70

Order online at www

.agilent.com/chem/store

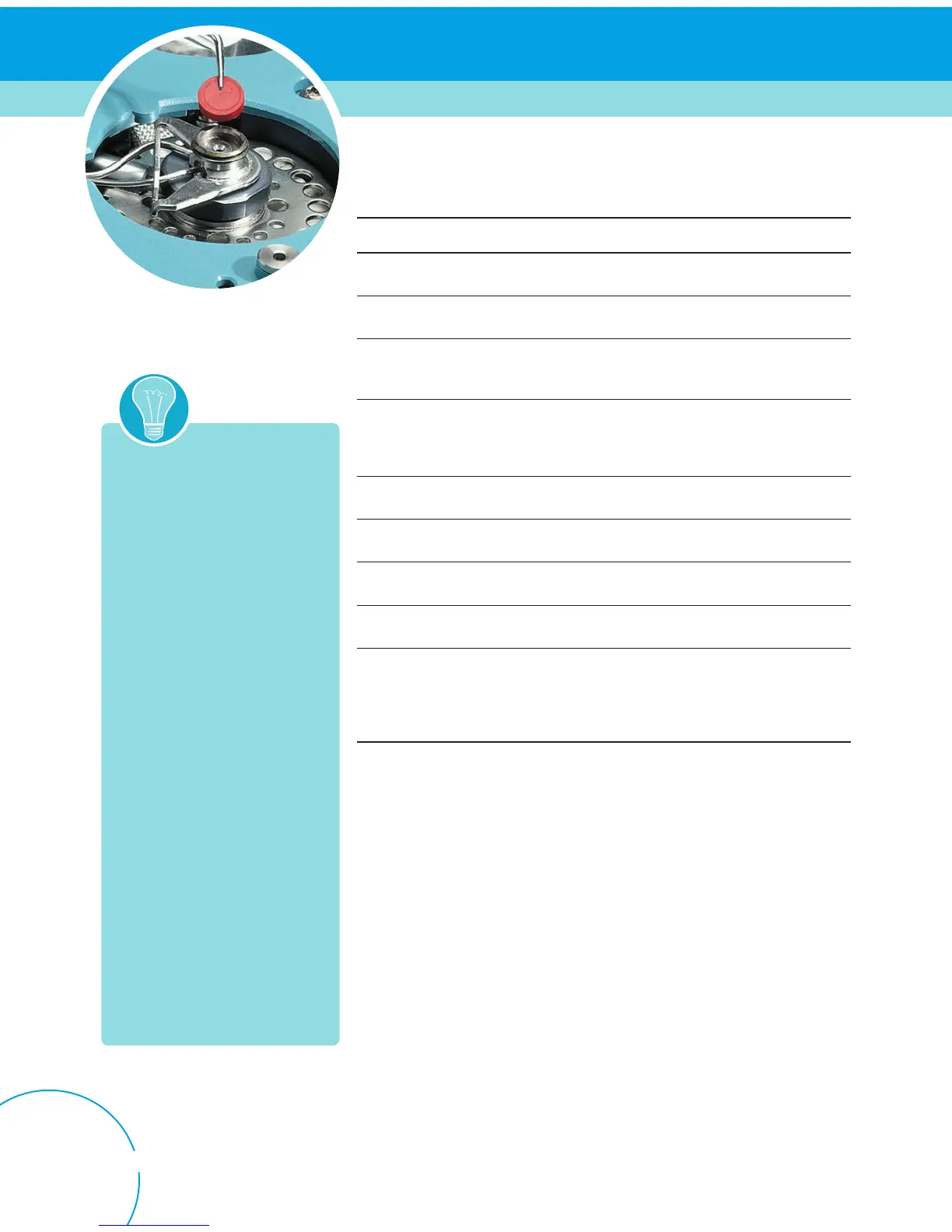

Cool On-Column Inlet Practices and Rationales

Parameter Selection/Setting Rationale

Initial inlet temperature Equal to or 3°C above column

oven temperture

Ensures sample focusing in

solvent front

Initial inlet temperature ramp Same as oven (oven track)

Faster than oven

Simple and effective

Narrows initial peak width

Injection volume 0.1 - 2.0 µL liquid Use smaller injections for small

ID columns

Depends on column capacity

Injection technique Automatically slower injection

Fused silica needle

Projects droplets away from

syringe tip

Use for manual injection into

small ID columns

Oven temperature Inlet temperature or slightly

lower

Prevents backflash

Column flow 50 - 80 cm/sec

30 - 50 cm/sec

Use for H

2

carrier gas

Use for He carrier gas

Septum purge 12 - 15 mL/min Use if installed to prevent

ghosting

Quantification All methods Inherently reproducible technique

Lack of discrimination

Retention gap requirements 1 - 3 m, deactivated

530 µm

Corrects peak distortion

Protects column from non-

volatile components

Permits autoinjection with

narrow-bore columns

There are some limitations to

cool on-column inlets, including

the following:

• Maximum sample volumes

are smaller compared with other

inlets (0.5 µL to 2.0 µL).

• Solute peaks eluting just before

the solvent cannot be focused

and are difficult to determine.

• Capilliary columns (especially those

with a large phase ratio or small

inner diameter) can be easily

overloaded with sample.

• Parameters such as initial column

temperature, solvent nature,

and injection rate must often

be optimized.

Tips & T

ools

Loading...

Loading...