60

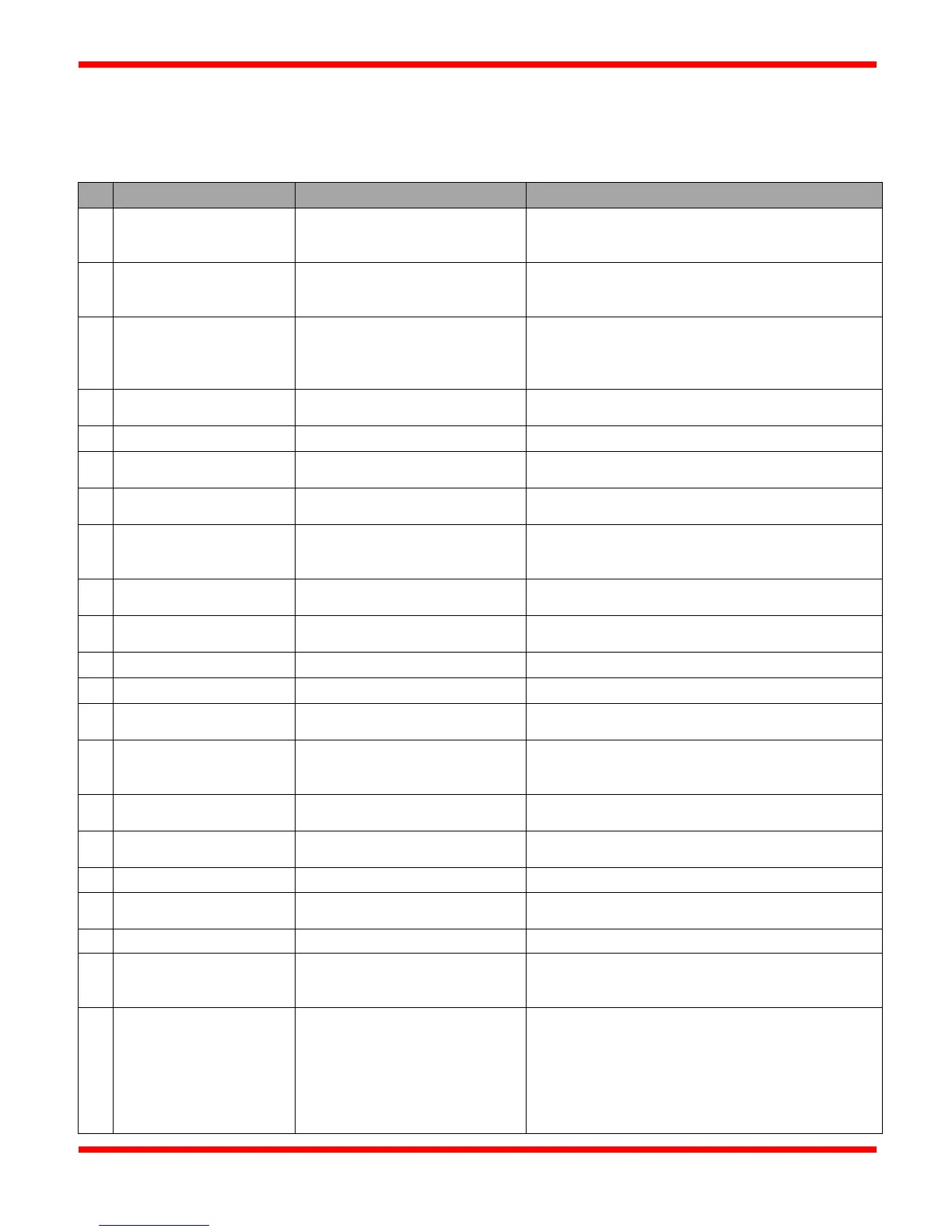

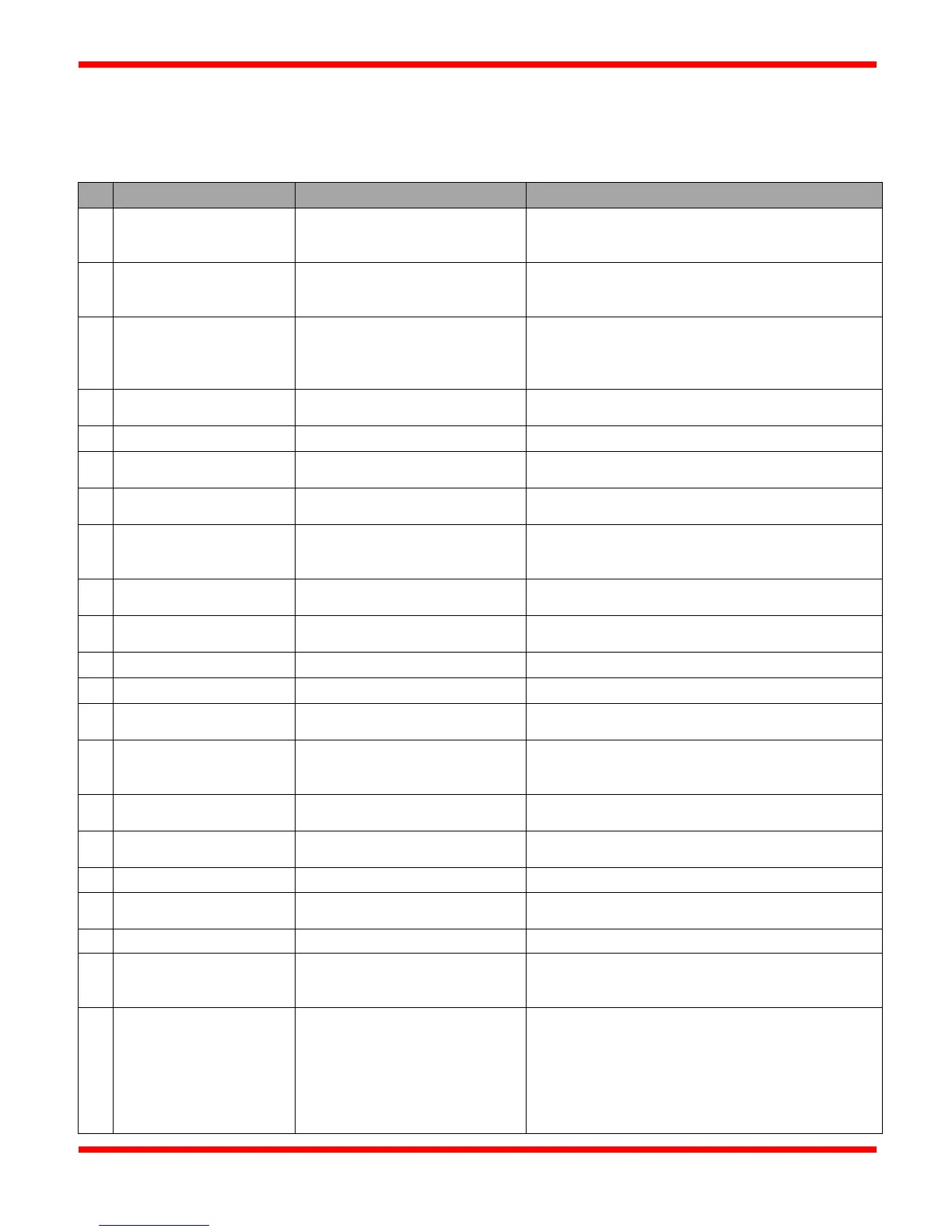

Appendix D - Troubleshooting

Burner Management Troubleshooting

Fails to attempt ignition

Check if the display is on or not: a menu screen or the

Status screen should always be displayed.

If Display is off, replace fuse with a 6.3A max fuse

Ensure that the minimum input voltage is 11.5VDC

(measured with a volt meter) for use with 2-3

Check all connections on the terminal strips. Ensure

that there are no short circuits, that the wires are

tightly gripped inside the terminals, and that the

screws on each terminal are tight.

POC terminal not closed, display

showing "POC"

Ensure that 12VDC is measured on both the POC+

and POC- terminals

Attempts ignition but

pilot doesn't light

Fuel gas supply to Pilot may be

too high or too low

Pilot fuel gas supply should be set at 5 pounds

Gap setting on ignitor/flame rod

not correct

Gap should be approximately 1/8" (3.175mm) and rod

tip needs to be cut to a sharp point

Ignition cable defective or

insulation worn

Check continuity through the ignition cable.

Multimeter should read close to zero ohms. If not,

cable needs to be replaced.

Ensure that good, thick ground connections are made

at the CSC400 and at the Pilot/burner valve.

Check supplied power to solenoid. Check gas flow

through solenoid.

Clean out Pilot orifice (Do Not redrill!)

Gap setting too wide or rod not

cut to a point

Shorten gap setting to approximately 1/8" (3.175mm)

and recut the ignitor rod tip.

Ignition cable defective or

insulation worn

Check continuity through the ignition cable.

Multimeter should read close to zero ohms. If not,

cable needs to be replaced.

Ensure that good, thick ground connections are made

at the CSC400 and at the ignitor tip.

Contaminated ignitor rod or Pilot

nozzle

Remove Pilot assembly, clean rod and nozzle, and

reinstall.

Solenoid valve not

opening

No power to solenoid valve or

faulty solenoid valve

Replace defective solenoid valve

then closes again

Driver setting for the attached

Verify that the Low Power Solenoid Driver DIP

switch settings are matched to the solenoid valves

Some larger solenoid valves rated for 12VDC require

an output voltage very near to 12VDC. Measure the

output voltage on the solenoid terminals to ensure that

it's sufficient (approx. >= 11.5VDC).

Higher current drawn on each solenoid output will

cause slightly higher voltage drops which may

interfere with solenoid operation. Input voltage may

Loading...

Loading...