31

3 Mechanical function 3.6 Axial seals – cooling system

The sealing element and wear ring must always

be flushed with liquid when the bowl rotates. The

seals are therefore supplied, through special

channels, with flushing water, and during the

CIP-period with CIP-liquid.

3.7 Axial seals –

cooling system

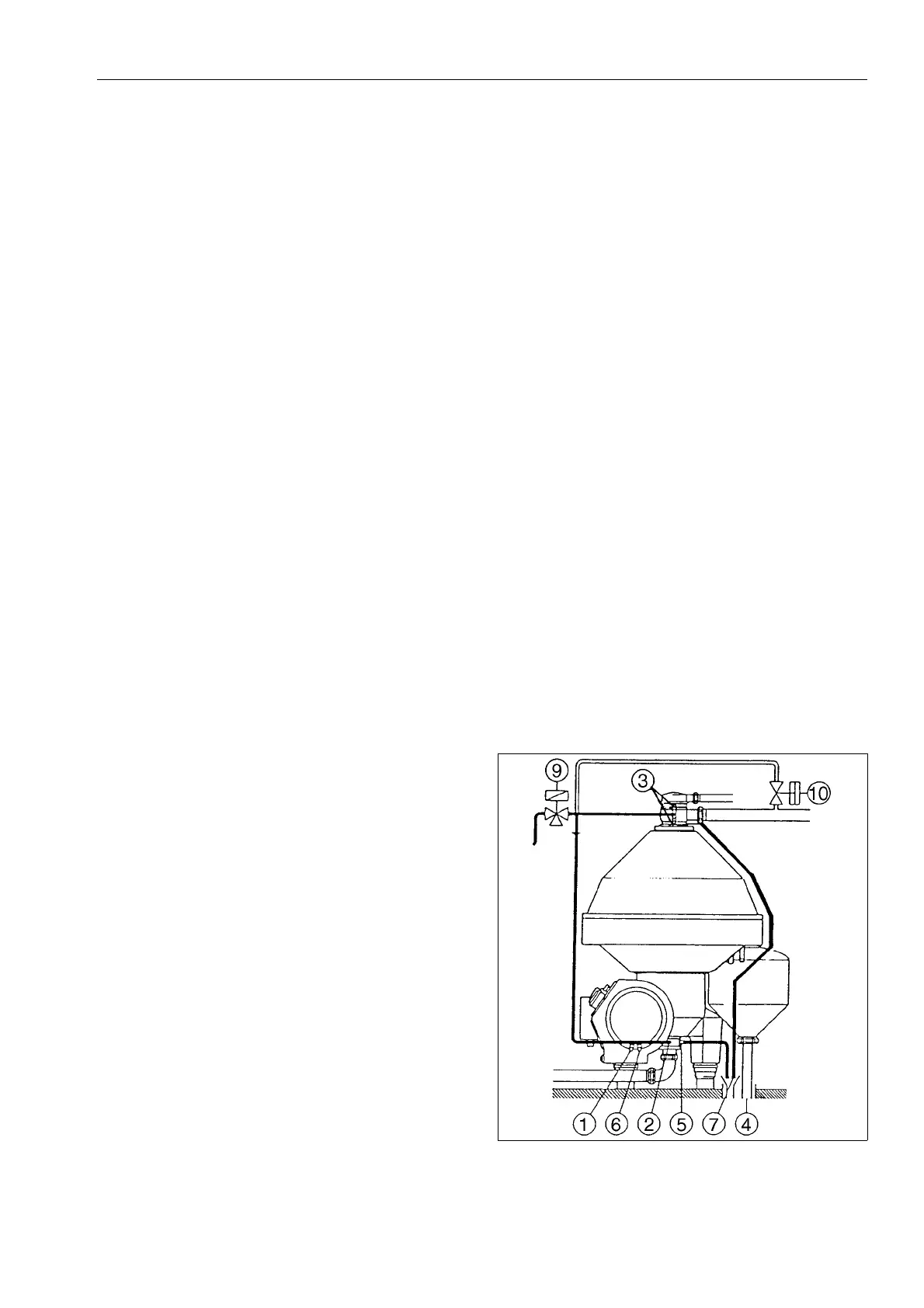

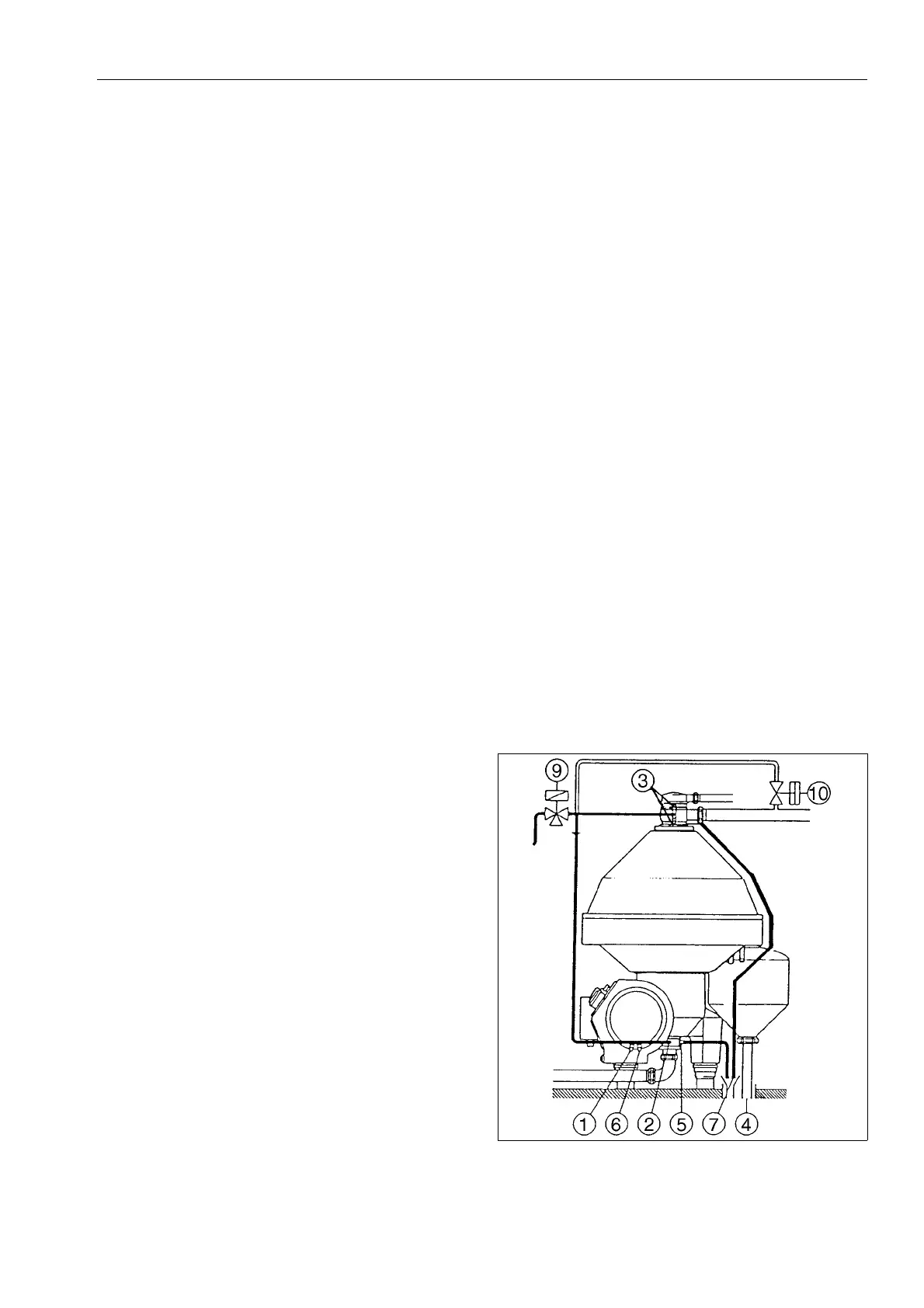

(The illustrations in this chapter show twin phase

separators)

During starting / separation / stopping periods

During the starting / separation / stopping periods,

cooling water is fed to the seals through

connections (2 and 3).

The cooling water from the outlet seals

discharges through the sediment outlet (4) and

pipe (7). From the inlet seals the water flows out

through outlet (5).

Water pressure and flow – see “Connection list” in

Installation Manual

.

1, 6 Cooling coil for oil bath.

2, 3 Cooling water inlet

4 Sediment outlet / cooling water outlet

5, 7 Indication tube for cooling water

9Valve *)

10 Valve

*) Normally included in the control unit cabinet.

Note: The indication tubes (5 and 7 in the figure)

provides an easy means of visual indication that

water is being supplied to the seals. Note that the

pipes (5 and 7) will also serve as an indication

pipe for seal leakage, if any.

G0695231

Loading...

Loading...