Do you have a question about the AGFA Printer and is the answer not in the manual?

Specifications including width, height, depth, and weight for Anapurna XL and L models.

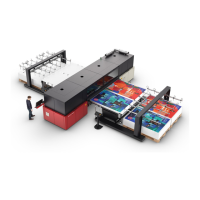

Identification of parts and their locations on the front of the printer.

Identification of parts and their locations on the rear of the printer.

Explanation of the safety sensor on the front and rear covers and its function.

Detailed view of the head carriage and the meaning of signal tower lights.

Details on the UV curable ink, its properties, and usage.

Information on the ink's color gamut and calculated color volumes.

Details on how the ink is packaged and the list of ink types available.

Details on main ink tanks, auto supply, and sub ink tank functionality.

Operation of ink valves and negative pressure for printing heads.

Monitoring and control of the head base plate temperature during operation.

Troubleshooting ink refill issues and managing the waste ink tank.

General information about the UV curing system, including sources and power.

Configuration of UV curing settings and operational sequences.

How UV curing is applied during uni- and bi-directional printing.

Details about the printing table, including conveyor belt and vacuum zones.

Procedure for adjusting the tension of the conveyor belt.

Maintenance tasks related to the printing table, including borderless printing.

Information on replacing the conveyor belt, which is a spare part.

Daily end-of-day procedures, shuttle positioning, and waste box.

Procedure for checking nozzle firing and performing a purge.

Steps to resolve nozzle failures through purging and pressure adjustments.

Routine weekly maintenance tasks and engine storage procedures.

Procedure for preparing the engine for extended periods of non-operation.

Steps to prepare the engine for printing after a long period of inactivity.

Setting up the printer for roll media using the auto feed system.

Operation of the take-up system for roll media.

Procedure for aligning roll media before printing.

Vacuum settings specifically for roll media.

Setting up the printer for rigid media using support tables.

Aligning rigid media using register pins and setting margins.

Vacuum settings for rigid media, activating vacuum tables.

Function and usage of front and rear media roller bars.

Procedure for automatically setting the head base height using the control program.

Overview of the main Anapurna Control Program window and its functions.

Details on configuring engine parameters via the setup menu.

How to check and adjust bi-directional alignment for print quality.

Adjusting step size, carriage speed, and feed speed for optimal printing.

Configuration of UV options, head gap, and restricted factory settings.

Overview of various tests available in the Test Menu for diagnostics.

Steps to prepare an image file using the Wasatch RIP for printing.

Steps to prepare the printer before starting a print job.

Procedure for loading and printing an image file using the control program.

Procedures for cancelling a print and using the purge function during jobs.

Guidelines for printing on heat-sensitive media to avoid head strikes.

Tips for ensuring rigid media corners stay flat using vacuum.

How to adjust image borders in Wasatch RIP for borderless printing.