Chapter 3 Calibration Procedures

Recommended Test Equipment

47

3

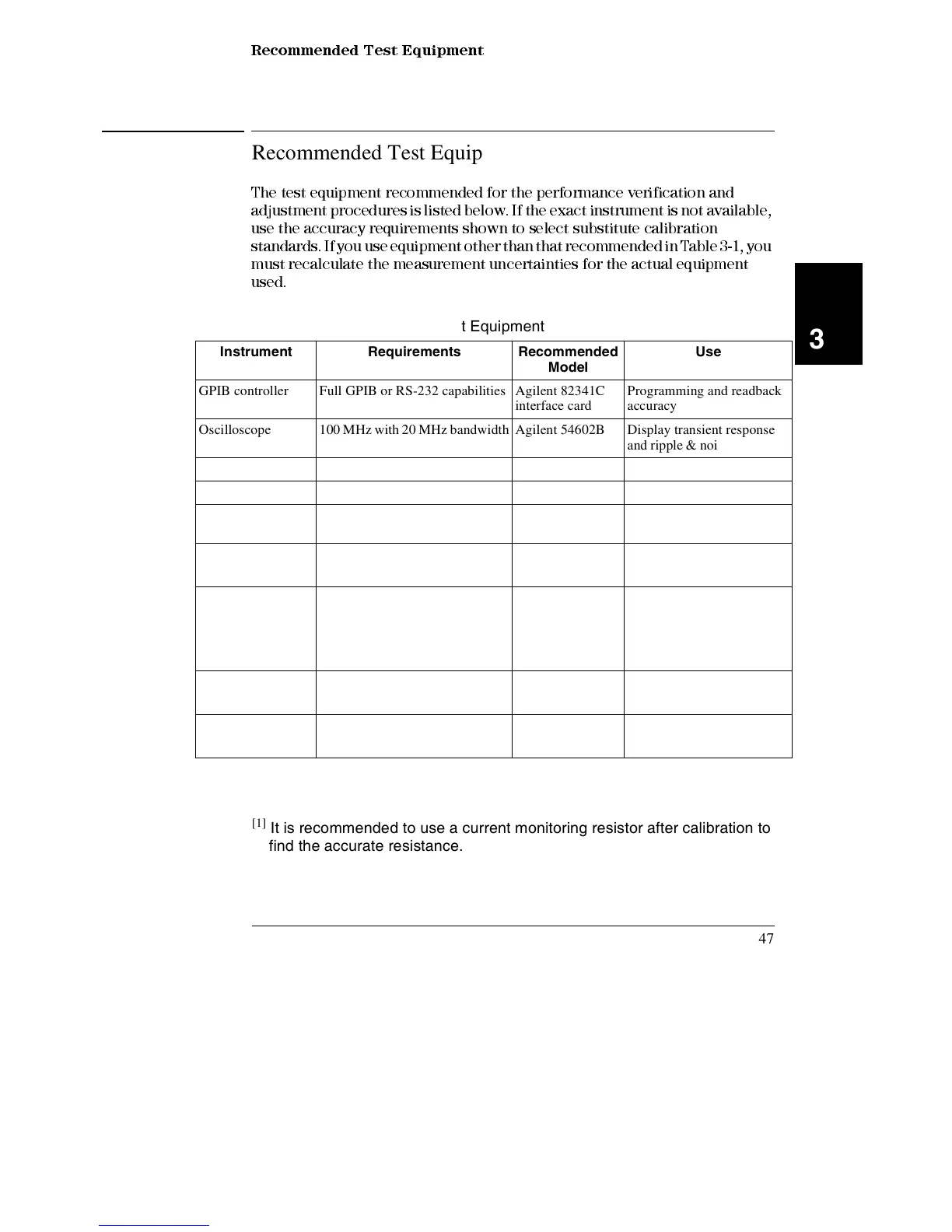

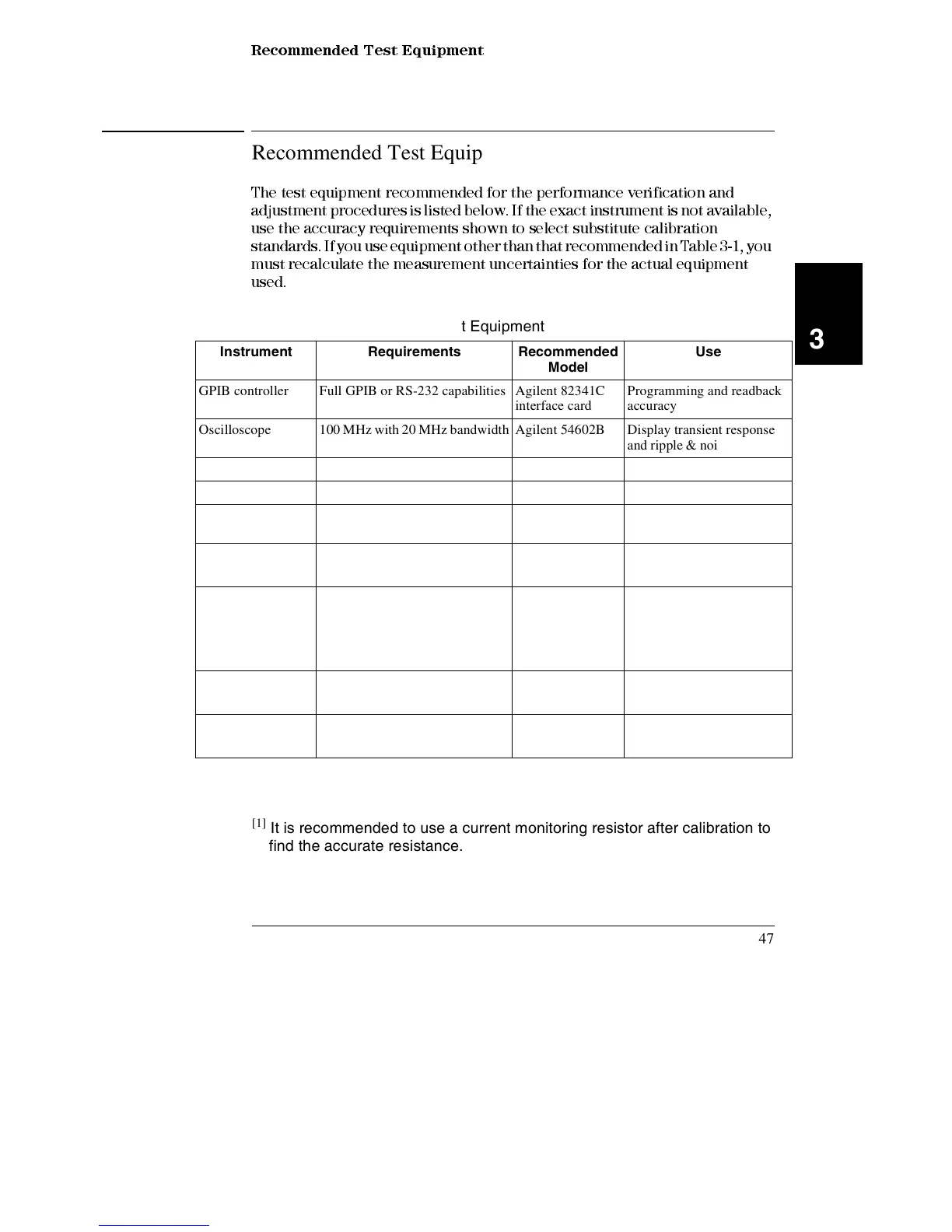

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not a vailable,

use the accuracy requ irem ents show n to select substitute calibr ation

standards. If you use equipment other than that recommended in T able 3-1, you

must recalculate the measurement uncertainties for the actual equipment

used.

Table 3-1. Recommended Test Equipment

[1]

It is recommended to use a current monitoring resistor after calibration to

find the accurate resistance.

Instrument Requirements Recommended

Model

Use

GPIB controller Full GPIB or RS-232 capabilities Agilent 82341C

interface card

Programming and readback

accuracy

Oscilloscope 100 MHz with 20 MHz bandwidth Agilent 54602B Display transient response

and ripple & noise waveform

RMS Voltmeter 20 Hz to 20 MHz Measure rms ripple & noise

Coaxial cable Agilent 10502A Measure rms ripple & noise

BNC female to

banana plug adapter

Agilent 1251-2277 Measure rms ripple & noise

Digital Voltmeter Resolution: 0.1 mV

Accuracy: 0.01%

Agilent 34401A Measure dc voltages

Electronic Load Voltage Range: 60 Vdc

Current Range: 60 Adc

Open and Short Switches

Transient On/Off

Agilent 60502B Measure load and line

regulations and transient

response time.

Resistive Loads

(R

L

)

(0.4 Ω, 300 W/2.0 Ω, 300 W)*

(3.5 Ω, 300 W/12.5 Ω, 300 W)**

Measure ripple and noise

Current monitoring

Resistor (Shunt)

(0.01 Ω, 0.1%)

[1]

ISOTEK Co.

Model: A-H

Constant current test setup

*For Agilent E3633A Model **For Agilent E3634A Model

Loading...

Loading...