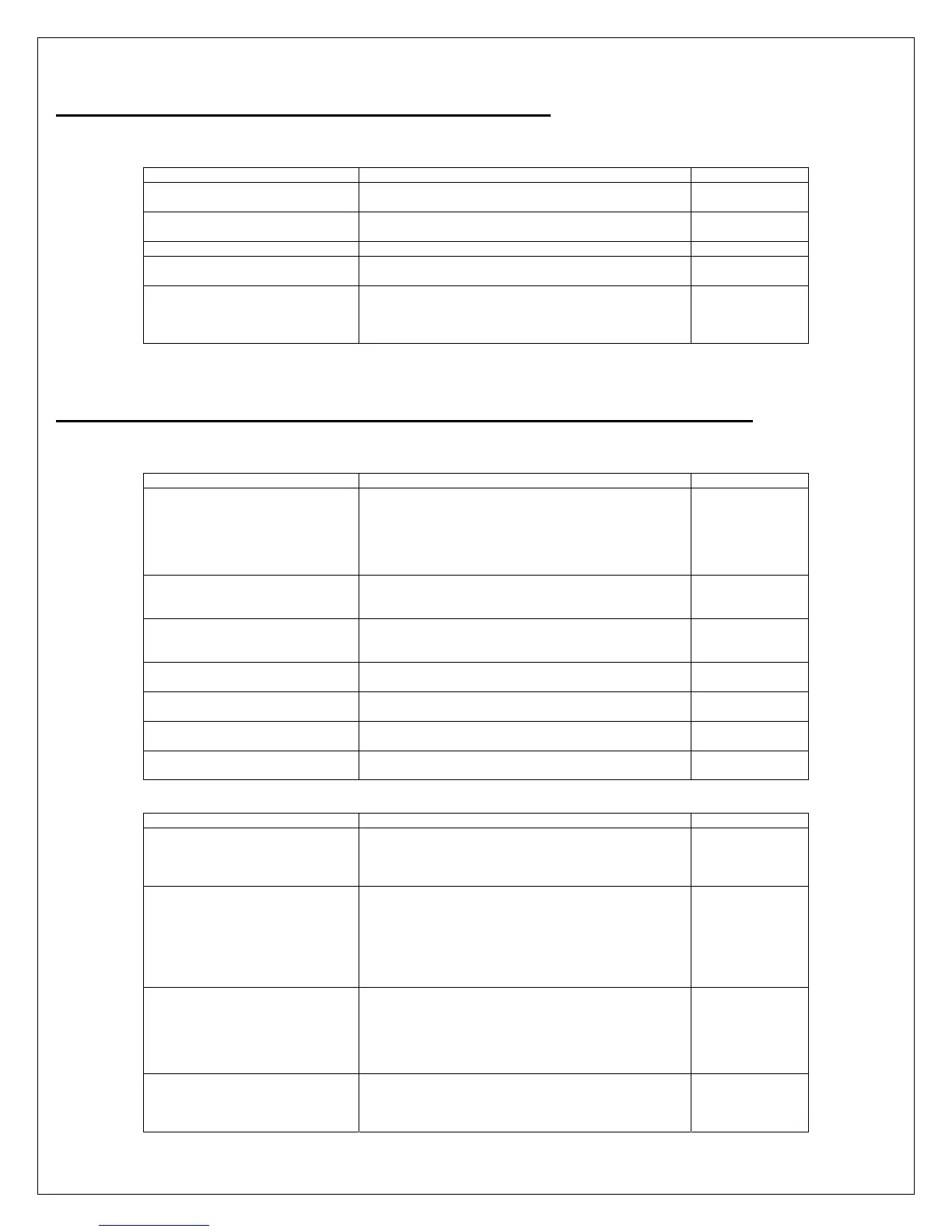

4-33 Lead Lag Master Configuration Parameters Advanced Settings

Following tables display Advanced Settings for Lead Lag Master configuration parameters.

Refer to 5-15 to 5-23 ADVANCED LEAD LAG CONFIGURATION for Lead Lag Master parameter programming.

Parameter Comment Password

Modulation backup sensor Select backup LL modulation sensor

Disable: No backup sensor will be used.

Lead outlet: Outlet temperature of the lead boiler will be

used as the backup sensor.

Outlet average: Average of the outlet temperatures of all

slave boilers that are firing will be used as a backup.

Installer

Off hysteresis Differential above setpoint when Last LL stage boiler is

turned off

2 °F to 30 °F (1 °C to 16 °C)

Installer

On hysteresis Differential below setpoint when First LL stage boiler is

turned on

2 °F to 30 °F (1 °C to 16 °C)

Installer

Hysteresis step time Time between hysteresis step changes

(0=Disable hysteresis stepping)

Installer

P-gain Proportional term of PID

0-400

Installer

I-gain Integral term of PID

0-400

Installer

D-gain

Differential term of PID

0-400

Installer

Table 4.20 – Lead Lag Advanced Setting: Modulation Parameters

Parameter Comment Password

Demand switch STAT terminal: the STAT input in the On condition

creates lead lag demand and it also must be on for

burner demand to exist; if it is off there is no demand.

Disable: Demand switch input is not used.

Installer

Setpoint source Local: Local setpoint is used as lead lag setpoint.

Modbus: Setpoint source from modbus communication

4-20mA: Setpoint is determined by the 4-20mA remote

input. Two parameters that determine the temperature at

the extremes (20mA and 4mA). If the 4-20mA signal is

invalid, then the setpoint source reverts to Local until the

4-20mA signal is stable again.

Installer

Time of day setpoint Setpoint when Time Of Day switch is on

32 °F to 240 °F (0 °C to 115 °C)

This setpoint is used when the time-of-day switch is on

If the Outdoor Reset function is active then this setpoint

provides one coordinate for the shifted outdoor reset

curve.

Installer

4 mA water temperature -40 to 266F (-40 to 130C)

This parameter provides the temperature for the

interpolation of 4-20mA curve. This value determines the

minimum possible value for the setpoint.

Installer

Loading...

Loading...